Static spinning device and its industrial use

A technology of electrospinning and spinning device, which is used in textile and papermaking, filament/thread forming, fiber processing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

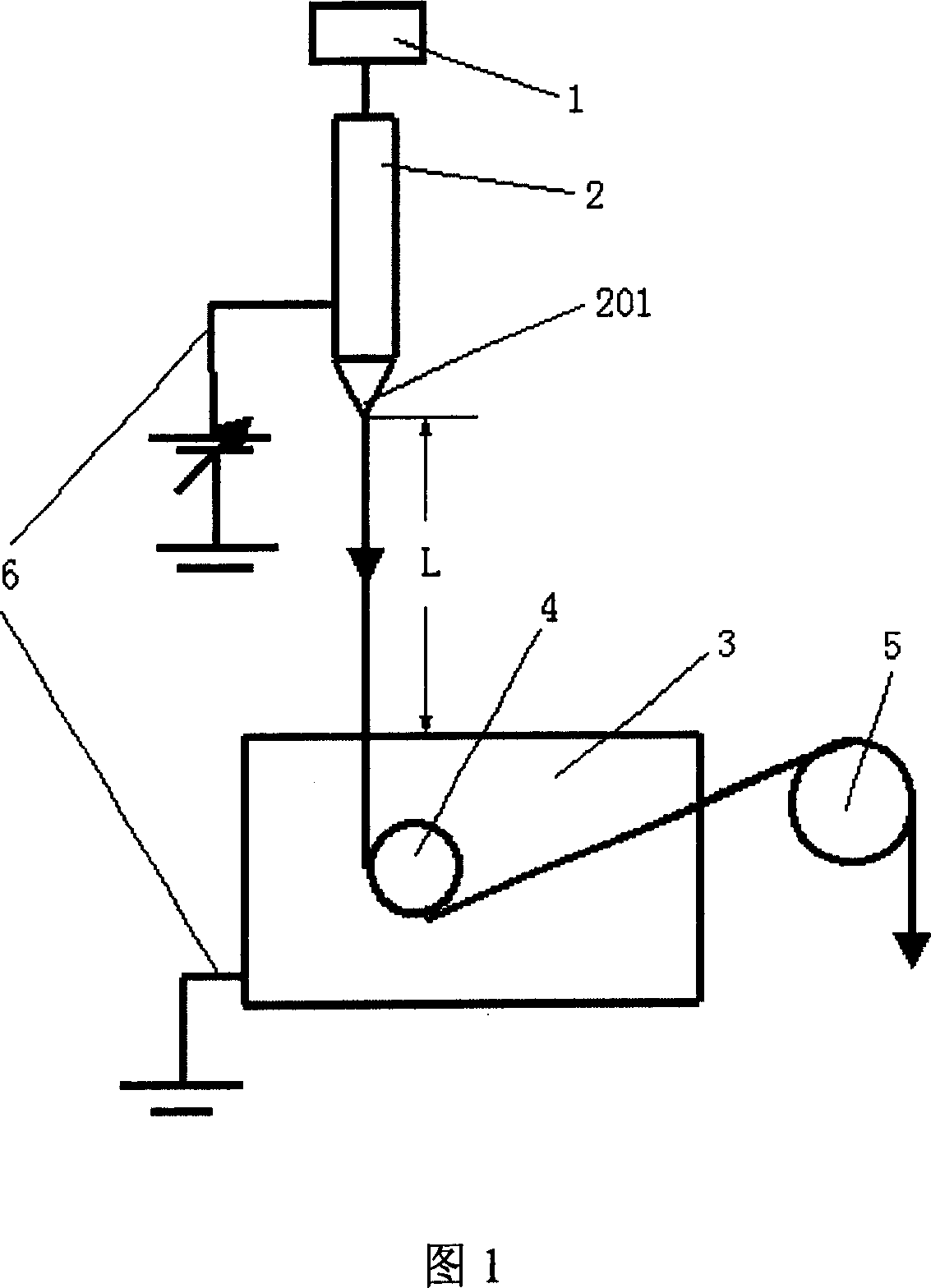

[0035] Spinning was carried out using the apparatus shown in Figure 1. Wherein: spinneret aperture is 1 μm; The length of coagulation bath 3 is 4m, and spinneret distance L is 10cm apart from coagulation bath liquid surface;

[0036] The concentrated sulfuric acid solution of polyhexamethylene terephthalamide with a mass concentration of 1wt% is sent into the spinneret that is provided with spinneret hole by metering pump, is extruded from spinneret hole, and the solution that is squeezed out is in Under the action of electrostatic force, a thin stream of solution is formed, and the thin stream of solution moves forward at a high speed. The volatilization of the solvent and the drafting of the thin stream lead to the solidification of the thin stream of solution and the reduction of its diameter. During this process an orientation behavior takes place for the polymer chains. After the solution trickle moves for a certain distance, it enters the coagulation bath. In the coagul...

Embodiment 2

[0045] Spinning was carried out using the apparatus shown in Figure 1. Wherein: spinneret aperture is 2mm; The length of coagulation bath 3 is 3m, and spinneret distance L is 30cm apart from coagulation bath liquid surface;

[0046] Be that the dimethylacetamide solution of the polym-phenylene isophthalamide that mass concentration is 20wt%, adopt the same method of embodiment 1 to carry out spinning;

[0047] Said coagulant is a specific gravity of 1.336 containing dimethylacetamide and CaCl 2 (calcium chloride) in water;

[0048] Spinning voltage: 40KV, solution discharge rate: 10ml / h, medium temperature around solution trickle: 80°C, solution trickle movement speed: 20m / s, coagulation bath temperature: 20°C, guide roller speed: 0.5m / s.

[0049] Adopt ASTM standard D 638 to detect the obtained fiber, the results are as follows:

[0050] Young's modulus 3 ~ 5MPa

[0051] Yield modulus 1 ~ 3MPa

[0052] Elongation at break: 300-500%

[0053] Breaking strength: 4~6MPa

Embodiment 3

[0055] Adopt the method identical with embodiment 1, wherein: solution is the dimethylacetamide+2~5% LiCl solution of polyparabenilamide, and said coagulating agent is that specific gravity is 1.238 containing dimethylacetamide and LiCl ( Lithium chloride) aqueous solution adopts ASTM standard D 638 to detect the fiber obtained, and the results are as follows:

[0056] Young's modulus 3 ~ 5MPa

[0057] Yield modulus 1 ~ 3MPa

[0058] Elongation at break: 300-500%

[0059] Breaking strength: 4 ~ 6Mpa

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com