High-tensile-strength polyester film for lithium battery current collector and preparation method thereof

A high tensile strength, polyester film technology, applied in the field of polyester film, can solve the problems of reduced mechanical strength, reduced processing performance, reduced thickness of aluminum foil, etc., to achieve increased strength, improved orientation and crystallinity, and small heat shrinkage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A preparation method of a high tensile strength polyester film for a lithium battery current collector, comprising the following steps:

[0041] S1 raw material preparation ratio: prepare the raw materials of the surface layer A and the raw materials of the core layer B;

[0042] S2 Extrusion Casting: Put the raw material of the surface layer A into the auxiliary extruder and melt it at 265-285°C, add the raw material of the core layer B into the main extruder and melt it at the temperature of 275-295°C, pass through the metering pump and filter It is transported to the distributor, and is divided into ABA three-layer structure co-extrusion through the distributor and the special die head. Composite casting on a cold drum at a temperature of 20°C;

[0043]S3 Synchronous Stretching Film Production: Afterwards, the composite cast sheets are sent to the synchronous stretching oven respectively, and the preheating temperature of the oven is 90-110°C, and then at the temper...

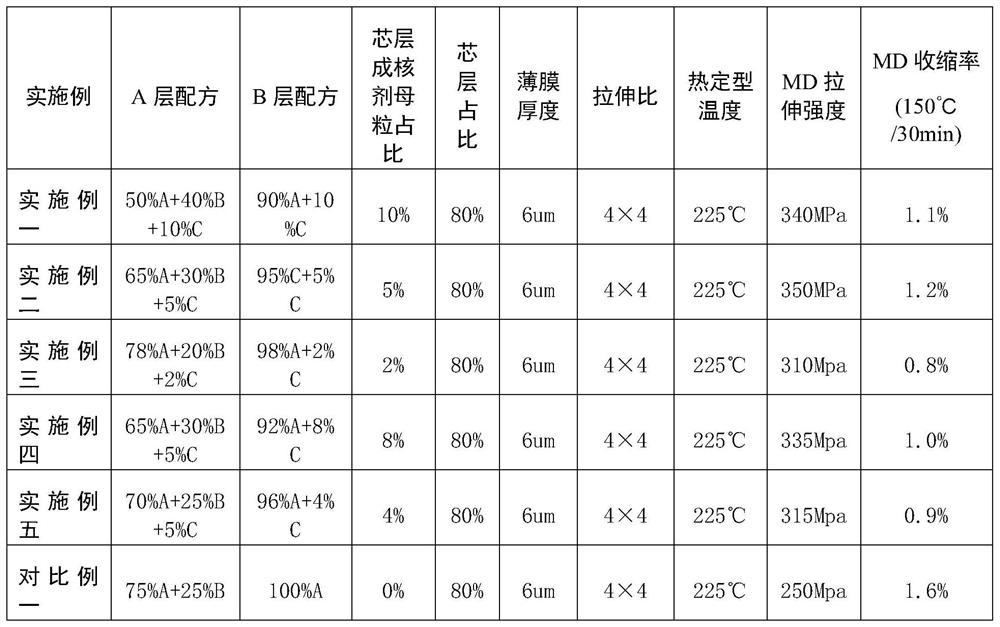

Embodiment 1

[0048] S1 material preparation ratio:

[0049] Surface layer A: The raw material composition of the surface layer A includes: 50% raw material A, 40% raw material B, 10% raw material C in terms of mass percentage;

[0050] Core layer B: The raw material composition of the core layer B includes: 90% raw material A, 10% raw material C in terms of mass percentage;

[0051] Wherein, raw material A is high-viscosity polyethylene terephthalate with an intrinsic viscosity of 0.75dl / g; it can be obtained commercially;

[0052] Raw material B contains nano-scale SiO 2 Additives for polyethylene terephthalate, SiO 2 The content is 3500ppm, and the intrinsic viscosity is 0.64dl / g; it can be obtained from the market;

