Diphenyl liquid-crystal epoxy resin as well as preparation method and application thereof

An epoxy resin and biphenyl technology, applied in liquid crystal materials, chemical instruments and methods, organic chemistry, etc., can solve the problems of high melting point, high cost, difficult curing process, etc., to improve thermal conductivity, reduce scattering, curing low difficulty effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048]A preparation method of 4,4'-bis(5,6-epoxyhexyloxy) biphenyl liquid crystal epoxy resin, comprising the following steps:

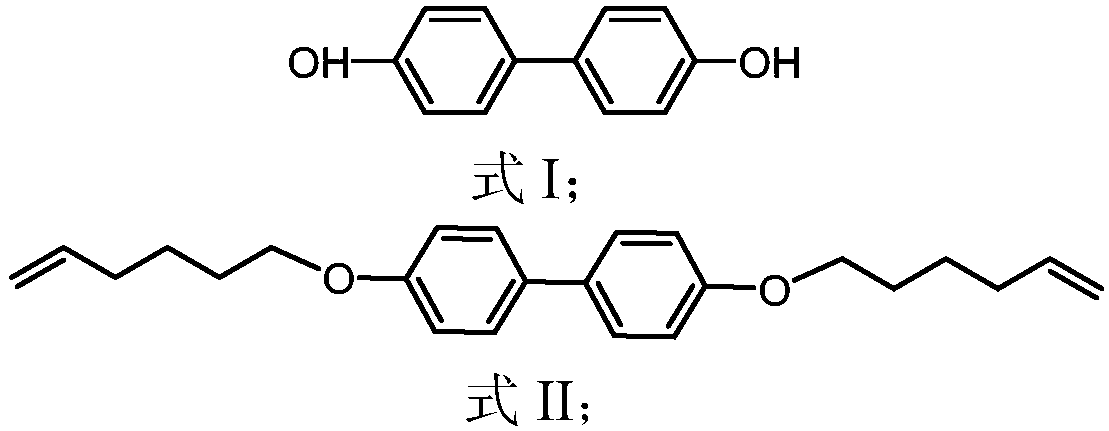

[0049] (1) Dissolve 18.6g of biphenol shown in formula I in 350-500mL of acetone under the protection of nitrogen, raise the temperature to 60°C, add 34.5g of anhydrous potassium carbonate powder, and stir for half an hour to one hour , Add 40.75g of 6-bromo-1-hexene in batches, and react for 24h. Potassium carbonate was removed by filtration, the filtrate was vacuum-distilled to remove acetone, washed several times with absolute ethanol, filtered to obtain white flaky crystals, and dried in vacuum at 50°C to obtain 4,4'-bis(5-hexenyloxy) as shown in II. Base) biphenyl, productive rate 84%;

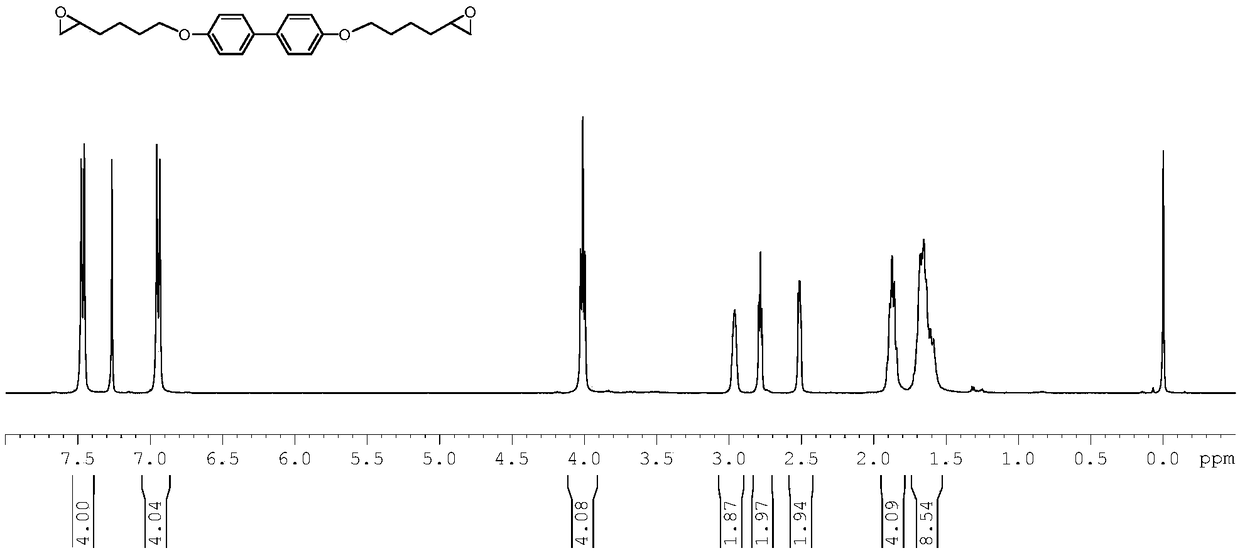

[0050] (2) Dissolve 14g of 4,4'-bis(5-hexenyloxy)biphenyl prepared in step (1) in 150-200mL of dichloromethane, raise the temperature to 40°C, and add 17.2g of m-chloro Peroxybenzoic acid, reacted for 1 week, filtered to remove the precipitated m-chlorobenzoic...

Embodiment 2

[0053] A preparation method of 4,4'-bis(5,6-epoxyhexyloxy) biphenyl liquid crystal epoxy resin, comprising the following steps:

[0054] (1) Dissolve 18.6g of biphenol shown in formula I in 350-500mL of acetone under the protection of nitrogen, raise the temperature to 60°C, add 34.5g of anhydrous potassium carbonate powder, and stir for half an hour to one hour , Add 40.75g of 6-bromo-1-hexene in batches, and react for 24h. Potassium carbonate was removed by filtration, the filtrate was vacuum-distilled to remove acetone, washed several times with absolute ethanol, filtered to obtain white flaky crystals, and dried in vacuum at 50°C to obtain 4,4'-bis(5-hexenyloxy) as shown in II. Base) biphenyl, productive rate 84%;

[0055] (2) Dissolve 14g of 4,4'-bis(5-hexenyloxy)biphenyl prepared in step (1) in 150-200mL of dichloromethane, raise the temperature to 40°C, and add 17.2g of m-chloro Peroxybenzoic acid, reacted for 1 week, filtered to remove the precipitated m-chlorobenzoi...

Embodiment 3

[0058] A preparation method of 4,4'-bis(5,6-epoxyhexyloxy) biphenyl liquid crystal epoxy resin, comprising the following steps:

[0059] (1) Dissolve 18.6g of biphenol shown in formula I in 350-500mL of acetone under the protection of nitrogen, raise the temperature to 60°C, add 34.5g of anhydrous potassium carbonate powder, and stir for half an hour to one hour , Added 35.86g of 6-bromo-1-hexene in batches, and reacted for 24h. Potassium carbonate was removed by filtration, the filtrate was vacuum-distilled to remove acetone, washed several times with absolute ethanol, filtered to obtain white flaky crystals, and dried in vacuum at 50°C to obtain 4,4'-bis(5-hexenyloxy) as shown in II. Base) biphenyl, productive rate 80%;

[0060] (2) Dissolve 14g of 4,4'-bis(5-hexenyloxy)biphenyl prepared in step (1) in 150-200mL of dichloromethane, raise the temperature to 40°C, and add 15.14g of m-chloro Peroxybenzoic acid, reacted for 1 week, filtered to remove the precipitated m-chlorob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com