Method for preparing nutrient grain breakfast with high crispness in hot milk

A technology of cereal breakfast and hot milk, which is applied in the field of deep processing of cereals, can solve the problems of insufficient nutritional content, unpopularity of consumers, and softening of products after water absorption, and achieve the effects of fine pores, moderate puffing degree, and lower water absorption index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

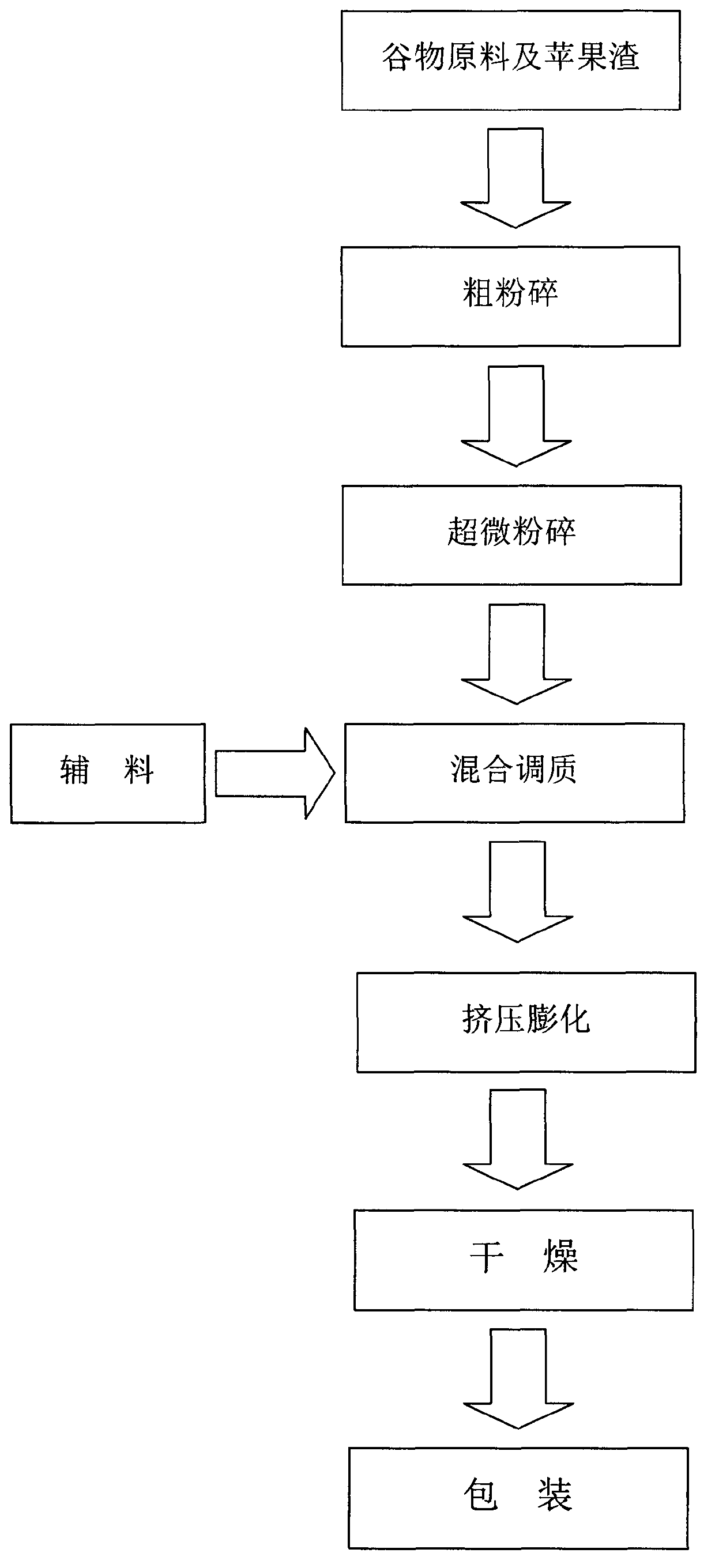

Image

Examples

Embodiment 1

[0024] Take 400g of corn, 300g of wheat, 200g of oats, 100g of red beans, and 60g of dried apple pomace. After coarse pulverization, put the superfine raw material powder into a high-speed mixer and mix well. At the same time, add 30g of white sugar and 40g of cream , eggshell powder / shell powder 40g, diacetyl tartaric acid monoglyceride 2.5g, adjust the water content to 23% and continue to stir and mix evenly. Put the conditioned raw materials into a twin-screw extruder for extrusion and puffing. The extrusion conditions are: the temperature in zone I is 75°C, the temperature in zone II is 95°C, the temperature in zone III is 115°C, and the temperature in IV is 155°C. The screw speed is 130 rpm. The extruded spherical cereal breakfast granules were dried at 110°C for 20 minutes, taken out and cooled to room temperature, and packaged to be the final product.

Embodiment 2

[0026] Take 350kg of corn, 250kg of wheat, 120kg of oats, 100kg of red beans, and 80kg of dried apple pomace. After coarse crushing, put the superfine raw material powder into a high-speed mixer and mix them evenly. At the same time, add 25kg of white sugar and 50kg of cream. , eggshell powder / shell powder 50kg, diacetyl tartrate monoglyceride 3kg, adjust the water content to 23% and continue to stir and mix evenly. Put the conditioned raw materials into a twin-screw extruder for extrusion and puffing. The extrusion conditions are: the temperature in zone I is 75°C, the temperature in zone II is 95°C, the temperature in zone III is 115°C, and the temperature in IV is 155°C. The screw speed is 130 rpm.

[0027] The extruded spherical cereal breakfast granules are dried at 120°C for 15 minutes, taken out and cooled to room temperature, and packaged to be the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com