Lithium-ion battery separator prepared by polyethylene mixture and preparation method of lithium-ion battery separator

A technology of polyethylene microporous film and polyethylene, which is applied in the direction of secondary batteries, battery components, circuits, etc., can solve the unfavorable oriented lamella structure, and can not continuously and stably prepare cast base film and lamella growth Slow down the speed and other problems to achieve the effect of expanding the range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Select the weight average molecular weight as 1.68×10 6 The ultra-high molecular weight polyethylene (UHMWPE-2) and the HDPE-3 resin in Comparative Example 1 are 5:95 according to the mass ratio (using the original, unswollen ultra-high molecular weight polyethylene UHMWPE-2 and HDPE-3 The mass ratio of the resin) is blended in two ways:

[0075] (1) Directly melt blend UHMWPE-2 and HDPE-3 resin on a twin-screw extruder;

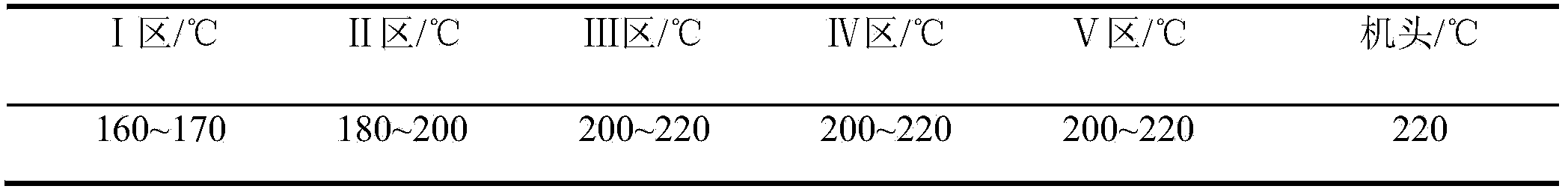

[0076](2) First use liquid paraffin with a molecular weight of 150 as a swelling agent to swell UHMWPE-2 in a stainless steel reactor. The mass ratio of UHMWPE-2 to liquid paraffin is 10:90, and the swelling conditions are: nitrogen protection, 160°C , 12 hours; after cooling, a gel-like UHMWPE-2 was obtained. Melt and blend the jelly-like UHMWPE-2 and HDPE-3 resins on a twin-screw extruder. The temperature settings of each zone of the twin-screw extruder are: 170, 200, 220, 220, 220°C, and the head temperature is 220°C ℃. The extruded product is ...

Embodiment 2

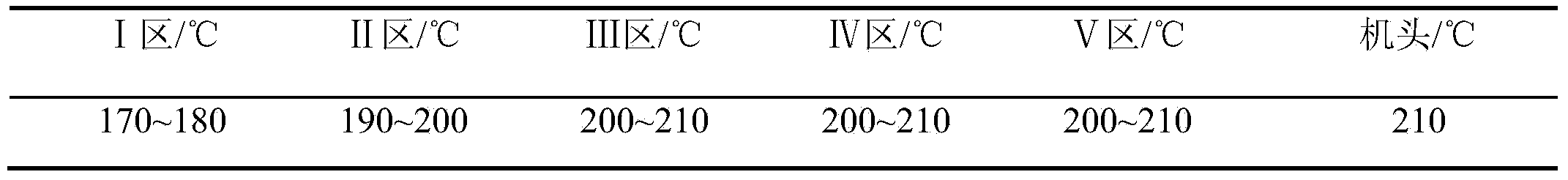

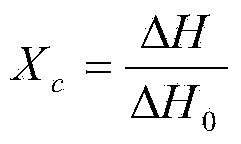

[0084] Using the UHMWPE-2 and HDPE-3 resins in Example 1, UHMWPE-2 is swelled according to the swelling conditions in Example 1, and the jelly-like UHMWPE-2 and HDPE-3 resin obtained after cooling are processed in a twin-screw Melt blending on the extruder, the process conditions of the twin-screw extruder are the same as in Example 1, and the blending mass ratios of UHMWPE-2 and HDPE-3 are respectively: 1:99, 3:97, 7:93 and 10: 90 (both based on the mass ratio of the original, unswollen ultra-high molecular weight polyethylene UHMWPE-2 to HDPE-3 resin). According to the extrusion casting process conditions, heat treatment process conditions and cold and hot stretching process conditions in Example 1, the four kinds of blended modified resins were respectively subjected to extrusion casting film formation, heat treatment and stretching to form holes, and determined The parameters of the oriented lamellar structure of the cast base film and the performance parameters of the mic...

Embodiment 3

[0090] Select the weight average molecular weight as 1.35×10 6 , 1.97×10 6 and 2.53×10 6 The three kinds of ultra-high molecular weight polyethylene, respectively denoted as: UHMWPE-1, UHMWPE-3, UHMWPE-4. According to the swelling conditions in Example 1, the three kinds of UHMWPE were swelled, and after cooling, jelly-like UHMWPE was obtained. UHMWPE and the HDPE-3 resin in Comparative Example 1 are based on a mass ratio of 5:95 (based on the mass ratio of the original, unswollen ultra-high molecular weight polyethylene and HDPE-3 resin), in a twin-screw extrusion Melt blending was carried out on the machine, and the process conditions of the twin-screw extruder were the same as in Example 1. According to the extrusion casting process conditions, heat treatment process conditions and cold and hot stretching process conditions in Example 1, the three kinds of blended modified resins were respectively subjected to extrusion casting film formation, heat treatment and stretchi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Puncture strength | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com