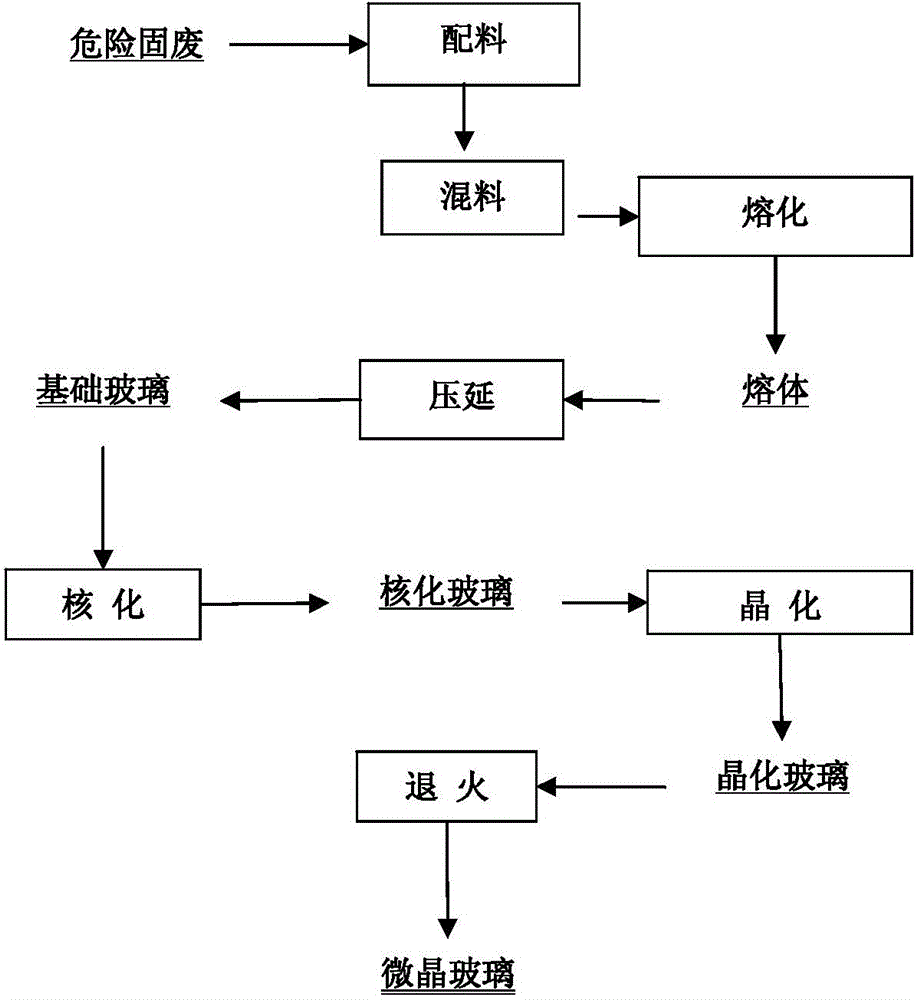

Method for preparing microcrystalline glass from hazardous solid wastes

A technology of glass-ceramic and waste glass, which is applied in the field of environmental protection and resource reuse, can solve the problems of unsafe disposal of dangerous solids, heavy metal pollution, serious secondary pollution, etc., and achieve high value of harmless solids Utilization, significant environmental protection and economic benefits, low leaching concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

