Double-layer PE large-scale hollow blow molding barrel and production process thereof

A production process, double-layer technology, applied in the field of plastic products production, can solve the problems of fragile products, defects in the molecular orientation of plastic molecules, and poor environmental protection in use, and achieve the effects of improving durability, sufficient orientation, and reducing use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

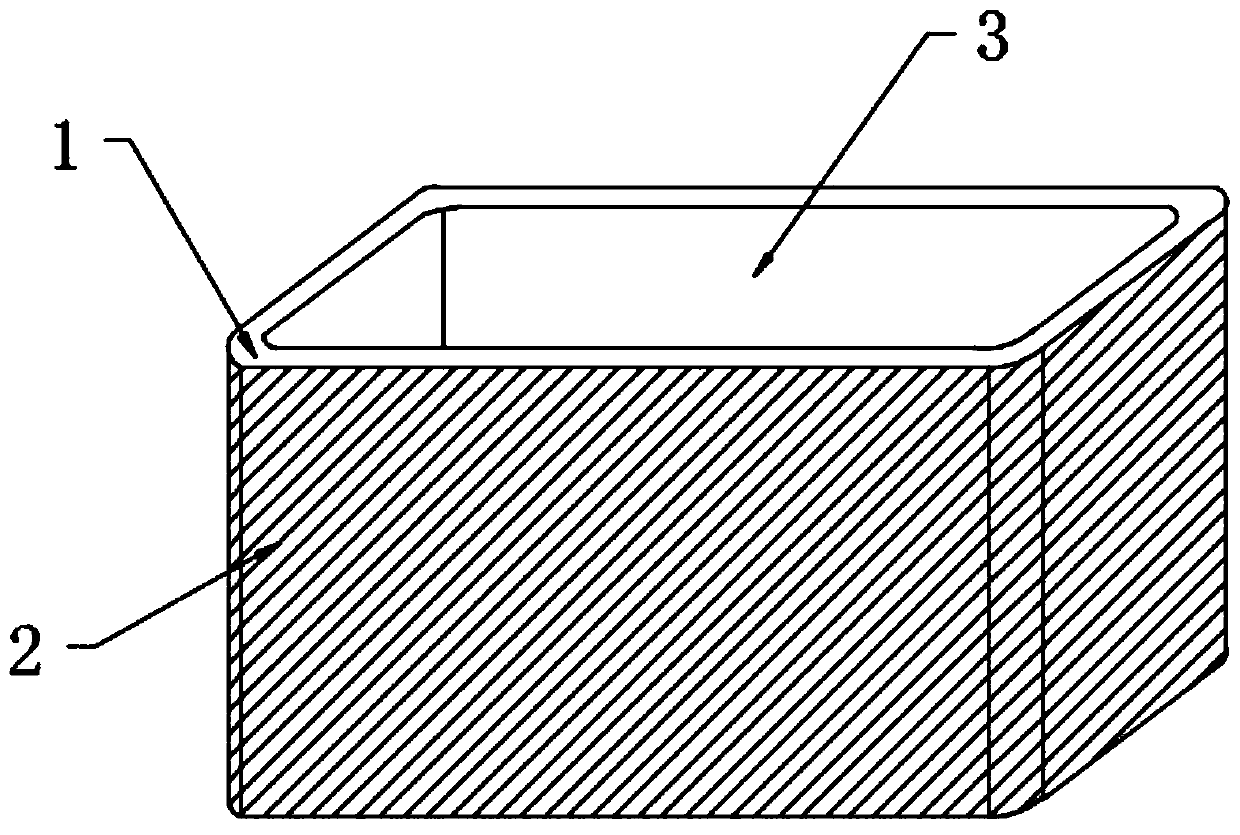

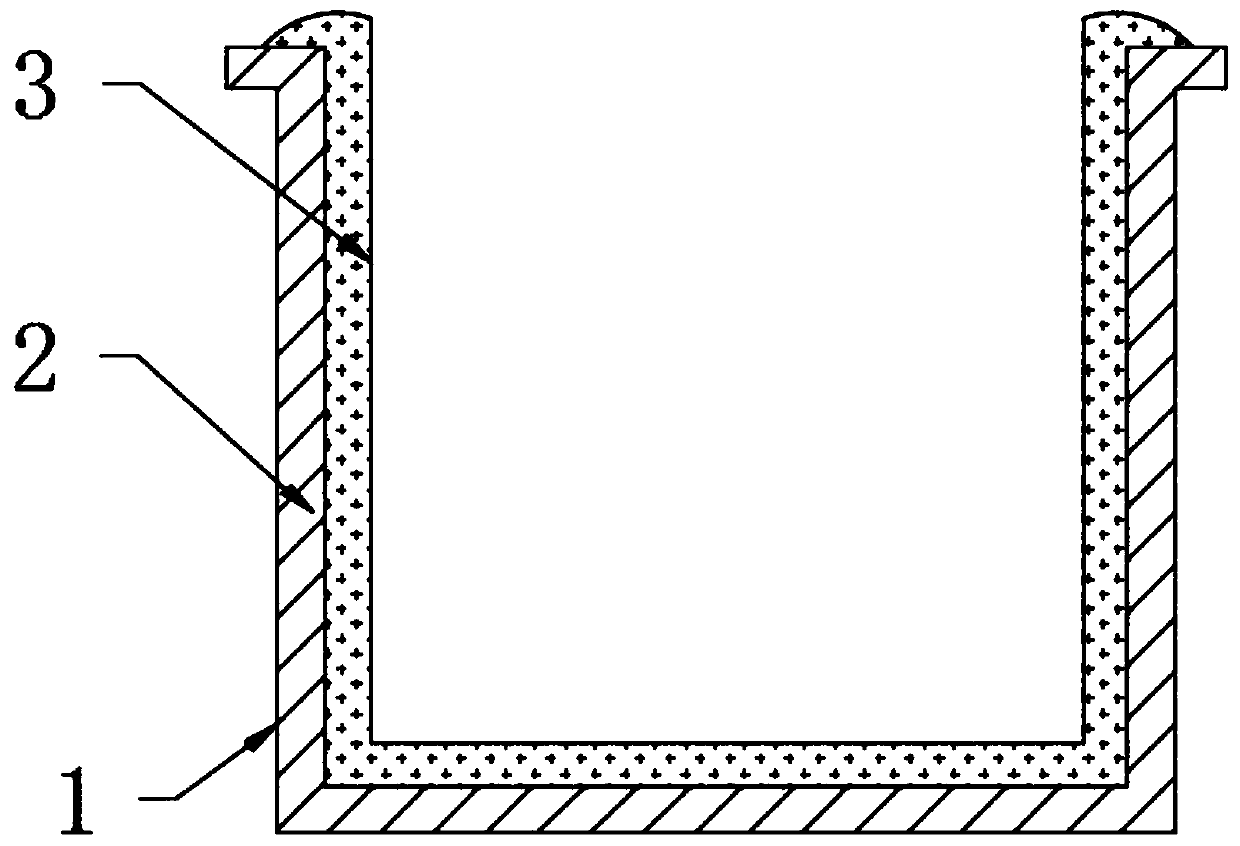

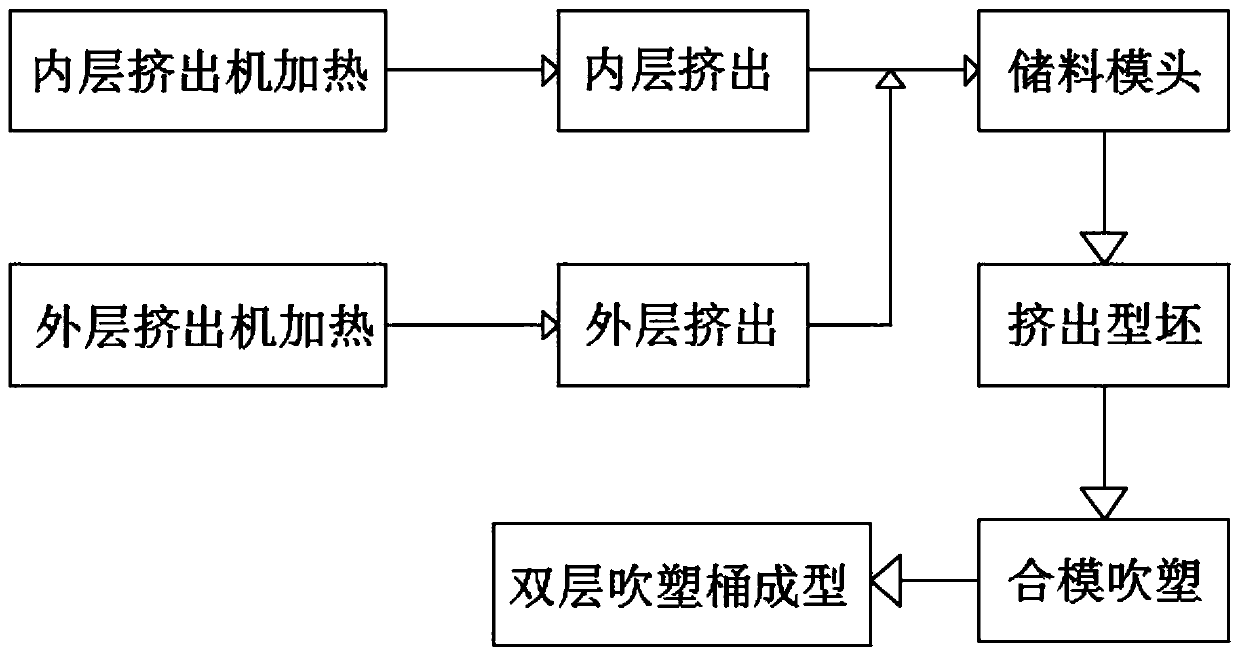

[0023] Such as Figure 1-3 As shown, the present invention provides a technical solution: a double-layer PE large-scale hollow blow molding barrel, including a blow molding barrel body 1, and the blow molding barrel body 1 includes an outer coloring layer 2 and an inner raw material natural color layer 3, and the inner material The raw material natural color layer 3 is located inside the outer colored layer 2, and the outer colored layer 2 and the inner raw material natural color layer 3 form a double-layer parison in the storage die head, and the outer colored layer 2 and the inner raw material natural color layer 3 are formed in the extrusion die. The inside of the head is connected into one body by extrusion and hot-melt, the outer colored layer 2 and the inner material nat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com