Preparing method for titanium-based coating titanium anode

A titanium anode and coating technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of high electrode potential, poor surface roughening uniformity, breakdown, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

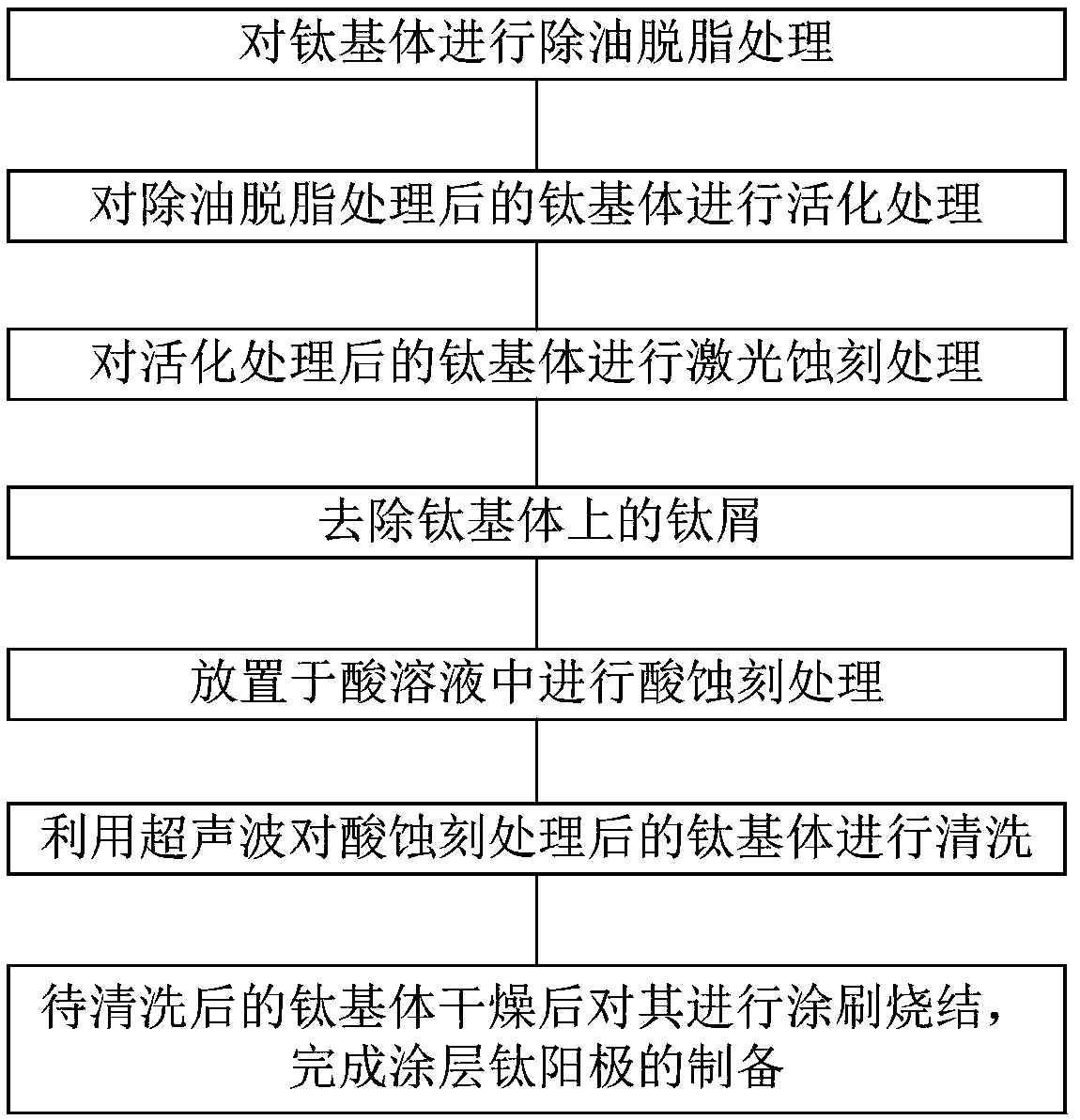

[0030] see figure 1 Shown is a schematic flow chart of the preparation method of the titanium-based coated titanium anode provided by the present invention. The preparation method specifically includes the following steps:

[0031] 1) Degreasing and degreasing the titanium substrate;

[0032] 2) activating the titanium substrate after degreasing and degreasing treatment;

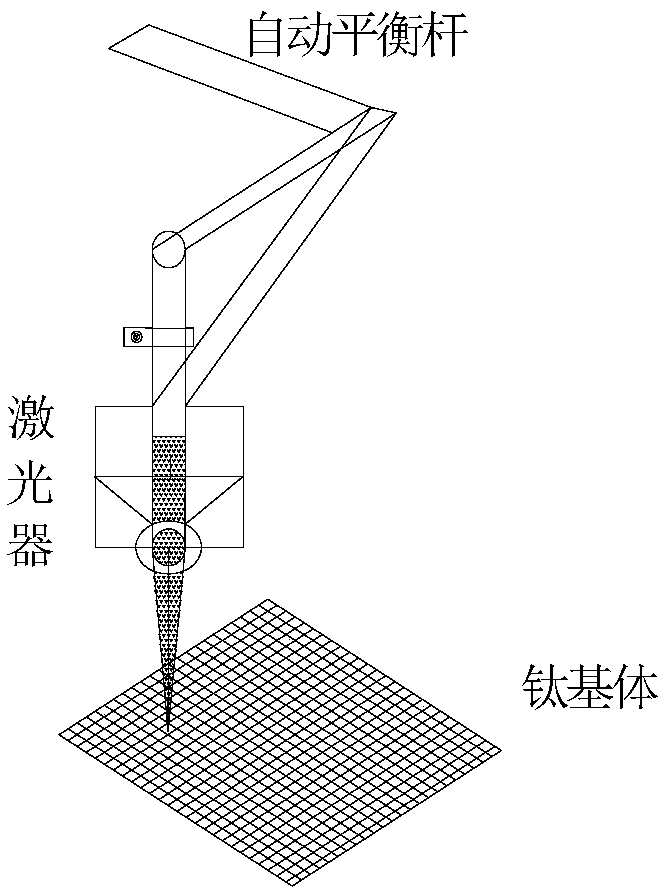

[0033] 3) performing laser etching on the activated titanium substrate;

[0034] 4) removing titanium chips on the titanium substrate;

[0035] 5) placing the titanium substrate treated in step 4) in an acid solution for acid etching;

[0036] 6) cleaning the acid-etched titanium substrate by ultrasonic waves;

[0037] 7) After the cleaned titanium substrate is dried, it is brushed and sintered to complete the preparation of the coated titanium anode.

[0038] Further, the grid size of the laser etching in the step 2) is 0.02mm-1.5mm.

[0039] Further, the acid solution in step 5) is a mixed acid solut...

Embodiment 2

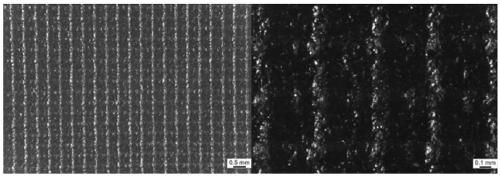

[0046] In order to prove the feasibility of the preparation method provided by the invention, Figure 3-Figure 5 is through figure 2 Model research, experiments were carried out in oxygen-evolving and hydrogen-evolving anodes, the coating system was Ir-Ta system formula and platinum-plated anodes, and the sintering and spraying processes were repeated, and finally the surface structure of the coating seen from the microscope can be clearly seen Seeing that the coating is in a regular arrangement, SEM-EDS found that the IrO of the coating 2The active points are evenly distributed and the coating has less cracks, which can meet the requirements of the coating surface performance.

[0047] When the coated titanium anode is a chlorine-analyzing electrode, for example, a ruthenium-iridium-titanium (RuIranTi) anode sample has a size of 80 mm × 50 mm × 2 mm, which is treated by laser surface etching, and whose grid size is 0.2 mm × 0.2 mm, prepared by brushing Single side coated e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com