Method and apparatus for forming of radiation orientating round ring-shaped magnetic body

A technology of radiation orientation and forming method, applied in the manufacture of permanent magnets, inductors/transformers/magnets, electrical components, etc., can solve the problems of low degree of orientation, high degree of orientation, uneven degree of orientation, etc., and achieve the effect of complete orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

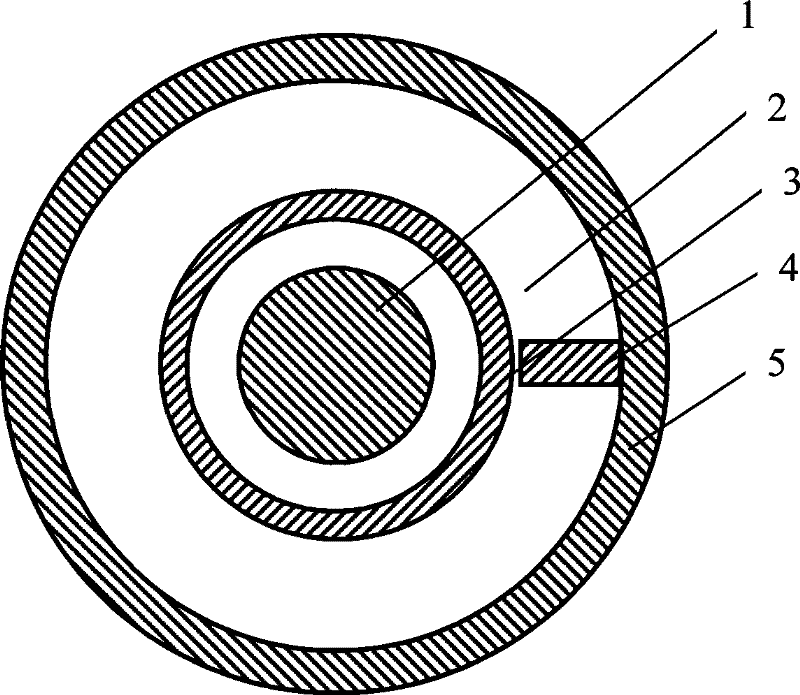

[0020] Embodiment 1: Make a radiation ring with an inner magnetic pole-outer magnetic pole orientation magnetic field.

[0021] Such as figure 1 As shown, when the two poles (N pole and S pole) of the magnetic field generated by the electromagnet or permanent magnet are respectively introduced into the inner magnetic pole 1 and the outer magnetic pole 5 through a certain magnetic conduction device, the inner magnetic pole 1 and the outer magnetic pole gathering head will be 4 to form a strong magnetic field. If the cavity 2 is filled with magnetic powder at this time, the magnetic powder in the magnetic field will be fully magnetized and oriented. If the outer magnetic pole gathering head 4 is fixed on the outer magnetic pole 5, the magnetization and radiation orientation of all the magnetic powder in the mold cavity 2 can be realized by driving the outer magnetic pole 5 to rotate at a high speed. While magnetizing and orienting the magnetic powder in the mold cavity 2, acco...

Embodiment 2

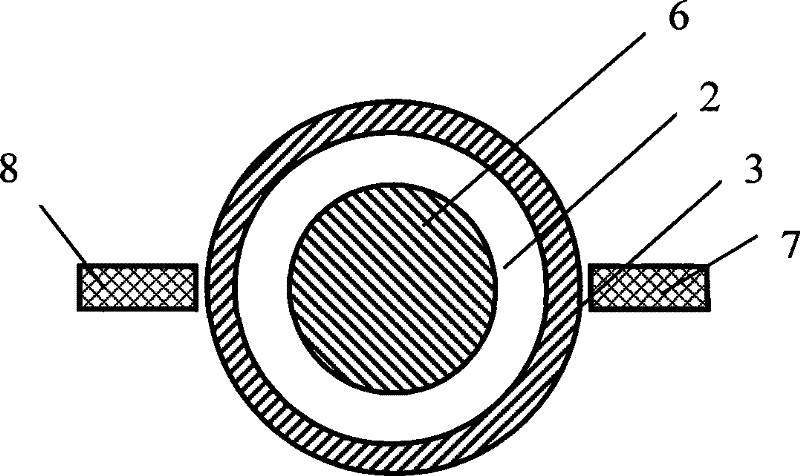

[0022] Embodiment 2: Make radiation ring with outer magnetic pole-outer magnetic pole type orientation magnetic field

