High tenacity, high modulus filament

A high-modulus, high-tenacity technology, applied in the direction of spinneret assemblies, single-component polyolefin artificial filaments, defenses, etc., can solve the problems of increased difficulty in high-strength yarns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 6

[0048] Yarn Preparation and Tensile Properties

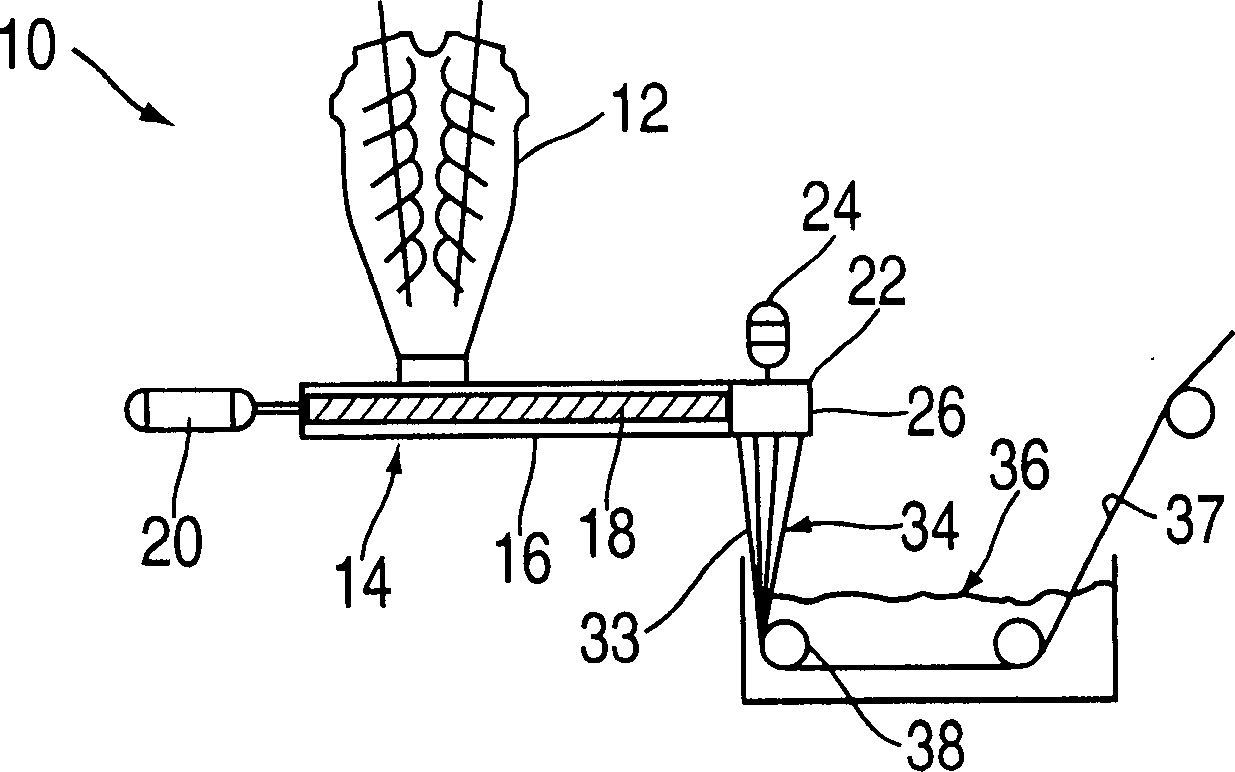

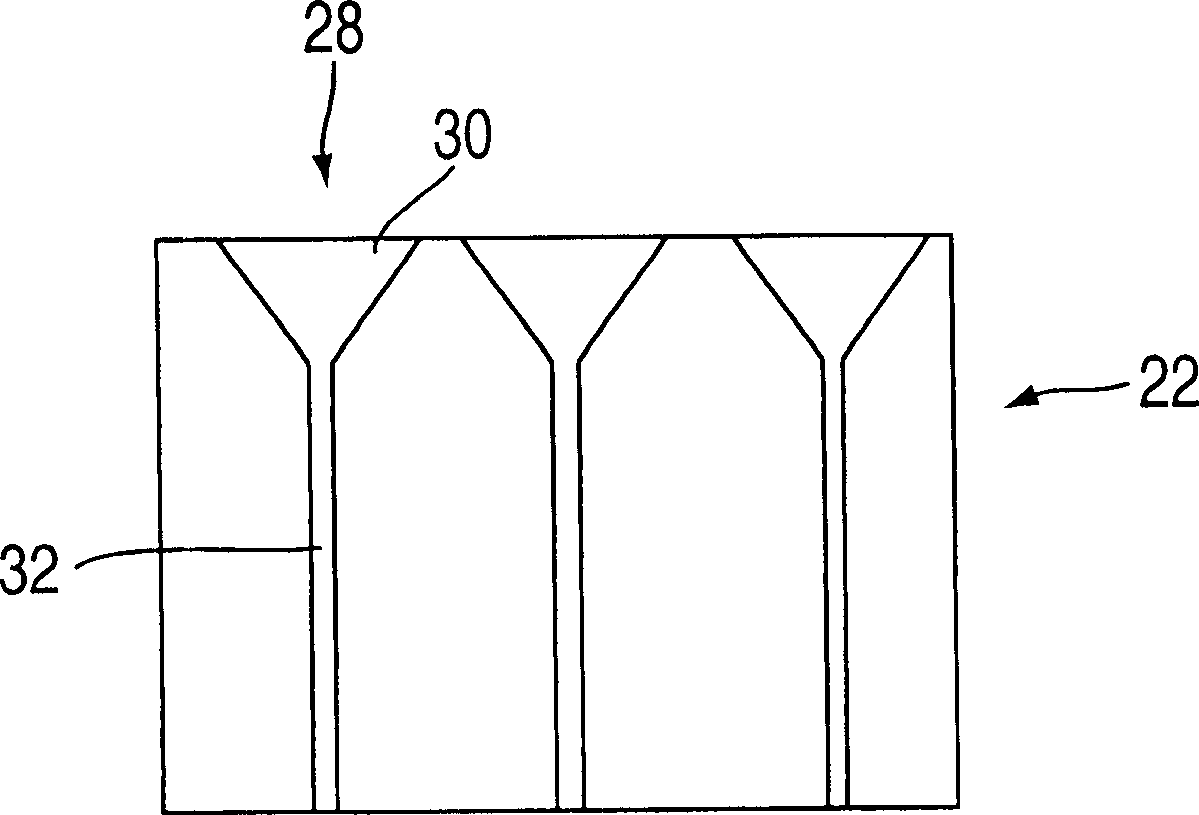

[0049] A slurry of 8.0 wt% polyethylene in mineral oil was fed into a co-rotating Berstorff twin-screw extruder with a diameter of 40 mm and a length to diameter ratio of 43:1. Polyethylene has an intrinsic viscosity of 27 and contains no detectable branching (less than 0.2 methyl groups per 1000 carbon atoms). The polyethylene dissolves in the mineral oil as it passes through the extruder. The polyethylene solution flowing out from the extruder passes through a gear pump and enters a 60-filament spinneret whose temperature is maintained at 320°C. The diameter of each hole of this spinneret was 1 mm, and the aspect ratio was 40 / 1. The volumetric flow rate through each orifice was 1 cc / min. The extruded solution filaments passed through a 3.2 mm air gap, where they were stretched 15:1, and then entered into a water quench bath at 9°C. The air velocity generated by natural convection in the transverse direction of the filame...

