High-water-content dredged sludge curing agent as well as preparation method and application thereof

A technology for dredging sludge and high water content, applied in chemical instruments and methods, water/sludge/sewage treatment, fixed/solidified sludge treatment, etc. , to achieve the effect of saving landfill land, reducing curing costs and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

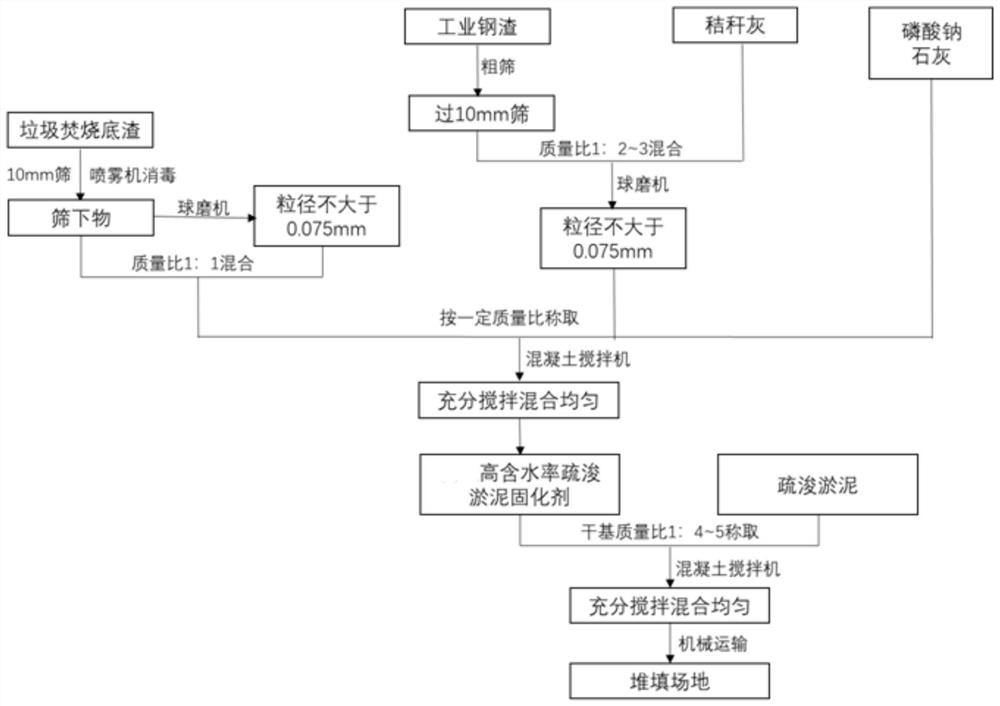

Image

Examples

Embodiment 1

[0039] In this example, a high water content dredging sludge curing agent is prepared, which is used to treat dredging sludge with a water content of 60%.

[0040] The high water content dredging sludge curing agent includes the following raw materials in mass percentage: 28% industrial steel slag, 42% waste incineration bottom slag mixture, 6% sodium phosphate, 14% straw ash, and 10% lime.

[0041] The preparation and application method of described high water content dredging sludge curing agent comprises the following steps:

[0042] (1) Preliminarily screen waste incineration bottom slag and industrial steel slag through a 10mm sieve to remove large particles, obtain waste incineration bottom slag and industrial steel slag underscreen, and screen waste incineration bottom slag The lower objects are disinfected by spraying disinfectant with a sprayer;

[0043] (2) Add part of the sieved waste incineration bottom slag to the ball mill for ball milling to obtain a fine powde...

Embodiment 2

[0049] In this example, a high water content dredging sludge curing agent is prepared, which is used to treat dredging sludge with a water content of 70%.

[0050] The high water content dredging sludge solidifying agent includes the following raw materials in mass percentage: 30% industrial steel slag, 40% waste incineration bottom slag mixture, 5% sodium phosphate, 14% straw ash, and 11% lime.

[0051] The preparation and application method of described high water content dredging sludge curing agent comprises the following steps:

[0052] (1) Preliminarily screen waste incineration bottom slag and industrial steel slag through a 10mm sieve to remove large particles, obtain waste incineration bottom slag and industrial steel slag underscreen, and screen waste incineration bottom slag The lower objects are disinfected by spraying disinfectant with a sprayer;

[0053] (2) Add part of the sieved waste incineration bottom slag to the ball mill for ball milling to obtain a fine ...

Embodiment 3

[0058] In this example, a high water content dredging sludge curing agent is prepared, which is used to treat dredging sludge with a water content of 80%.

[0059] The high water content dredging sludge curing agent includes the following raw materials in mass percentage: 35% industrial steel slag, 36% waste incineration bottom slag mixture, 4% sodium phosphate, 13% straw ash, and 12% lime.

[0060] The preparation and application method of described high water content dredging sludge curing agent comprises the following steps:

[0061] (1) Preliminarily screen waste incineration bottom slag and industrial steel slag through a 10mm sieve to remove large particles, obtain waste incineration bottom slag and industrial steel slag underscreen, and screen waste incineration bottom slag The lower objects are disinfected by spraying disinfectant with a sprayer;

[0062] (2) Add part of the sieved waste incineration bottom slag to the ball mill for ball milling to obtain a fine powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com