Slurry composition and lithium ion battery diaphragm containing same

A lithium-ion battery and composition technology, applied to battery components, circuits, electrical components, etc., can solve the problems of phase separation size and uniformity differences, can not effectively prevent the shrinkage of the base layer, insufficient resistance, etc., to reduce short circuits , Improve heat resistance and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

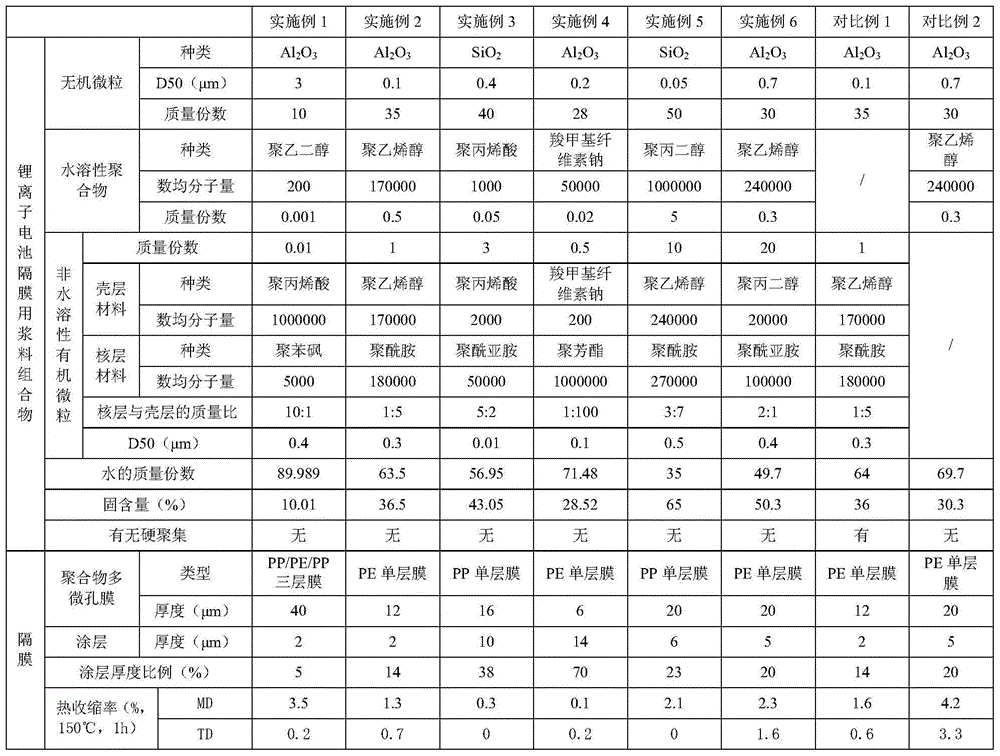

Examples

Embodiment 1

[0102] 1. Lithium-ion battery separator slurry composition

[0103] (1) Aqueous dispersion of inorganic particles

[0104] Take 1000gAl 2 o 3 Soak in 2500g water, use ball mill to make Al 2 o 3 After refining to small-sized particles with an average particle diameter of 3 μm, add 0.1 g of polyethylene glycol with a number average molecular weight of 200, and stir for 4 hours to obtain Al 2 o 3 water dispersion.

[0105] (2) Water-insoluble organic particles

[0106] 0.09g of polyacrylic acid with a number average molecular weight of 1,000,000 was dissolved in 0.9g of DMAc to obtain a polyacrylic acid solution; 0.91g of polyphenylsulfone with a number average molecular weight of 5000 was dissolved in 9.1g of DMAc to obtain a polyphenylsulfone solution; the polyacrylic acid solution Mix evenly with polyphenylsulfone solution to form an oil phase; under stirring conditions, quickly add 40g of water to the above oil phase, stir for 20 minutes, remove DMAc by ultrafiltration...

Embodiment 2

[0113] 1. Lithium-ion battery separator slurry composition

[0114] (1) Aqueous dispersion of inorganic particles

[0115] Take 350gAl 2 o 3 Soak in 500g water, use homogenizer to mix Al 2 o 3 After refining to small-sized particles with an average particle diameter of 0.1 μm, add 5 g of polyvinyl alcohol with a number average molecular weight of 170,000, and stir for 6 hours to obtain Al 2 o 3 water dispersion.

[0116] (2) Water-insoluble organic particles

[0117] 8.33g of polyvinyl alcohol with a number average molecular weight of 170,000 was dissolved in 138.8g of DMAc to obtain a polyvinyl alcohol solution; 1.67g of polyamide with a number average molecular weight of 180,000 was dissolved in 16.7g of DMAc to obtain a polyamide solution; the polyvinyl alcohol Mix the solution and the polyamide solution evenly to form an oil phase; under stirring conditions, quickly add 400g of water to the above oil phase, stir for 30 minutes, remove DMAc by ultrafiltration, contin...

Embodiment 3

[0124] 1. Lithium-ion battery separator slurry composition

[0125] (1) Aqueous dispersion of inorganic particles

[0126] Take 400gSiO2 2 Soak in 400g of water, use high-speed shearing machine to SiO 2 After refining to small-sized particles with an average particle diameter of 0.4 μm, add 0.5 g of polyacrylic acid with a number average molecular weight of 1000, and stir for 2 hours to obtain SiO 2 water dispersion.

[0127] (2) Water-insoluble organic particles

[0128] 8.6g of polyacrylic acid with a number average molecular weight of 2000 was dissolved in 86gDMAc to obtain a polyacrylic acid solution; 21.4g of a polyimide with a number average molecular weight of 50000 was dissolved in 142.7g of DMAc to obtain a polyimide solution; the polyacrylic acid Mix the solution with the polyimide solution evenly to form an oil phase; under stirring conditions, quickly add 500g of water to the above oil phase, stir for 60min, remove DMAc by ultrafiltration, and continue to concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com