Method for preparing aromatic polysulphonamide fibers

A polyarylsulfone amide and fiber technology, which is applied in fiber treatment, fiber chemical characteristics, stretch spinning, etc., can solve the problems of low mechanical properties of fibers, difficult stretching of as-spun silk, unfavorable filament orientation structure, etc. Achieve the effects of molecular orientation and crystallization fully, high temperature draw ratio reduction, and increase spinning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

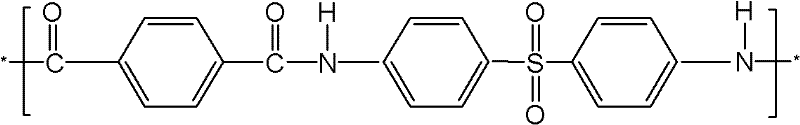

[0039] Spinning solution with an apparent viscosity of 20 Pa·s and a mass fraction of polyarylsulfoneamide of 12%, wherein polyarylsulfoneamide is a random composition composed of units of structural formula (1) and structural formula (2) at a molar ratio of 1:3. Copolymerized polyarylsulfoneamide, the solvent is dimethylformamide containing 20% calcium chloride by mass fraction, sprayed into the coagulation bath after passing through the spinneret hole and a 20mm air layer at 60°C, the composition of the coagulation bath is 70wt % of dimethylformamide solvent containing 15% calcium chloride by mass fraction and the balance of water, the temperature is 40°C, the extrusion speed at the spinneret is 8m / min, and the drawing speed of the coagulation bath is the same as that of the spinneret extrusion The output rate ratio is 1.8 times. Then enter successively two stages of plasticizing stretching baths with different concentration gradients and two stages of washing stretching b...

Embodiment 2

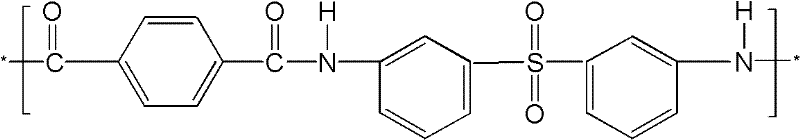

[0041]Spinning solution with an apparent viscosity of 65Pa·s and a mass fraction of polyarylsulfoneamide of 18%, wherein polyarylsulfoneamide is a random composition composed of units of structural formula (3) and structural formula (4) in a molar ratio of 4:1. Copolymerized polyarylsulfoneamide, the solvent is dimethylacetamide containing 25% calcium chloride by mass fraction, sprayed into the coagulation bath after passing through the spinneret hole at 60°C and passing through a section of 80mm air layer, the composition of the coagulation bath is 55wt % of dimethylacetamide solvent containing 20% calcium chloride by mass fraction and the balance of water, temperature 10°C, extrusion speed at the spinneret is 4m / min, the drawing speed of the coagulation bath is the same as that of the spinneret extrusion The output rate ratio is 5 times. Then enter successively two stages of plasticizing stretching baths with different concentration gradients and two stages of washing stre...

Embodiment 3

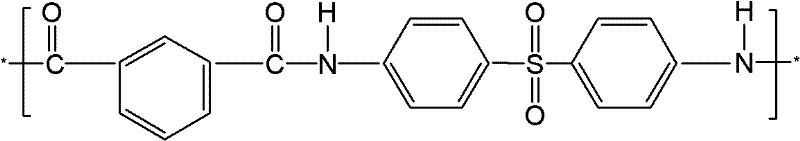

[0043] Spinning solution with an apparent viscosity of 98 Pa·s and a mass fraction of polyarylsulfoneamide of 5%, wherein polyarylsulfoneamide is a homopolymerized polyarylsulfoneamide composed of units of structural formula (1), and the solvent is 1-butyl -3-Methylimidazolium chloride salt, sprayed into the coagulation bath after passing through the spinneret hole and a 40mm air layer at 80°C, the coagulation bath composition is 60wt% 1-butyl-3-methylimidazolium chloride salt solvent And the remaining water, the temperature is 5°C, the extrusion speed at the spinneret is 20m / min, and the ratio of the drawing speed out of the coagulation bath to the extrusion speed of the spinneret is 2.5 times. Then enter into two stages of plasticizing and stretching baths with different concentration gradients and two stages of water washing and stretching baths with different temperature gradients, including: the first stage of plasticizing and stretching baths consists of 40wt% 1-butyl-3-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com