Directional heat-conducting fin and preparation method thereof, and semiconductor heat dissipation device

A technology of directional thermal conductivity and thermal conductivity filler, applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve the problems of poor fluidity, difficult extrusion processing, uneven composition, etc. Has good orientation and orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

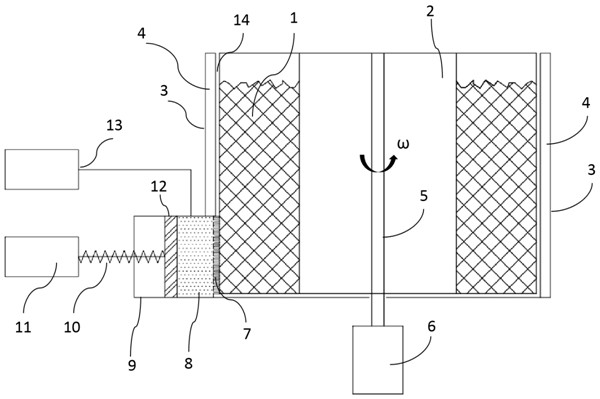

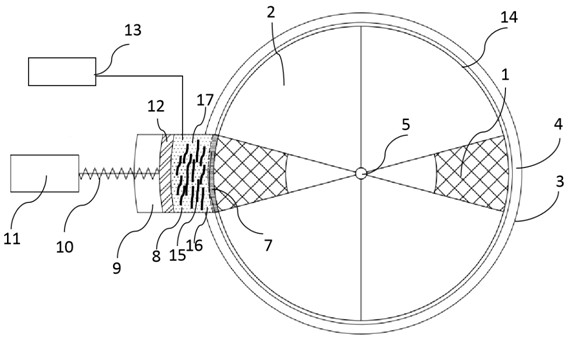

[0044] This embodiment provides an orientation forming device, see figure 1 and figure 2 , the orientation molding device includes:

[0045] Cylindrical drum 2, the central axis of the drum 2 is fixed with a rotating shaft 5, one end of the rotating shaft 5 is a motor one 6, and the motor one 6 drives the rotating drum 2 to rotate through the rotating shaft 5; Axisymmetric is the charging area 1, and the charging area 1 is two fan-shaped cylindrical areas, and the two fan-shaped cylindrical areas are arranged symmetrically with respect to the central axis of the drum. The bottom side of the drum 2 in the charging area 1 is provided with a drum opening;

[0046] A sleeve 3, the sleeve 3 is provided with an interlayer, and the interlayer is filled with a cooling medium 4. The sleeve 3 is sheathed outside the drum 2. In this embodiment, there is a gap 14 between the drum 2 and the sleeve 3, and the distance between the gaps 14 is 0.1-5mm. The drum 2 can rotate inside the sle...

Embodiment 2

[0052] This embodiment provides a method for preparing an oriented thermally conductive sheet, using an oriented forming device in Example 1, and the specific implementation steps are as follows:

[0053] S1. Ingredients: 100g of addition-type silicone oil (55g of vinyl silicone oil, 44.9g of hydrogen-containing silicone oil and 0.1g of platinum catalyst), 75g of carbon fiber powder (0.1mm in length, 15μm in diameter) and 300g of spherical alumina, mix and stir 30min, vacuum defoaming for 5min to form a fluid composition with a viscosity of 200,000 mPa·s;

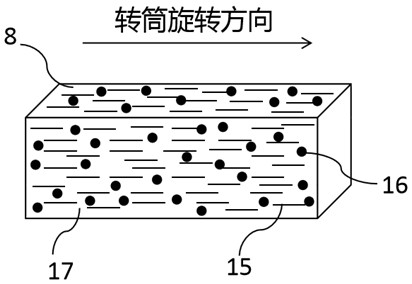

[0054] S2. Orientation molding: the fluid composition obtained in step S1 is placed in the symmetrical charging area of the drum of the orientation molding device, and the angular velocity of the drum is set to 70r / min for circular motion. During the circular motion, the composition is subjected to the effect of centrifugal force Enter the gap between the drum and the sleeve from the opening at the bottom of the drum, the...

Embodiment 3

[0059] This embodiment provides a method for preparing an oriented thermally conductive sheet, using an oriented forming device in Example 1, and the specific implementation steps are as follows:

[0060] S1. Ingredients: 100g reactive silicone oil (a mixture of 55g vinyl silicone oil, 44.9g hydrogen-containing silicone oil and 0.1g platinum catalyst), 120g carbon fiber powder (0.1mm in length, 15μm in diameter), 300g spherical alumina and 50g spherical Aluminum nitride, mixed and stirred for 30 minutes, vacuum degassed for 5 minutes to form a fluid composition with a viscosity of 650,000 mPa s;

[0061] S2. Orientation molding: the fluid composition obtained in step S1 is placed in the symmetrical charging area of the drum of the orientation molding device, and the angular velocity of the drum is set to 90r / min for circular motion. During the circular motion, the composition is subjected to the effect of centrifugal force Enter the gap between the drum and the sleeve from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com