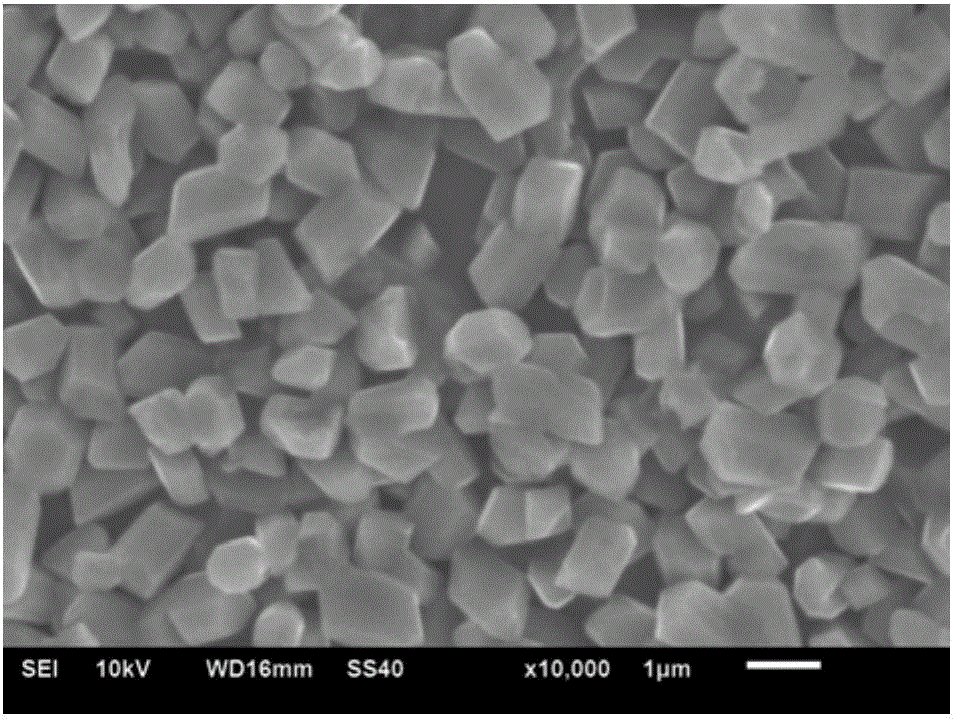

[0045] Mix 60.0wt.% of waste incineration ash and 40.0wt.% of waste glass evenly, and the mixture contains Cr 0.8 wt.%, Pb 1.4 wt.%, Ni 2.0 wt.%, Cd 2.0 wt.%, Zn 5.0 wt.% , Cu 2.1 wt.%. The mixture is heated to 1550°C to melt to obtain a melt, which is rolled to obtain a basic glass, then heated to 750°C to nucleate to obtain a nucleated glass, and then heated to 950°C to crystallize to form a crystallized glass with uniform distribution of crystallites, and finally annealed to eliminate Stress results in a glass-ceramic product. The bending strength of the glass-ceramic is 70.0 MPa, the microhardness is 6.0GPa, the compressive strength is 450.0MPa, and the wear amount is 0.040g / cm 2 , the acid resistance (20wt% sulfuric acid) is 96.0%, the alkali resistance (20wt% sodium hydroxide) is 98.0%, the leaching concentration of Cr is 0.2 mg / L, the leaching concentration of Pb is 0.07 mg / L, and the leaching concentration of Cd is 0.6 mg / L, the leaching concentration of Ni is 0.25 ...

Embodiment 2

[0047] Mix 50 wt.% of stainless steel slag and 50 wt.% of quartz sand evenly, and the mixture contains Cr 4.0 wt.%, Pb 0 wt.%, Ni 0.5 wt.%, Cd 0 wt.%, Zn 0.7 wt.%, Cu 1.1 wt.%. The mixture is heated to 1550°C to melt to obtain a melt, which is rolled to obtain a basic glass, then heated to 750°C to nucleate to obtain a nucleated glass, and then heated to 950°C to crystallize to form a crystallized glass with uniform distribution of crystallites, and finally annealed to eliminate Stress results in a glass-ceramic product. The bending strength of the glass-ceramic is 150.0MPa, the microhardness is 7.8GPa, the compressive strength is 792.0MPa, and the wear amount is 0.100g / cm 2 , the acid resistance (20wt% sulfuric acid) is 97.1%, the alkali resistance (20wt% sodium hydroxide) is 98.4%, the leaching concentration of Cr is 5.0 mg / L, the leaching concentration of Pb is 0 mg / L, and the leaching concentration of Cd is 0 mg / L, the leaching concentration of Ni is 0.15 mg / L, the leac...

Embodiment 3

[0049] Mix 20wt.% of electroplating sludge, 40wt.% of limestone and 40wt.% of waste glass evenly. The mixture contains Cr 2.4 wt.%, Pb 1.4 wt.%, Ni 0 wt.%, Cd 1.2 wt.%, Zn 3.5 wt.%, Cu 5.0 wt.%. The mixture is heated to 1550°C to melt to obtain a melt, which is rolled to obtain a basic glass, then heated to 750°C to nucleate to obtain a nucleated glass, and then heated to 950°C to crystallize to form a crystallized glass with uniform distribution of crystallites, and finally annealed to eliminate Stress results in a glass-ceramic product. The bending strength of the glass-ceramic is 100.0 MPa, the microhardness is 6.5GPa, the compressive strength is 550.0MPa, and the wear volume is 0.050g / cm 2 , the acid resistance (20wt% sulfuric acid) is 98.2%, the alkali resistance (20wt% sodium hydroxide) is 98.8%, the leaching concentration of Cr is 0.22 mg / L, the leaching concentration of Pb is 0.15 mg / L, and the leaching concentration of Cd is 0.11 mg / L, the leaching concentration of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com