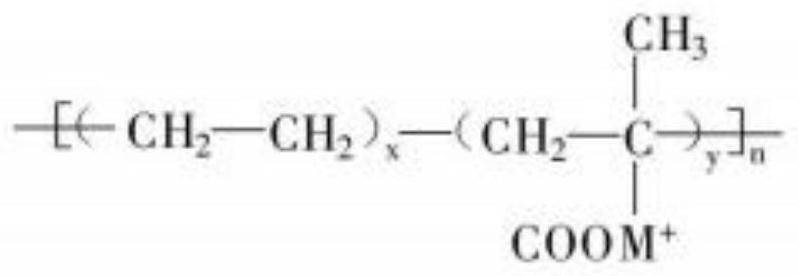

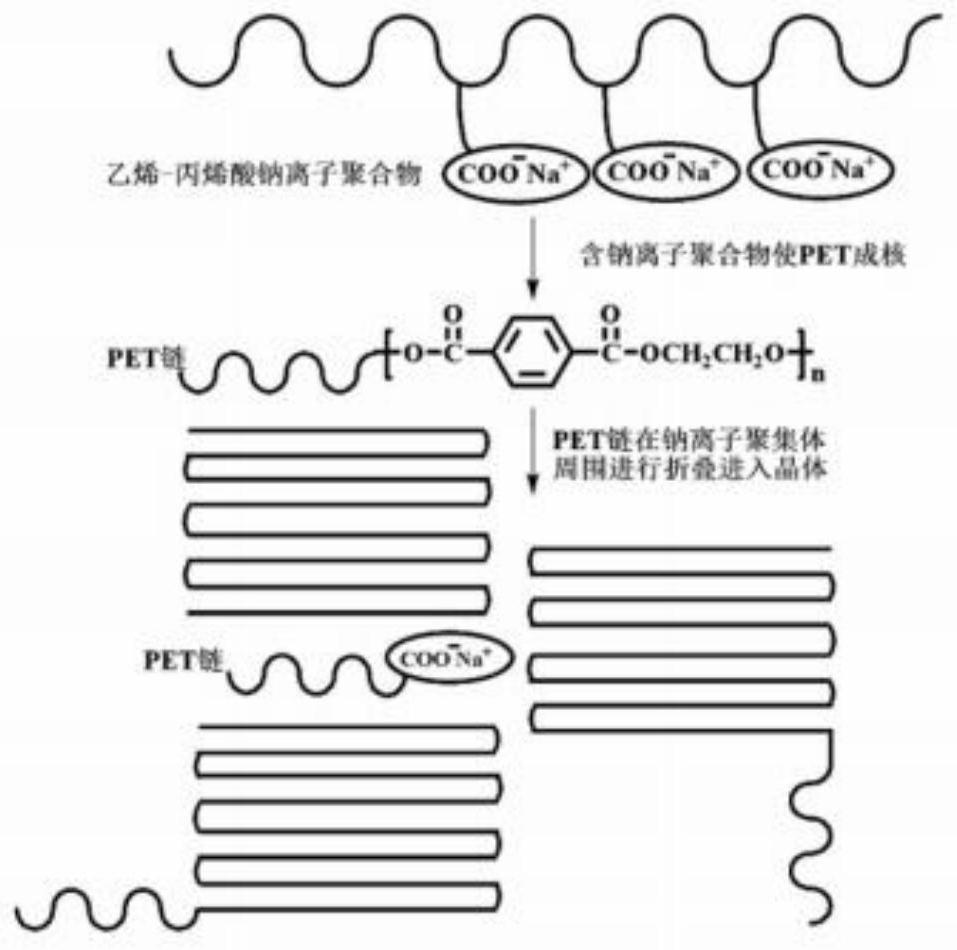

[0053] Raw material C is self-made high-viscosity polyethylene terephthalate containing 8% crystallization improver Surly8920;

[0054] Wherein, the mass ratio of the core layer B accounts for 80% of the total mass of the three-layer composite structure;

[0055] S2 Ex...

Embodiment 2

[0059] The preparation process is the same as that of Example 1, except that in the S1 preparation and proportioning process, the selection of raw material components is different;

[0060] S1 material preparation:

[0061] Surface layer A: The raw material composition of the surface layer A includes: 65% raw material A, 30% raw material B, 5% raw material C in terms of mass percentage;

[0062] Core layer B: The raw material composition of the core layer B includes: 95% raw material A, 5% raw material C in terms of mass percentage;

[0063] Wherein, raw material A is the high-viscosity polyethylene terephthalate that intrinsic viscosity is 0.75dl / g;

[0064] Raw material B contains nano-scale SiO 2 Additives for polyethylene terephthalate, SiO 2 The content is 3500ppm, and the intrinsic viscosity is 0.64dl / g;

[0065] Raw material C is self-made high-viscosity polyethylene terephthalate containing 8% crystallization improver Surly8920;

[0066] Among them, the mass of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com