Construction technology for foundation reinforcement of large-scale hydraulic structures in construction waste soil layer

A technology of foundation reinforcement and construction technology, applied in construction, earthwork drilling, soil protection, etc., can solve the problems of unsatisfactory foundation bearing capacity, single foundation reinforcement construction technology, high construction cost, etc., and achieve easy quality control, The effect of high construction efficiency and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

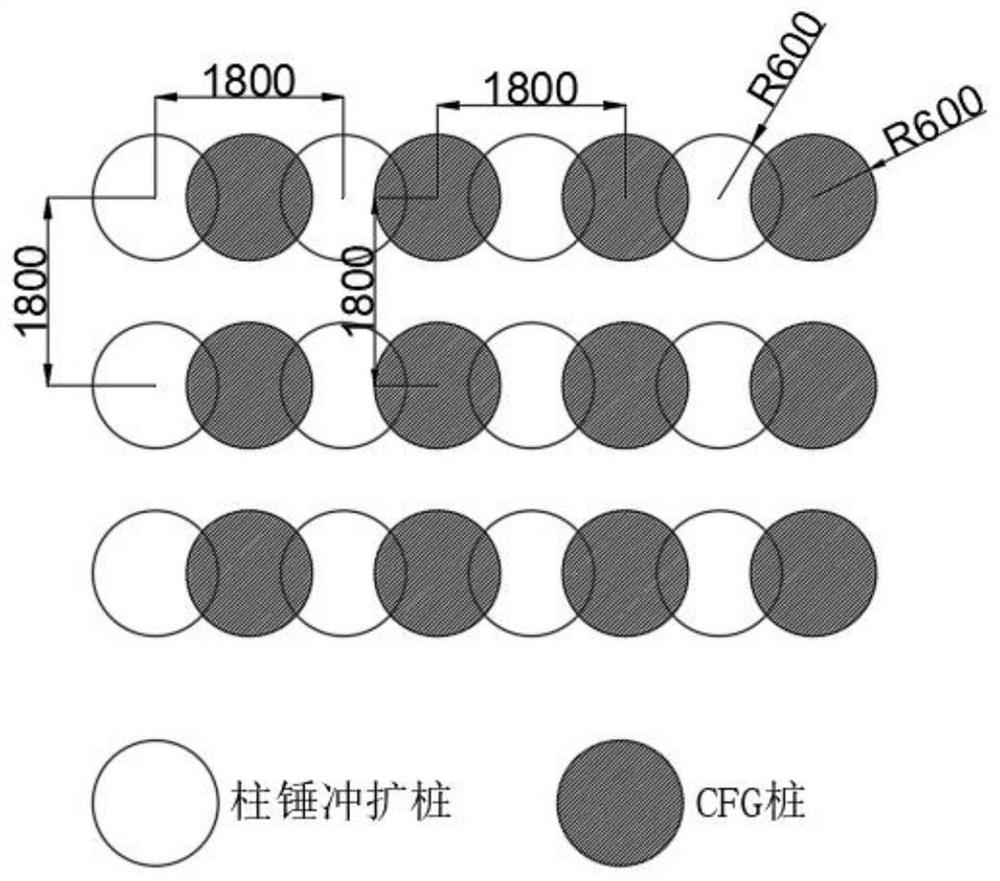

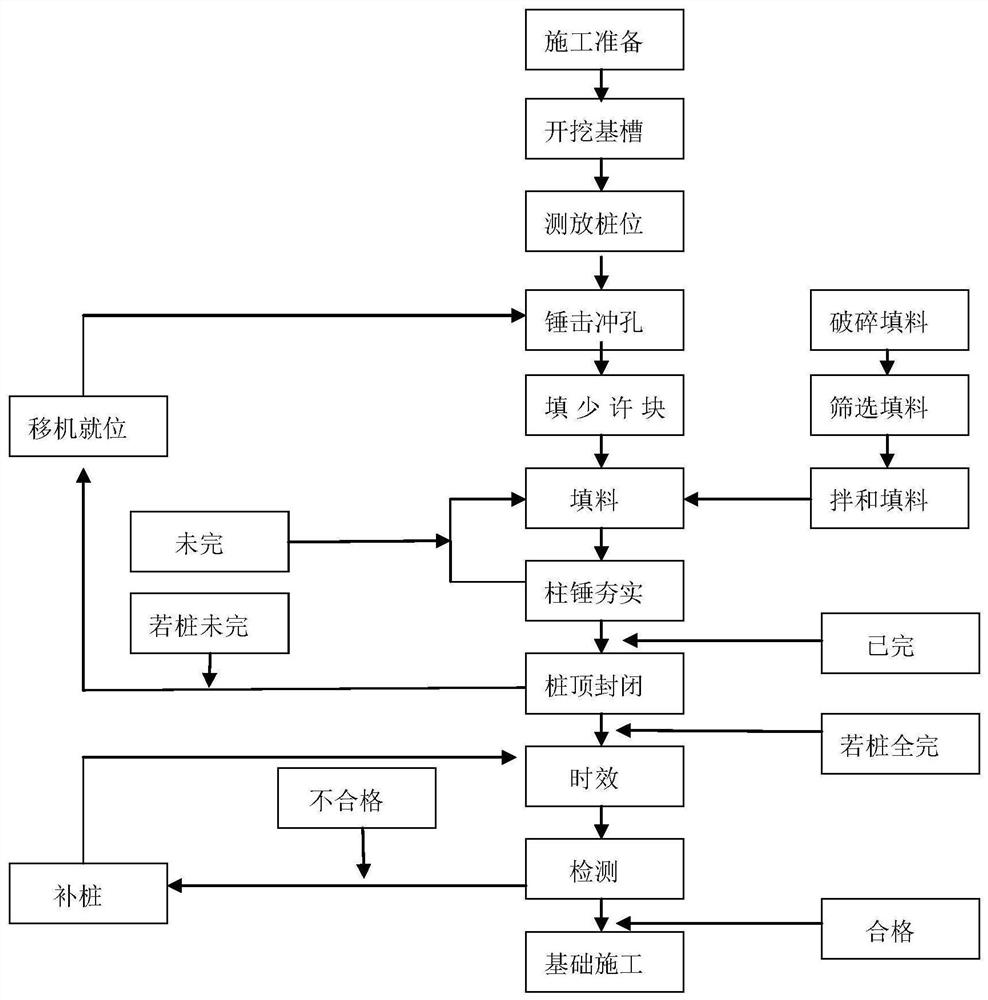

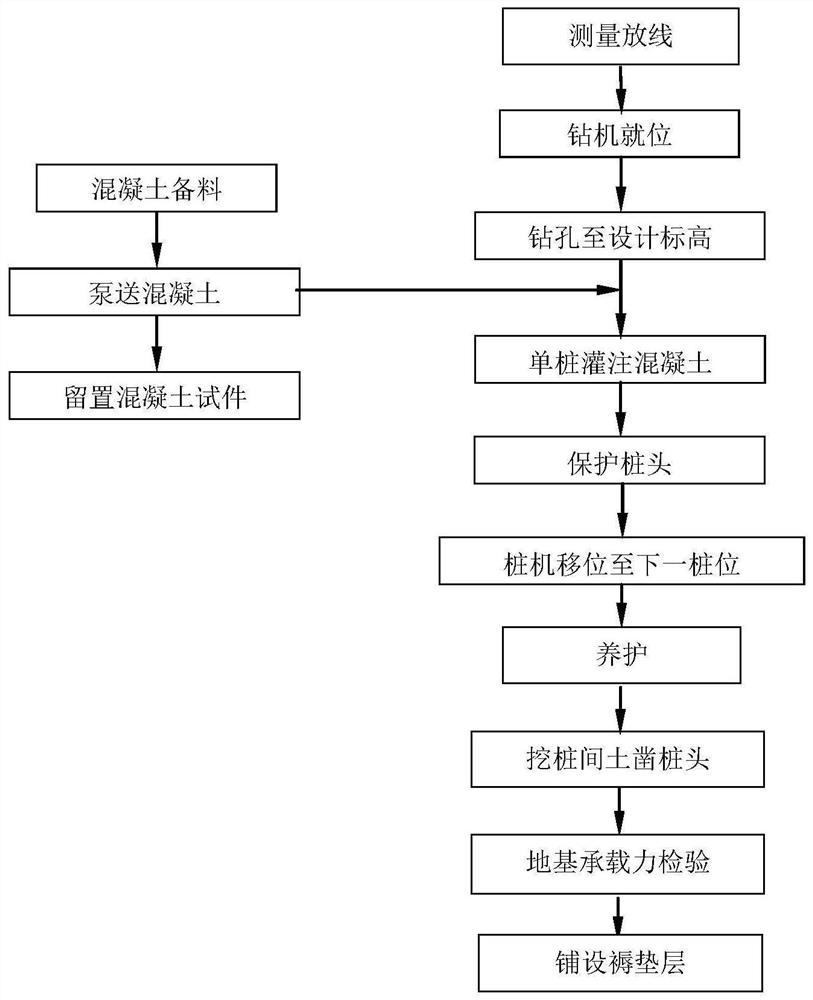

[0076] see Figure 1-7 , in the embodiment of the present invention, a kind of ground reinforcement construction technology of large-scale hydraulic structure of construction waste ground layer, the steps are as follows:

[0077] S1. Construction of Pile Expansion with Column Hammer

[0078] 1) Measuring and setting out

[0079] After the site is excavated to the elevation of the piling work surface, the positioning and setting out shall be carried out according to the measurement data provided by the owner, and the supervisory engineer shall be invited to inspect the line;

[0080] 2) Measure and place the pile position

[0081] After the inspection line is qualified, start to place the pile positions according to the design requirements. First, use the electronic theodolite to determine the control points of each axis according to the control points, and then surround the rectangular range where the pile points need to be placed with a white line, and then according to the...

Embodiment 2

[0125] In an embodiment of the present invention, a foundation reinforcement construction process of a large-scale hydraulic structure in the ground layer of construction waste, the steps are as follows:

