A progressive orientation mold for a multi-pole magnetic ring and its orientation method

A multi-pole magnetic ring, progressive technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of surface magnetic tool difference, large upper and lower pole difference, etc., to achieve consistent performance, convenient control and management , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

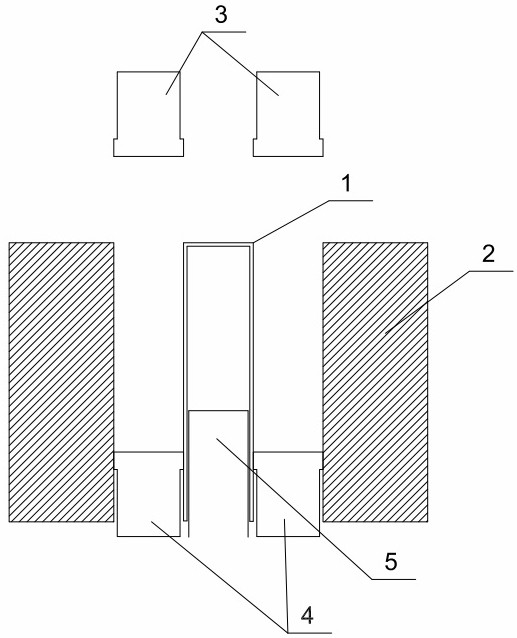

[0029] as Figure 1- Figure 2 As shown, the orientation step is a continuous process, Figure 1-2 It is only a screenshot of some representative orientation steps, and the specific orientation steps are described later.

[0030] 1.1 Orientation mold

[0031] Example 1 provides a multipolar magnetic ring progressive orientation die, comprising a die core 1 and a die sleeve 2 disposed on the outside of the die core 1, the die 1 has a toroidal gap between the die 1 and the die sleeve 2;

[0032] The die core 1 is provided with a cavity, the cavity is provided with a movable aligner 5, the aligner 5 and the controller is connected;

[0033] The upper end of the annular void is provided with a size matching upper indenter 3, the lower end of the annular void is provided with a size matching lower indenter 4, the outer wall of the die core 1, the inner wall of the mold sleeve 2, the lower surface of the upper indenter 3 and the upper surface of the lower indenter 4 form a mold cavity.

[00...

Embodiment 2

[0043] 2.1 Orientation mold

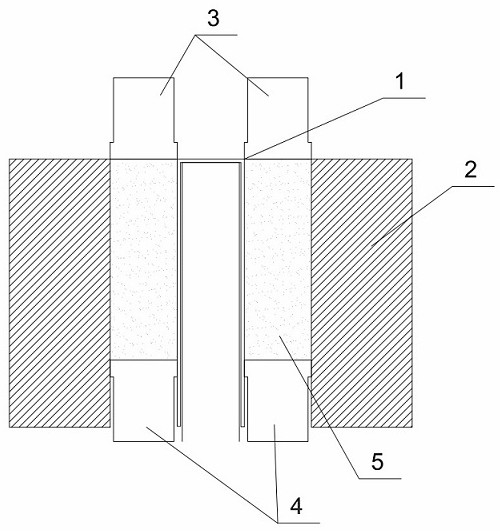

[0044] as Figure 3 as shown,

[0045] Example 2 provides a multipolar magnetic ring progressive orientation die, comprising a die core 1 and a die sleeve 2 disposed on the outside of the die core 1, the die 1 has a toroidal gap between the die 1 and the die sleeve 2;

[0046] The module sleeve 2 is provided with a cavity, the cavity is provided with a movable aligner 5, the aligner 5 and the controller connection;

[0047] The upper end of the annular void is provided with a size matching upper indenter 3, the lower end of the annular void is provided with a size matching lower indenter 4, the outer wall of the die core 1, the inner wall of the mold sleeve 2, the lower surface of the upper indenter 3 and the upper surface of the lower indenter 4 form a mold cavity.

[0048] As an alternative embodiment, the controller is a PLC controller.

[0049] As an alternative embodiment, the aligner 5 is a multipolar magnetic ring special aligner, the number of ...

Embodiment 3

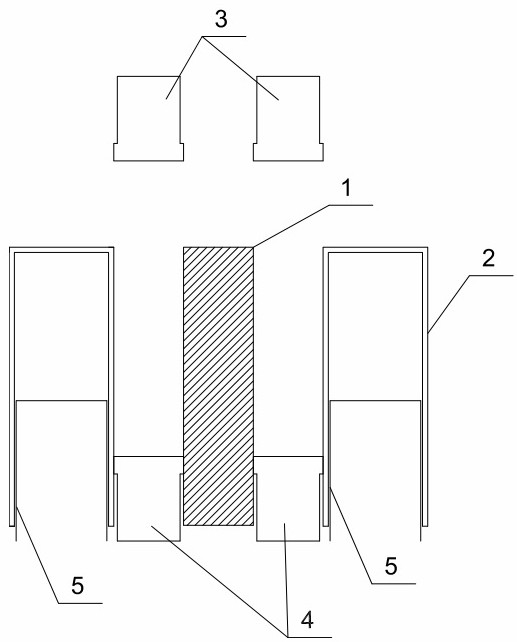

[0057] 3.1 Orientation mold

[0058] Example 3 provides a multipolar magnetic ring progressive orientation die, comprising a die core 1 and a die sleeve 2 disposed on the outside of the die core 1, the die 1 has a toroidal gap between the die 1 and the die sleeve 2;

[0059] The die core 1 and the die sleeve 2 are equipped with a cavity, the cavity is provided with a movable aligner 5, the oriented device 5 and the controller is connected;

[0060] The upper end of the annular void is provided with a size matching upper indenter 3, the lower end of the annular void is provided with a size matching lower indenter 4, the outer wall of the die core 1, the inner wall of the mold sleeve 2, the lower surface of the upper indenter 3 and the upper surface of the lower indenter 4 form a mold cavity.

[0061] As an alternative embodiment, the controller is a PLC controller.

[0062] As an alternative embodiment, the aligner 5 is a multipolar magnetic ring special oriented device, the number...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com