Bonded magnet and preparation method thereof

A technology of bonded magnets and inorganic binders, which is applied in the direction of magnetic objects, inductors/transformers/magnets, magnetic materials, etc., and can solve the problems of high production cost and low production efficiency of anisotropic NdFeB bonded magnets , to achieve the effect of strong shape retention and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

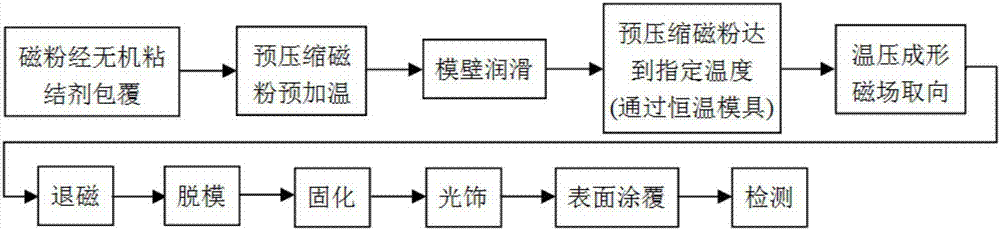

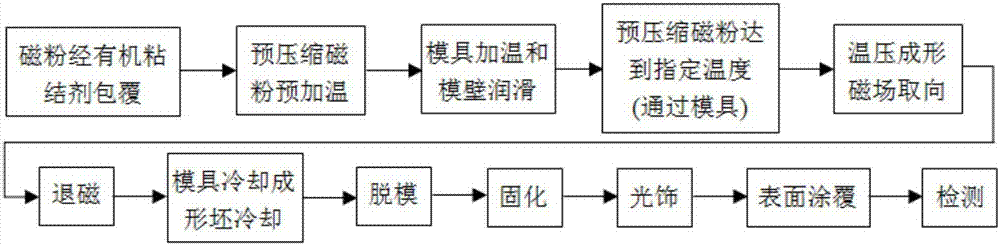

Method used

Image

Examples

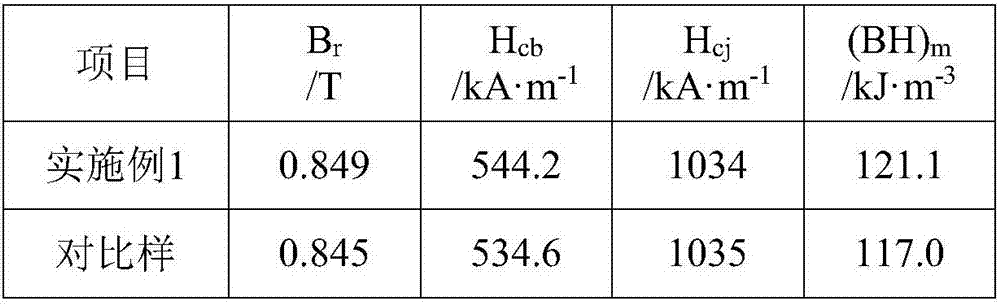

Embodiment 1

[0053] Commercially available BMND-15P magnetic powder produced by Beikuang Magnetic Materials Co., Ltd. was used. The magnetic powder has been subjected to surface passivation and high temperature oxidation resistance treatment in advance.

[0054] (1) Dissolving sodium silicate equivalent to 2.0% of the weight of the magnetic powder through deionized water to obtain a sodium silicate solution, the concentration of the sodium silicate solution is controlled at 15 to 18wt%; the magnetic powder is put into the sodium silicate solution to form Magnetic powder-sodium silicate solution suspension, the suspension is evacuated, heated and stirred in special equipment to completely volatilize the solvent, and obtain dry pre-compressed magnetic powder uniformly coated with sodium silicate;

[0055] (2) Add molybdenum disulfide equivalent to 0.3% of the weight of the pre-compressed magnetic powder in the pre-compressed magnetic powder, and fully mix to obtain the pre-compressed mixed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com