A kind of preparation method of rare earth permanent magnet with high homogeneity and high performance

A rare earth permanent magnet and homogeneity technology, which is applied in the direction of inductance/transformer/magnet manufacturing, magnetic objects, magnetic materials, etc., can solve the problems of difficult uniform mixing of particle size, influence on the distribution of magnetic force lines, and poor homogeneity of magnets, etc., to achieve The effects of eliminating the bending of the orientation magnetic force line, improving the magnetic difference of the NS pole surface, and preventing the distribution of the magnetic force line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

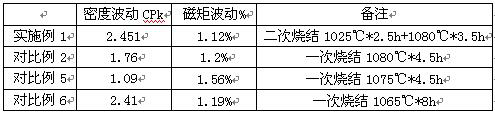

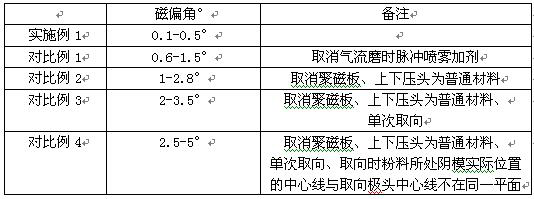

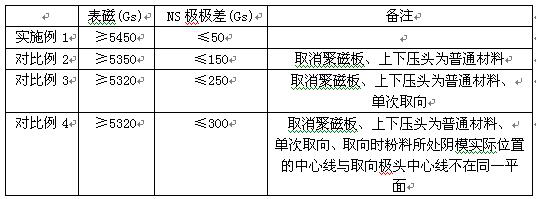

Examples

Embodiment 1

[0033] A method for preparing a high-homogeneity and high-performance rare earth permanent magnet, comprising the following steps:

[0034] 1) The industrial pure metal raw materials are weighed and proportioned according to the composition of the NdFeB alloy by weight percentage, and the composition mass percentage of the NdFeB alloy is (PrNd 1-x RE x ) a Fe bal Al b Cu c m d co e B f , where a=30%; where RE uses Ho element, x=0.05; b=0.4%; c=0.2%; e=1%, f=0.92%; where d=0.3%, M is Ti element 0.18% , Ga element 0.12%; the target raw material is vacuum smelted, and then quickly quenched into an alloy cast sheet;

[0035] 2) The alloy cast piece obtained in step 1) is not directly crushed by hydrogen, but exposed to the air first, and freely absorbs oxygen for 10-30 days, so that the neodymium-rich phase of the alloy cast piece can fully absorb oxygen;

[0036] 3) The alloy cast in step 2) after the neodymium-rich phase has fully absorbed oxygen is subjected to hydroge...

Embodiment 2

[0070] 1) The industrial pure metal raw materials are weighed and proportioned according to the composition of the NdFeB alloy by weight percentage, and the composition mass percentage of the NdFeB alloy is (PrNd 1-x RE x ) a Fe bal Al b Cu c m d co e B f , where a=30%; where RE uses Ho element, x=0.05; b=0.4%; c=0.2%; e=1%, f=0.92%; where d=0.3%, M is Ti element 0.18% , Ga element 0.12%; the target raw material is vacuum smelted, and then quickly quenched into an alloy cast sheet;

[0071] 2) The alloy cast piece obtained in step 1) is not directly crushed by hydrogen, but exposed to the air first, and freely absorbs oxygen for 10-30 days, so that the neodymium-rich phase of the alloy cast piece can fully absorb oxygen;

[0072] 3) The alloy cast in step 2) after the neodymium-rich phase has fully absorbed oxygen is subjected to hydrogen crushing for 2-4 hours, and then dehydrogenated for 4-8 hours;

[0073] 4) Cool the dehydrogenated alloy in step 3) to 35°C, stop c...

Embodiment 3

[0082] 1) The industrial pure metal raw materials are weighed and proportioned according to the composition of the NdFeB alloy by weight percentage, and the composition mass percentage of the NdFeB alloy is (PrNd 1-x RE x ) a Fe bal Al b Cu c m d co e B f , where a=30%; where RE uses Ho element, x=0.05; b=0.4%; c=0.2%; e=1%, f=0.92%; where d=0.3%, M is Ti element 0.18% , Ga element 0.12%; the target raw material is vacuum smelted, and then quickly quenched into an alloy cast sheet;

[0083] 2) The alloy cast piece obtained in step 1) is not directly crushed by hydrogen, but exposed to the air first, and freely absorbs oxygen for 10-30 days, so that the neodymium-rich phase of the alloy cast piece can fully absorb oxygen;

[0084] 3) The alloy cast in step 2) after the neodymium-rich phase has fully absorbed oxygen is subjected to hydrogen crushing for 2-4 hours, and then dehydrogenated for 4-8 hours;

[0085] 4) Cool the dehydrogenated alloy in step 3) to 35°C, stop c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com