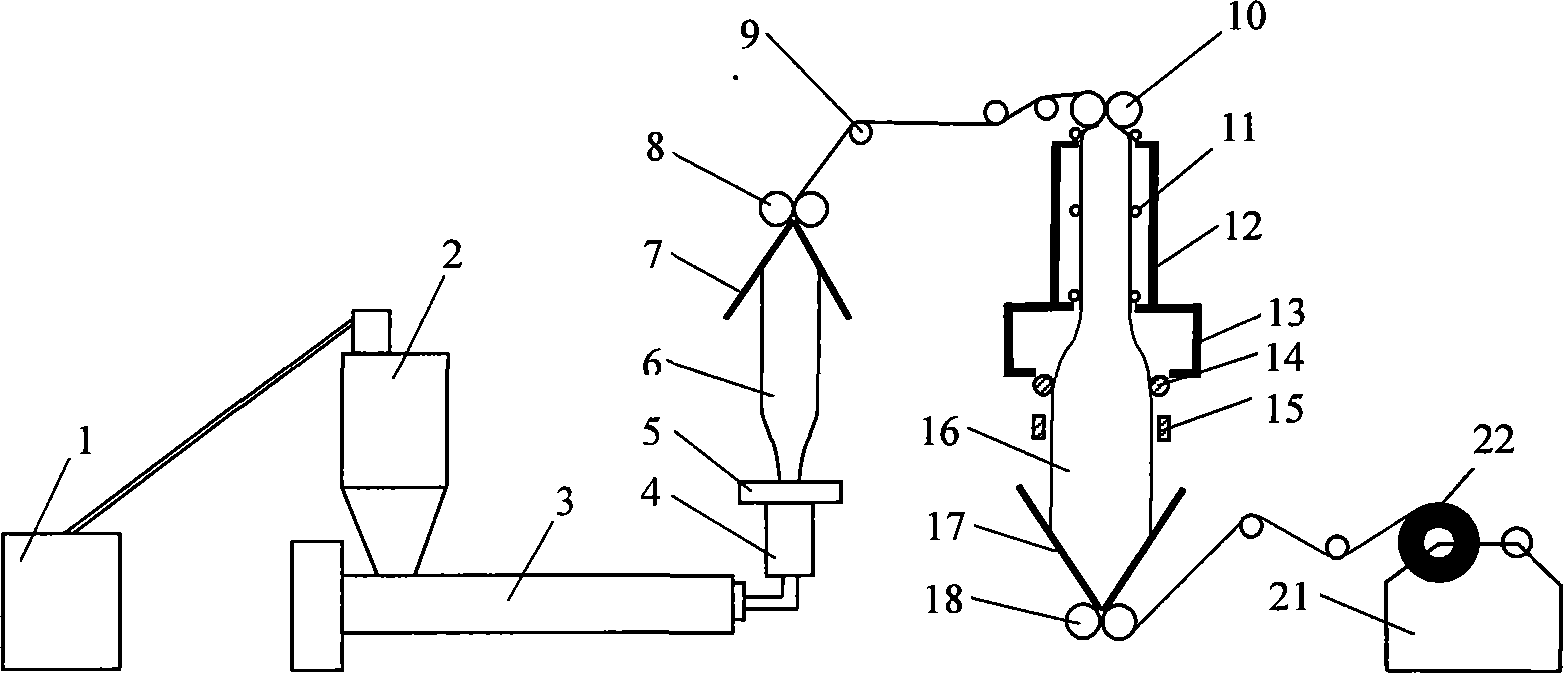

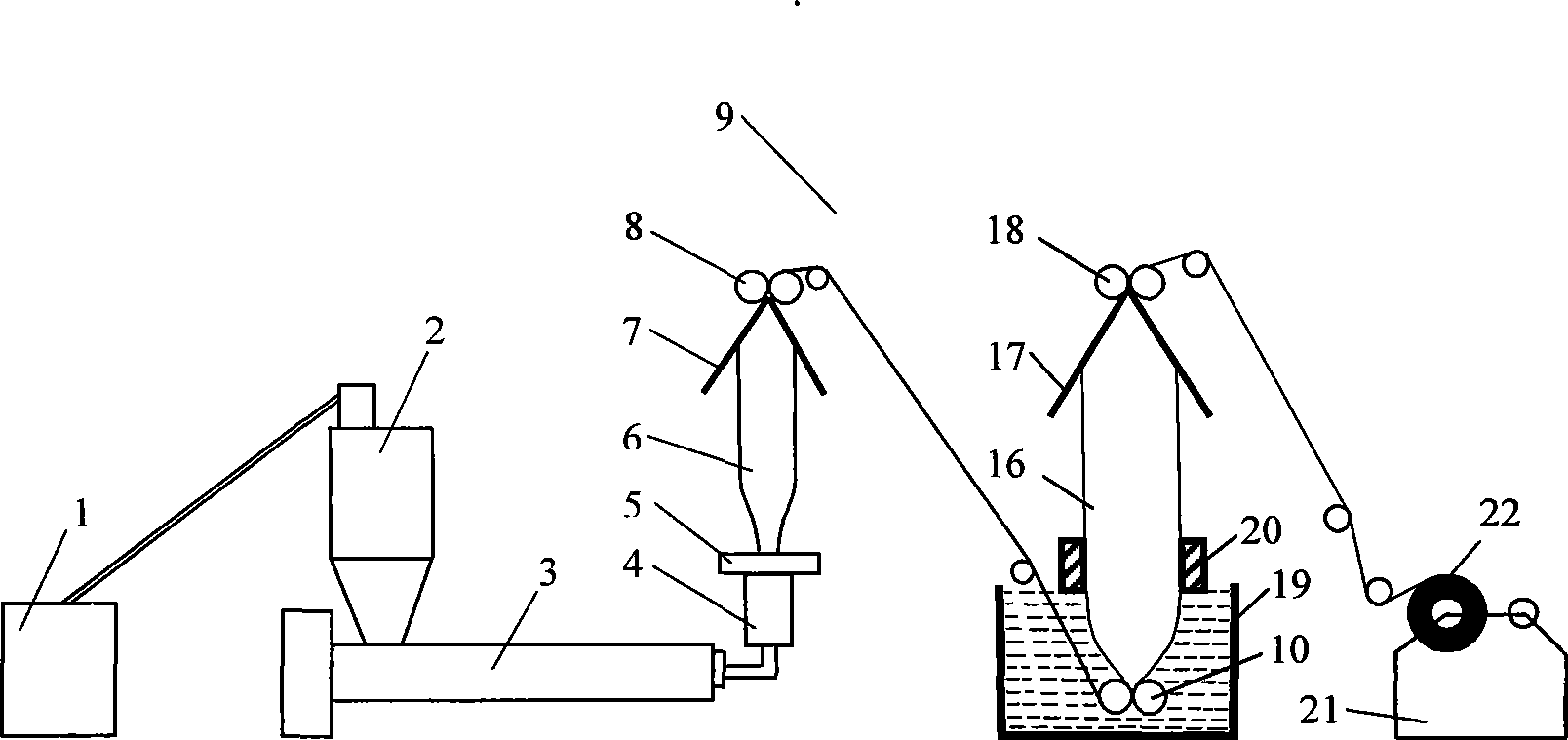

Double-bubble blown film moulding method for producing polyester thermal contraction film

A technology of heat-shrinkable film and molding method, which is applied in the field of double-bubble blown film forming of heat-shrinkable polyester film, can solve problems such as high product cost, lack of flexibility and adaptability, and lack of market competitive advantages, and achieve Reduce the overall cost of products, enhance market competitiveness, and easily adjust product specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The polyester raw material is PETG, the screw diameter is 65mm, the length-to-diameter ratio is 33, the die diameter of the blow molding head is Φ100, and the far-infrared heating is used for secondary inflation. The drying temperature of raw materials is 68°C. It is 3-stage temperature control, and the temperature is set at 85°C, 85°C, 90°C. The large-diameter oven is 1-stage temperature control, and the temperature is set at 170°C. The secondary inflation ratio is 2.2, and the secondary stretching ratio is 1.03 to obtain a finished film with a folded diameter of 610mm. After testing, the thermal shrinkage rate in the transverse direction is 51%, and the thermal shrinkage rate in the longitudinal direction is 3.0%.

Embodiment 2

[0039] The polyester raw material is PETG, the screw diameter is 65mm, the length-to-diameter ratio is 33, the die diameter of the blow molding head is Φ100, the water bath heating is used for secondary inflation, the drying temperature of the raw material is 68°C, and the heating temperature of the water tank is set at 87°C. ℃, the secondary inflation ratio is 2.3, and the secondary stretching ratio is 1.02 to obtain a finished film with a folded diameter of 615 mm. After testing, the thermal shrinkage rate in the transverse direction is 52%, and the thermal shrinkage rate in the longitudinal direction is 2.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Screw diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com