Bobbin holder

A bobbin holder and bobbin tube technology, applied in the field of bobbin holders, can solve problems such as short running time of bobbin holders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

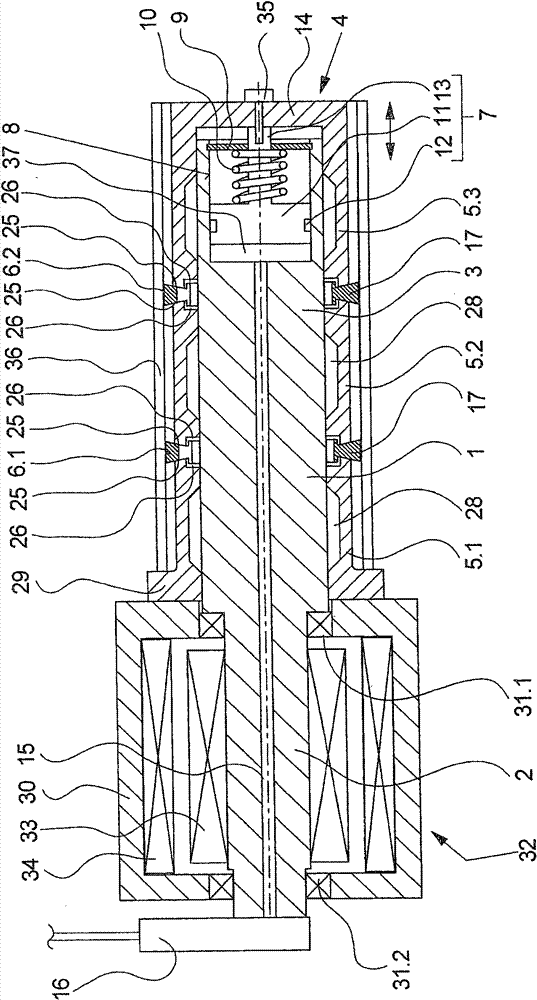

[0025] exist figure 1 A first embodiment of the bobbin holder according to the invention is schematically shown in sectional view in FIG. The bobbin holder has a drive shaft 1 with a bearing end 2 and an overhanging tensioning end 3 . Tensioning means 4 are held on the overhanging tensioning end 3 of the drive shaft 1 in order to tension a bobbin 36 on the circumference of the tensioning end 3 of the drive shaft 1 .

[0026] The tensioning mechanism 4 has a plurality of clamping sleeves 5.1, 5.2 and 5.3 arranged successively on the circumference of the drive shaft 1. Between the clamping sleeves 5.1 and 5.2 and between the clamping sleeves 5.2 and 5.3 are respectively arranged tensioning rings 6.1 and 6.2. The tensioning rings 6.1 and 6.2 protrude with tensioning flanges 17 between the clamping sleeves 5.1, 5.2 and 5.3.