Embodiment 7A

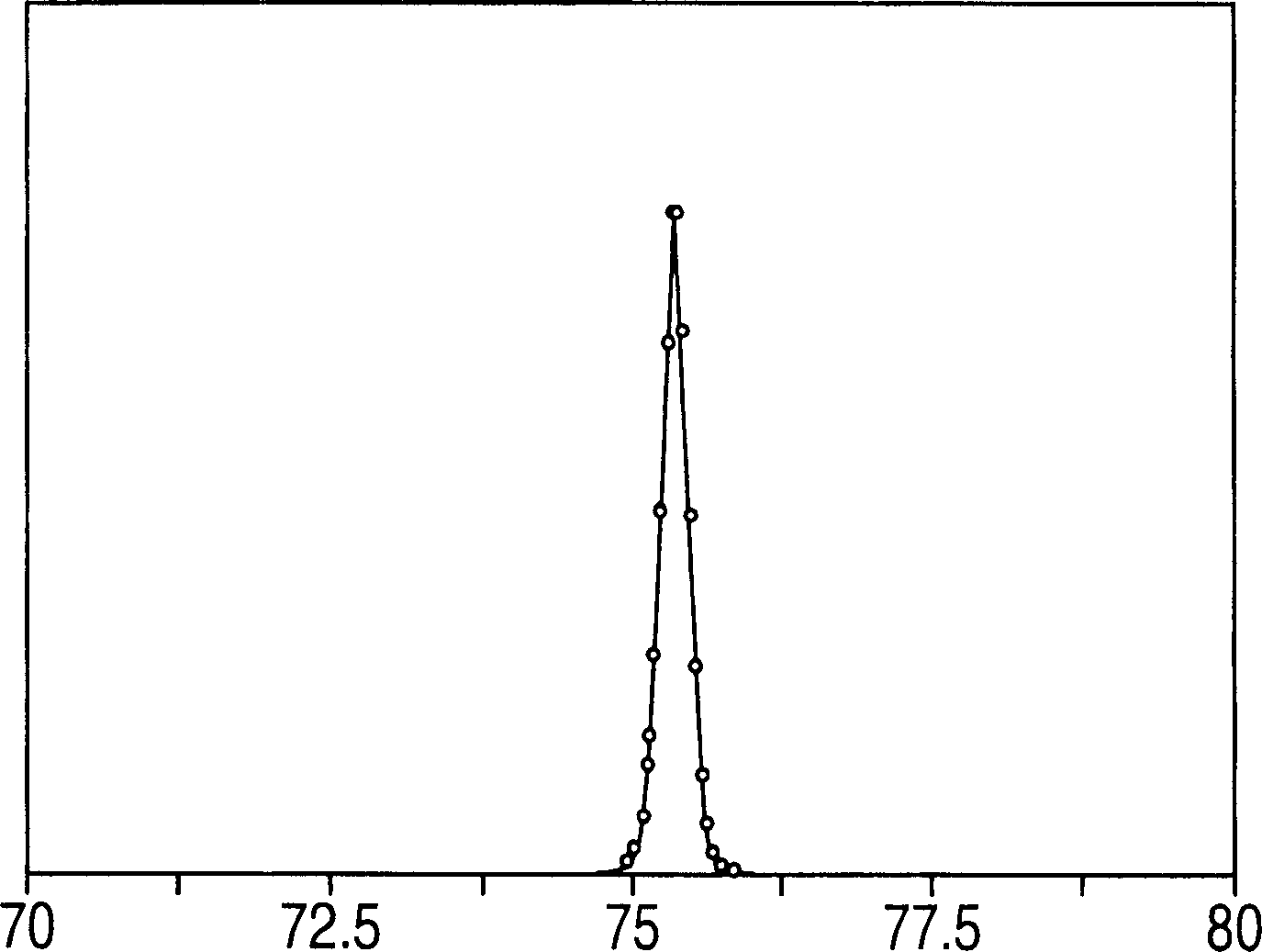

[0055] Example 7A. High Strain Crystalline Components

[0056] The microstructure of the prior art yarns and the yarn of Example 6 was analyzed by wide angle x-ray diffraction. Fig. 3 a has listed under the condition of -60 ℃ and no load, the meridian scanning curve of the 002 diffraction peak of commercial SPECTRA ® 1000 yarn produced by Honeywell International Company; The same peak under the condition of line breaking strain. It can be seen that the 002 reflection has been displaced and split. Higher angle peaks correspond to low strain crystalline components, while lower angle peaks correspond to high strain crystalline components. The proportion of highly strained crystalline components was 58% (measured by relative peak area).

[0057] Figure 4 The meridional scan curve of the 002 diffraction peak of DYNEEMA(R) SK77 high modulus polyethylene yarn at -60°C and the tensile strain just below the breaking strain is shown. It can be seen that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tenacity | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Work of fracture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com