A kind of liquid crystal epoxy resin and its preparation method and application

An epoxy resin and liquid crystal technology, applied in the direction of organic chemistry, can solve the problems of high curing process cost and high melting point, and achieve the effect of low curing cost, high curing temperature and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

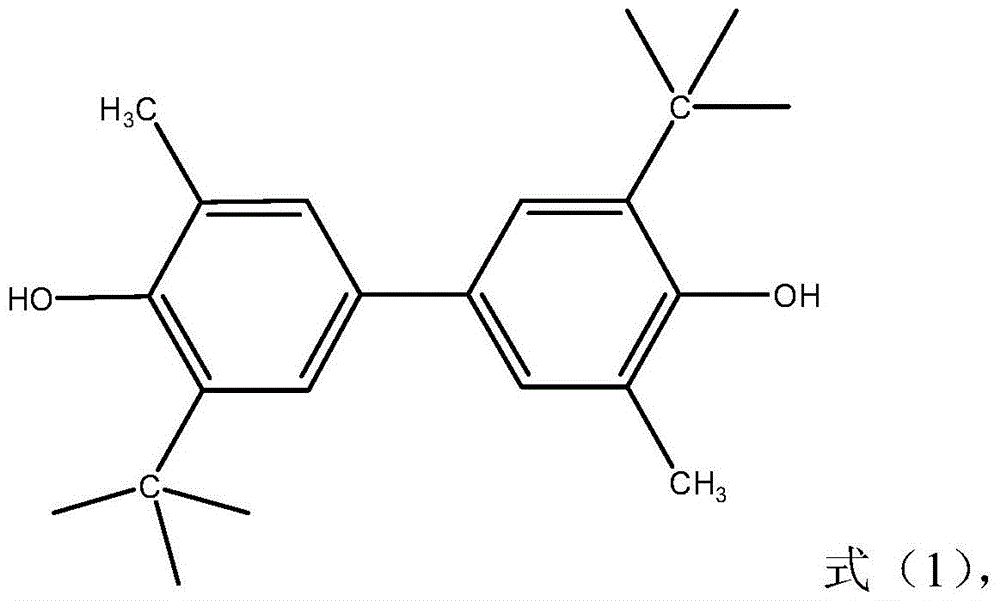

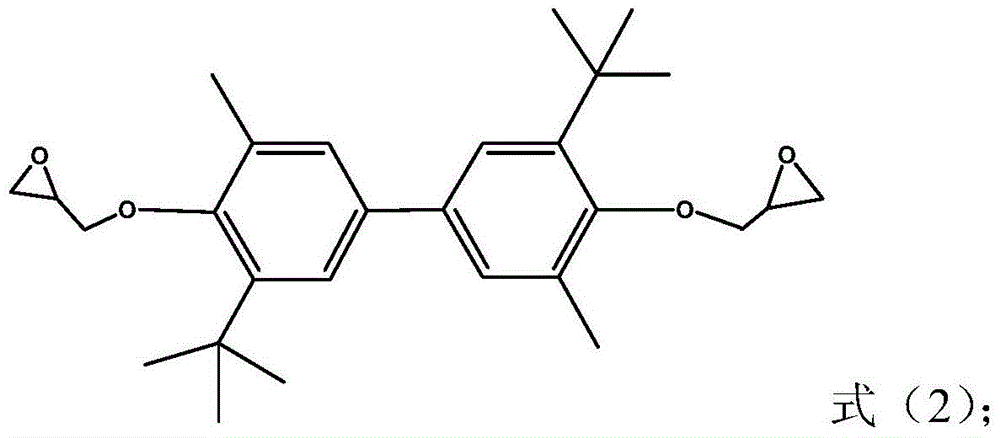

[0030] A preparation method of 3,5'-di-tert-butyl-5,3'-dimethyl biphenyl diglycidyl ether liquid crystal epoxy resin, comprising the following steps:

[0031] (1) Dissolve 32g of 3,5'-di-tert-butyl-5,3'-dimethylbiquinone shown in general formula (1) in 130g of epichlorohydrin and 80mL of In isopropanol, heat up to 70°C, add 0.96g tetrabutylammonium bromide, after the system is clear and transparent, slowly add (10min) 40g aqueous sodium hydroxide solution with a mass fraction of 30%, react for 3h, vacuumize and distill to remove Excess epichlorohydrin and isopropanol, the product was extracted with the organic solvent ethyl acetate, washed several times with water, dried with anhydrous sodium sulfate to remove water, filtered to obtain the filtrate, and the organic solvent ethyl acetate was removed by rotary evaporation, vacuum at 50°C Dry to obtain 3,5'-di-tert-butyl-5,3'-dimethylbiphenyl diglycidyl ether represented by formula (2), with a yield of 94%;

[0032] (2) Mix 5.27...

Embodiment 2

[0034] A preparation method of 3,5'-di-tert-butyl-5,3'-dimethyl biphenyl diglycidyl ether liquid crystal epoxy resin, comprising the following steps:

[0035] (1) Dissolve 32g of 3,5'-di-tert-butyl-5,3'-dimethylbiquinone shown in general formula (1) in 130g of epichlorohydrin and 80mL of In isopropanol, heat up to 80°C, add 1g of benzyltriethylammonium chloride, after the system is clear and transparent, slowly add (9min) 40g of 40% aqueous sodium hydroxide solution dropwise, react for 2h, vacuum distillation Remove excess epichlorohydrin and isopropanol, extract the product with organic solvent dichloromethane, wash with water several times, dry with desiccant anhydrous magnesium sulfate to remove water, filter to obtain filtrate, rotary evaporate to remove organic solvent dichloromethane, 50°C Vacuum drying to obtain 3,5'-di-tert-butyl-5,3'-dimethylbiphenyl diglycidyl ether represented by formula (2), with a yield of 92%;

[0036] (2) Mix 5.27g of 3,5'-di-tert-butyl-5,3'-di...

Embodiment 3

[0038] A preparation method of 3,5'-di-tert-butyl-5,3'-dimethyl biphenyl diglycidyl ether liquid crystal epoxy resin, comprising the following steps:

[0039] (1) Dissolve 32g of 3,5'-di-tert-butyl-5,3'-dimethylbiquinone shown in general formula (1) in 130g of epichlorohydrin and 80mL of In isopropanol, heat up to 70°C, add 0.96g tetrabutylammonium bromide, after the system is clear and transparent, slowly add (8min) 40g aqueous sodium hydroxide solution with a mass fraction of 30%, react for 3h, vacuumize and distill off Excess epichlorohydrin and isopropanol, the product was extracted with the organic solvent ethyl acetate, washed several times with water, dried with anhydrous sodium sulfate to remove water, filtered to obtain the filtrate, and the organic solvent ethyl acetate was removed by rotary evaporation, vacuum at 50°C Dry to obtain 3,5'-di-tert-butyl-5,3'-dimethylbiphenyl diglycidyl ether shown in formula (2);

[0040] (2) 5.27g of 3,5'-di-tert-butyl-5,3'-dimethylb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com