Process for preparing modified cotton fibre

A technology for modifying cotton and fiber, which is applied in fiber processing, textiles and papermaking, etc. It can solve the problems of destroying the original appearance and being difficult to achieve, achieve good biocompatibility, expand application fields, improve wearability and added value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

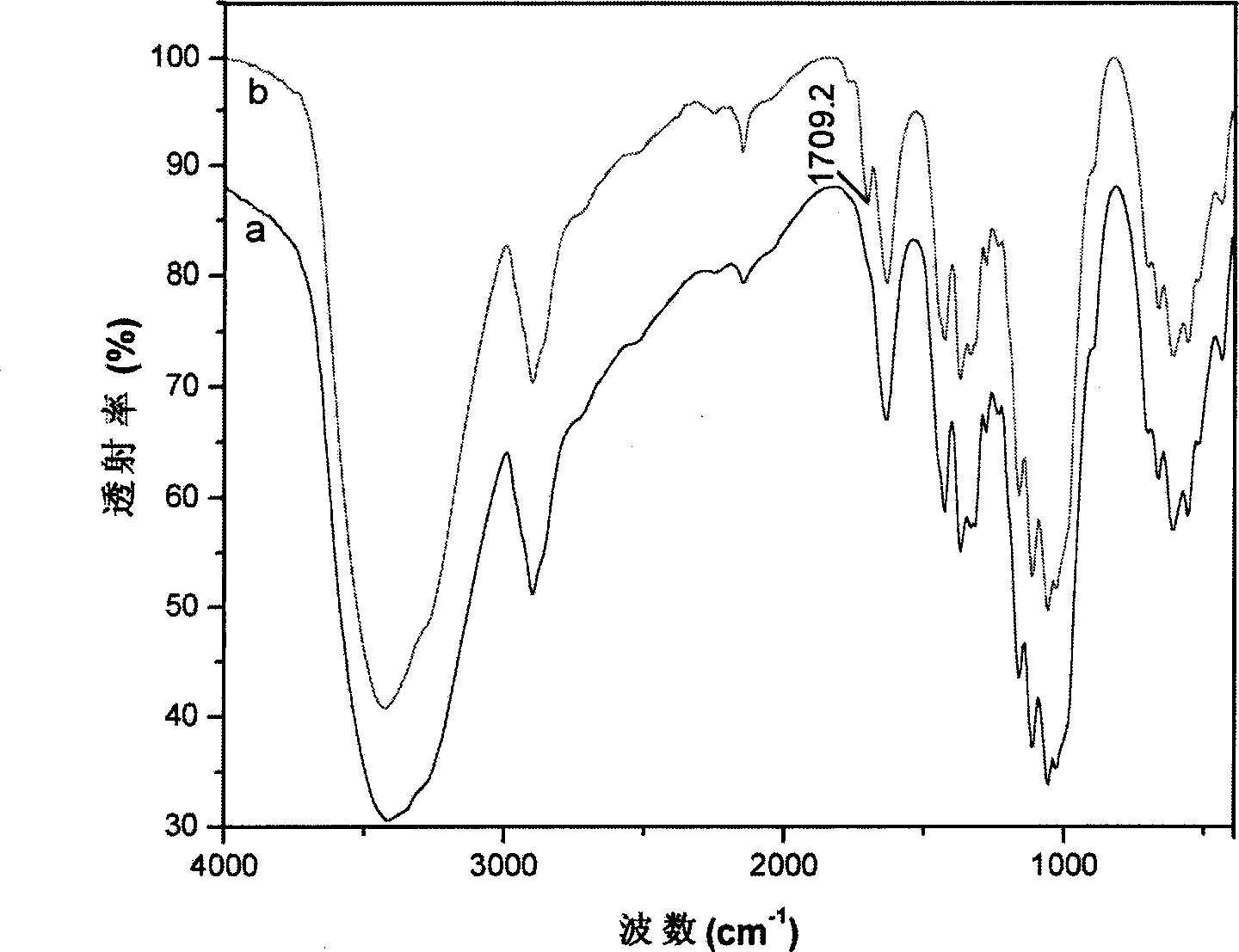

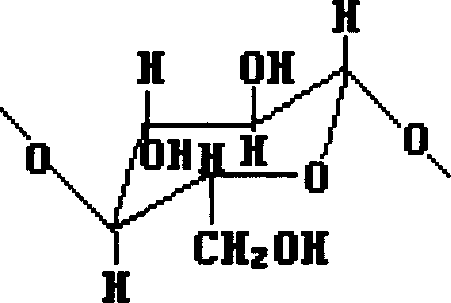

[0019] The twisted 50.5 Tex cotton yarn is scoured with caustic soda to remove impurities, and then bleached with hydrogen peroxide. Then put the cotton yarn into the sodium periodate solution with a concentration of 1g / L, keep the temperature of the reaction solution at 55°C, stir and treat it for 1 hour under the condition of bath ratio 1:200, take it out, and use 0.1mol / L glycerine Soak in alcohol solution for 30 minutes; soak in water at room temperature for 24 hours to remove the oxidant on the cotton fiber, dehydrate after washing with warm water for several times, you can get the oxidized cotton fiber that keeps a certain strength and elongation (breaking strength decreases by 14%, elongation rate decreased by 7%); before the above-mentioned selective oxidation reaction, the molecular structure of cotton fiber is

[0020]

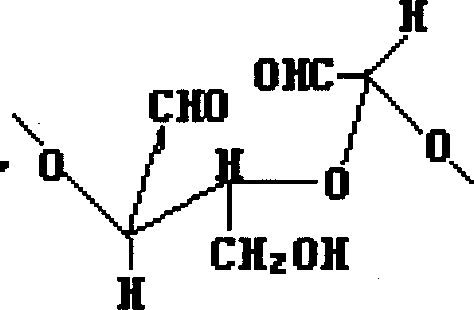

[0021] , in C 2 and C 3 The position is the secondary hydroxyl group, in the selective oxidation reaction, the IO in the periodate 4 - C in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com