[0023] Such as figure 2 As shown, when the two poles (N pole and S pole) of the magnetic field produced by the electromagnet or the permanent magnet are respectively introduced into the first outer magnetic pole 7 and the second outer magnetic pole 8 through a certain magnetic conduction device, it will be in the magnetic permeable core 6 Two strong magnetic fields are simultaneously formed between the first outer magnetic pole 7 and between the magnetic permeable core 6 and the second outer magnetic pole 8 . If the cavity 2 is filled with magnetic powder at this time, the magnetic powder in the two magnetic fields will be fully magnetized and oriented. The magnetization and orientation of all the magnetic powder in the mold cavity 2 can be realized by driving the first outer magnetic pole 7 and the second outer magnetic pole 8 to rotate at high speed at th...

Embodiment 3

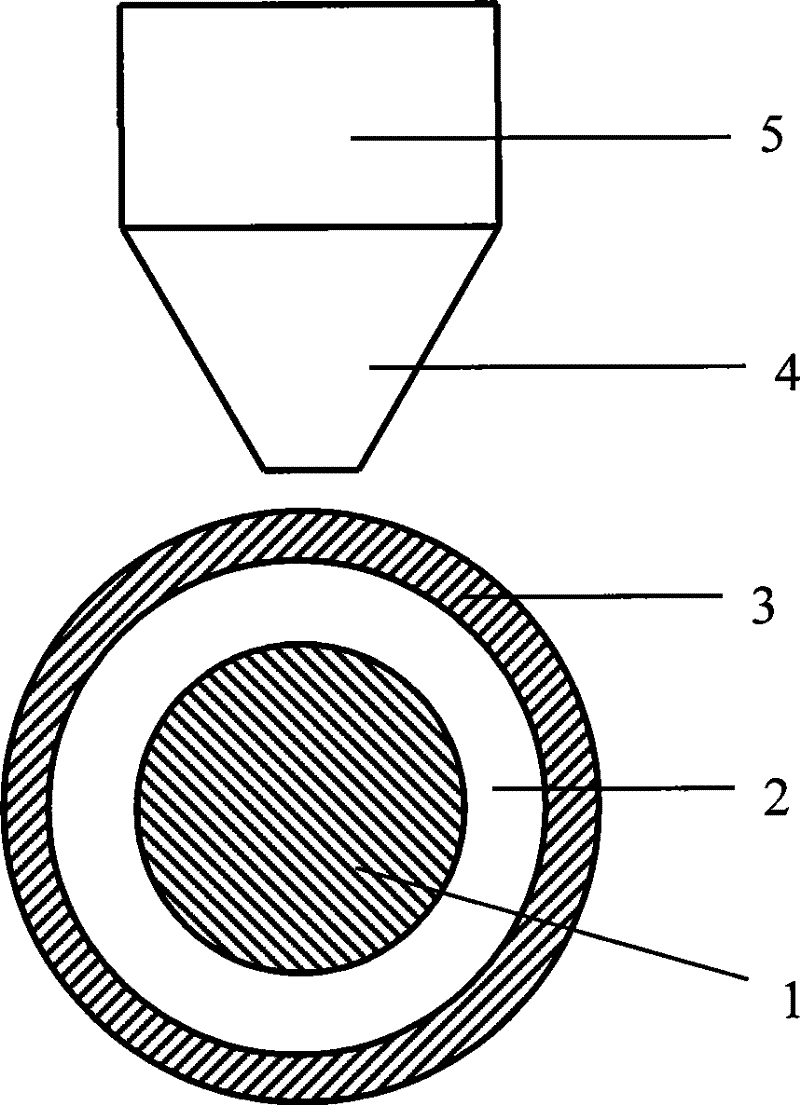

[0024] Embodiment 3: Another method of making a radiation ring with an inner magnetic pole-outer magnetic pole type orientation magnetic field

[0025] Such as image 3As shown, when the two poles (N pole and S pole) of the magnetic field generated by the electromagnet or permanent magnet are respectively introduced into the inner magnetic pole 1 and the outer magnetic pole 5 through a certain magnetic conduction device, the inner magnetic pole 1 and the outer magnetic pole gathering head will be 4 to form a strong magnetic field. If the cavity 2 is filled with magnetic powder at this time, the magnetic powder in the magnetic field will be fully magnetized and oriented. If (1) the magnetic powder in the non-magnetic mold 3 and the mold cavity 2 and the inner magnetic pole 1 are fixed on the frame of the molding equipment and relatively stationary, the outer magnetic pole 5 and the magnetic head 4 are connected to the rotary drive mechanism to surround the non-magnetic mold 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com