Electric arc spraying wire as well as preparation and spraying methods thereof

A technology of arc spraying and wire material, applied in the spraying method, can solve the problems of poor corrosion resistance, lower high temperature resistance, corrosion resistance, poor distribution uniformity of coating metal phase and ceramic phase, etc., to achieve enhanced mechanical properties and corrosion resistance , enhance high temperature resistance and heat reflectivity, increase the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The aluminum-based ceramic powder core wire material and the arc spraying process of the present embodiment consist of the following characteristic steps:

[0045] 1) Powder core ratio: Al with particle size of 1-200μm 2 o 3 Powder, Al with a particle size of 500-990 nanometers 2 o 3 Powder, particle size 1~50μmSiO 2 Powder and SiO with a particle size of 500-900 nanometers 2 The powder is mixed according to the mass ratio of 97:1.5:1:0.5, and finally the powder is poured into the mixer and fully stirred;

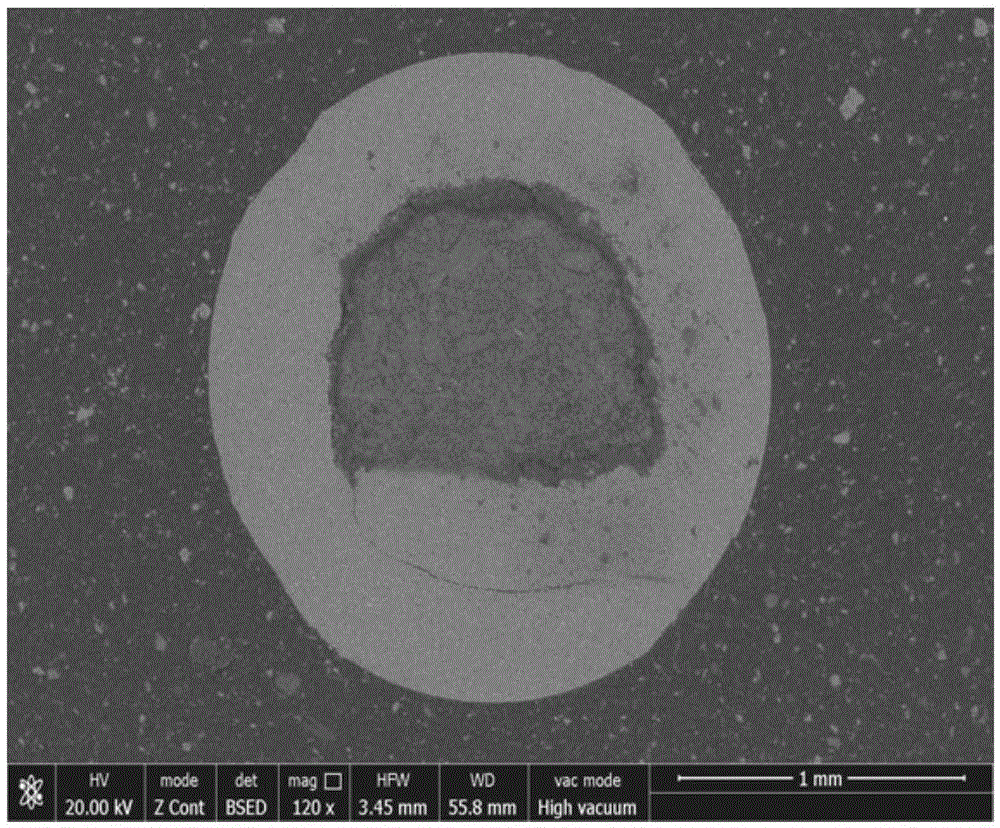

[0046] 2) Spraying wire preparation: select the aluminum strip with a width of 12 mm and grade 5052 as the skin of the spraying wire, fill it with the powder core obtained in step 1) after bending, and wrap and draw it into a spraying wire with an outer diameter of about 2 mm. The filling ratio of the powder core is 20.3%, and the diameter of the spraying wire is 2.02mm;

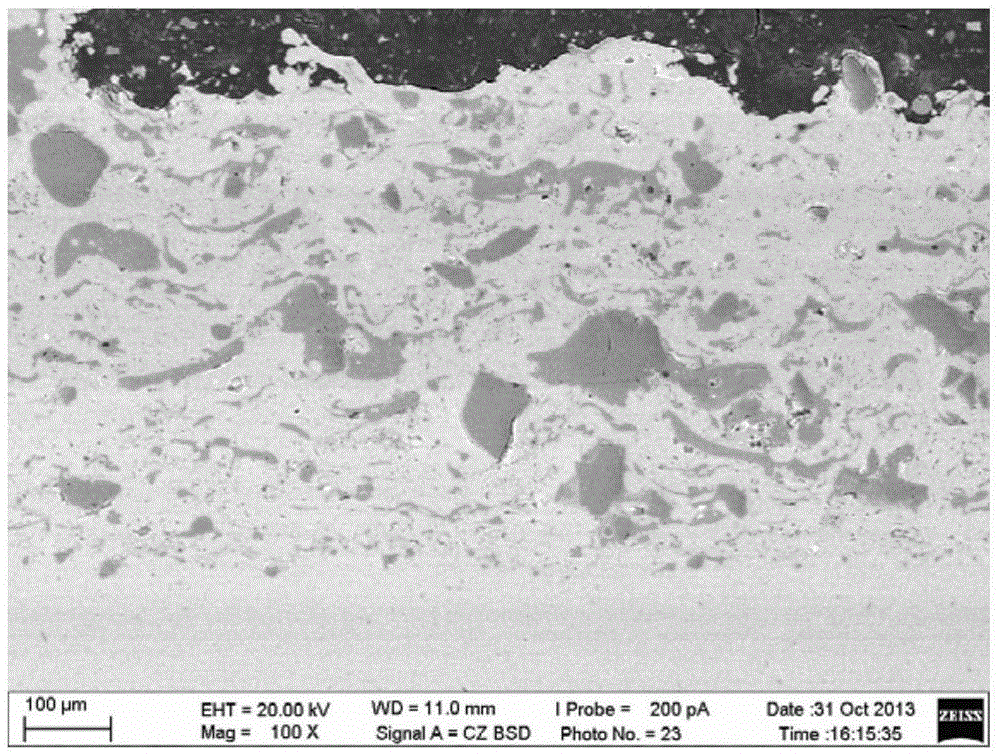

[0047] 3) The aluminum-based ceramic powder core wire material prepared in step 2) of thi...

Embodiment 2

[0051] The aluminum-based ceramic powder core wire material and the arc spraying process of the present embodiment consist of the following characteristic steps:

[0052] 1) Powder core ratio: Al with particle size of 1-200μm 2 o 3 Powder, Al with a particle size of 500-990 nanometers 2 o 3 Powder, particle size 1~50μmSiO 2 Powder and SiO with a particle size of 500-900 nanometers 2 The powder is mixed according to the mass ratio of 98:1:0.9:0.1, and finally the powder is poured into the mixer and fully stirred;

[0053] 2) Spraying wire preparation: select the aluminum strip with a width of 8 mm and grade 5052 as the skin of the spraying wire, fill it with the powder core obtained in step 1) after bending, and wrap and draw it into a spraying wire with an outer diameter of about 2 mm, wherein The filling ratio of the powder core is 27.8%, and the diameter of the spraying wire is 2.01mm;

[0054] 3) The aluminum-based ceramic powder core wire material prepared in step 2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com