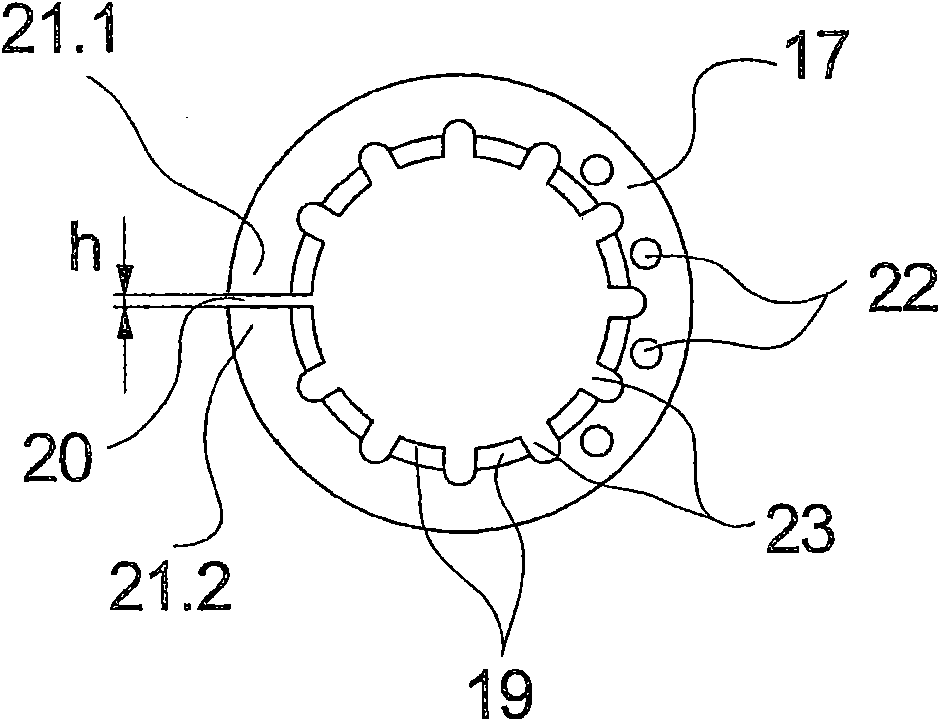

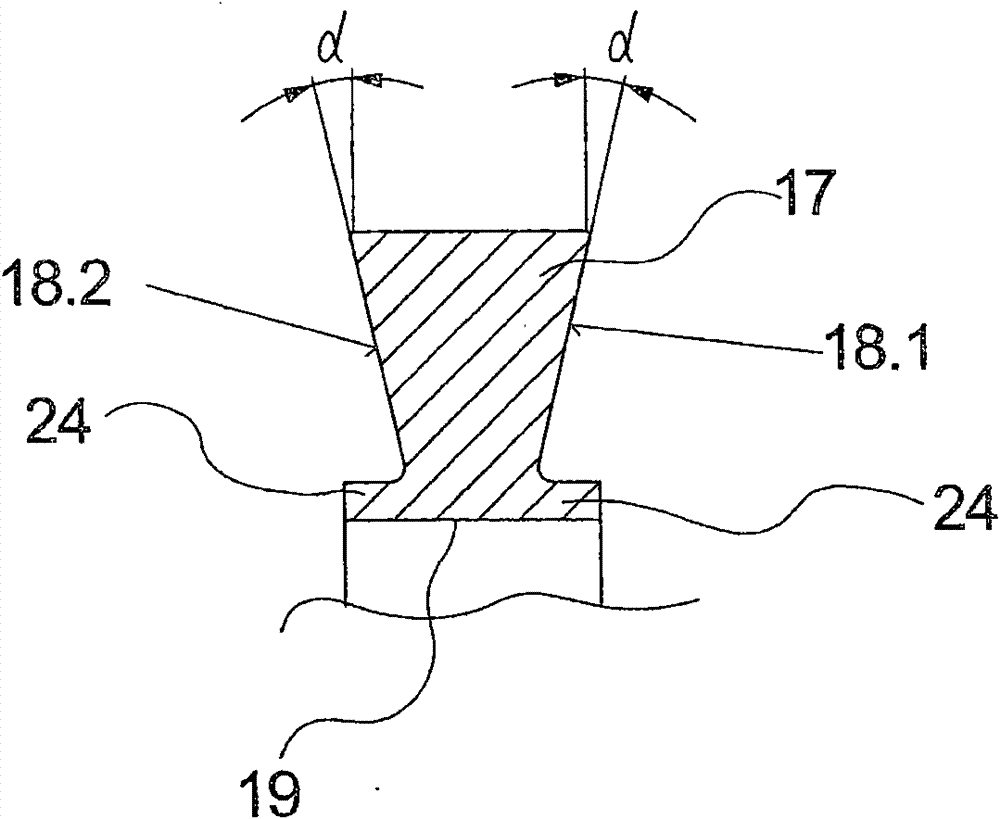

[0027] To illustrate tensioning rings 6.1 and 6.2, first refer to figure 2 and 3 , one of the tensioning rings 6.1 is schematically shown in several vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com