[0126] S1. Construction of Pile Expansion with Column Hammer

[0127] 1) Measuring and setting out

[0128] After the site is excavated to the elevation of the piling work surface, the positioning and setting out shall be carried out according to the measurement data provided by the owner, and the supervisory engineer shall be invited to inspect the line;

[0129] 2) Measure and place the pile position

[0130] After the inspection line is qualified, start to place the pile positions according to the design requirements. First, use the electronic theodolite to determine the control points of each axis according to the control points, and then surround the rectangular range where the pile points need to be placed with a white line, and then according to the axis line The re...

Embodiment 3

[0174] In an embodiment of the present invention, a foundation reinforcement construction process of a large-scale hydraulic structure in the ground layer of construction waste, the steps are as follows:

[0175] S1. Construction of Pile Expansion with Column Hammer

[0176] 1) Measuring and setting out

[0177] After the site is excavated to the elevation of the piling work surface, the positioning and setting out shall be carried out according to the measurement data provided by the owner, and the supervisory engineer shall be invited to inspect the line;

[0178] 2) Measure and place the pile position

[0179]After the inspection line is qualified, start to place the pile positions according to the design requirements. First, use the electronic theodolite to determine the control points of each axis according to the control points, and then surround the rectangular range where the pile points need to be placed with a white line, and then according to the axis line The rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com