High-temperature metal hard seal ball valve for granular media

A hard-sealed, granular technology, used in shaft seals, valve details, valve devices, etc., can solve the problems of thick overall structure and large flow resistance of the valve plate, achieve good seizure resistance, improve processing accuracy, and prevent sealing pairs. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solutions and advantages of the present invention clearer, below in conjunction with embodiment and accompanying drawing, the present invention is described in further detail:

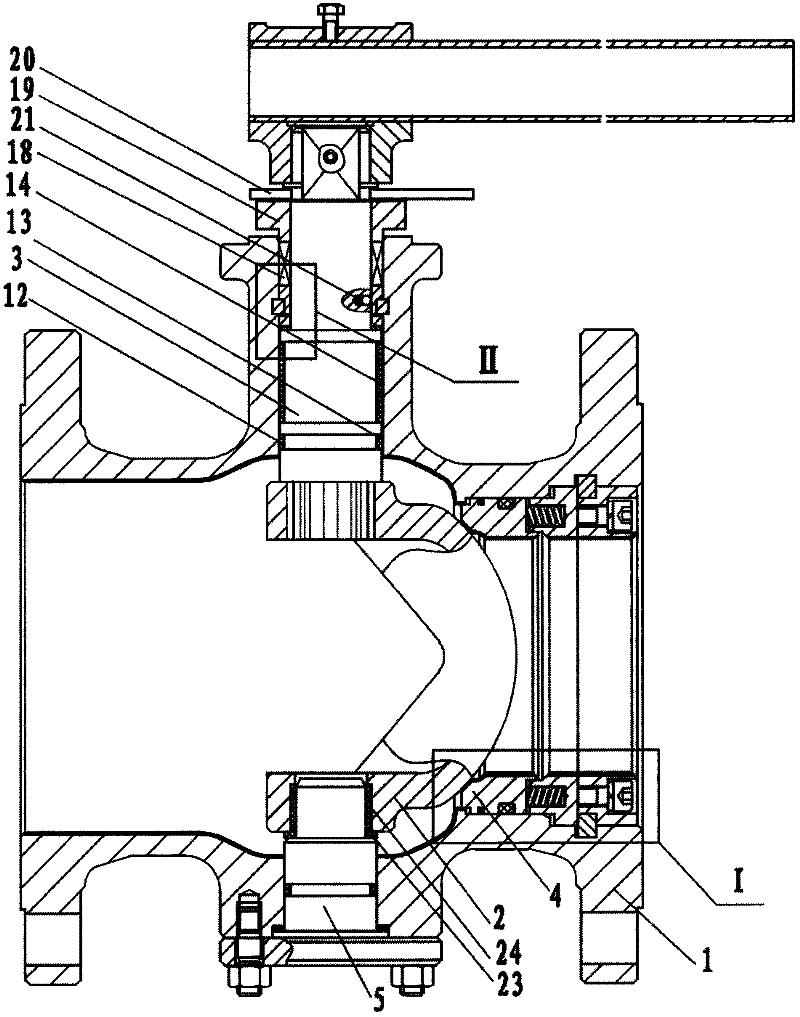

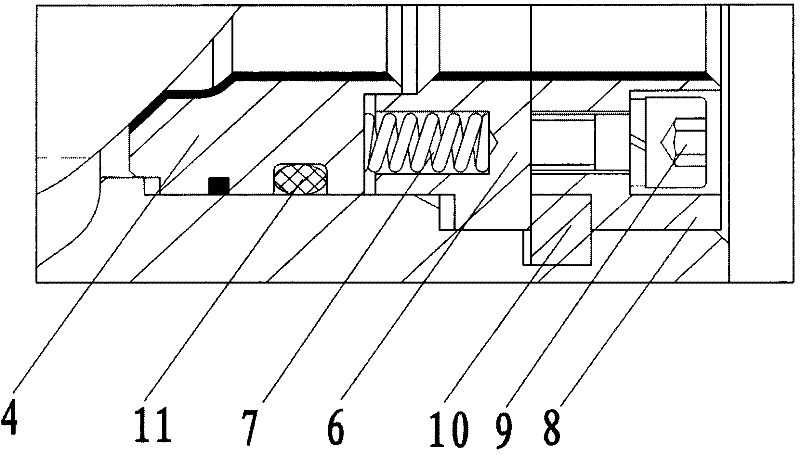

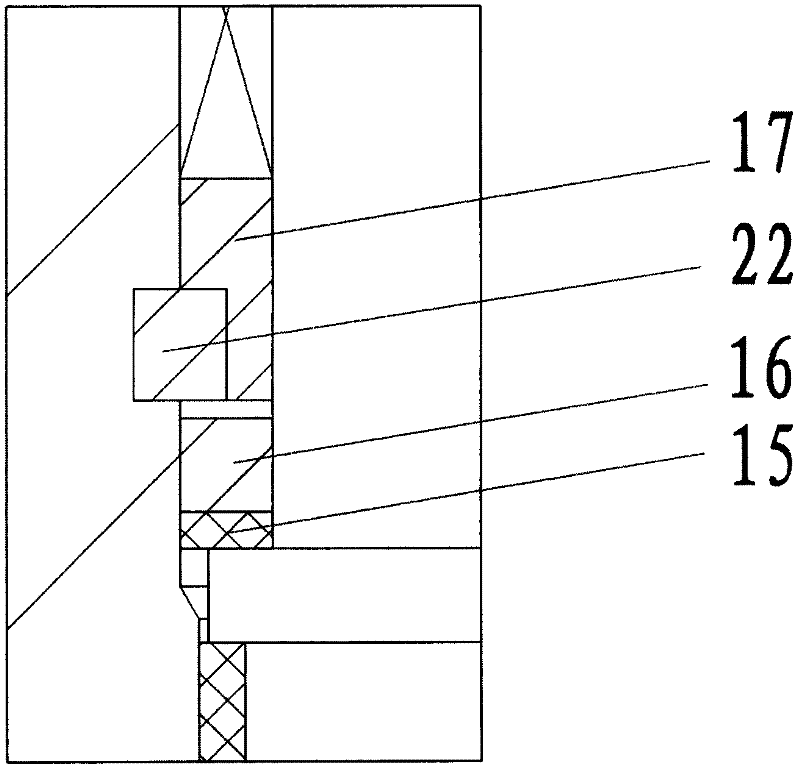

[0036] figure 1The structure of the high-temperature metal hard-sealed ball valve for granular media of the present invention is illustrated. The ball valve includes a valve body 1, a ball 2, a valve stem 3, a valve seat 4 and a bottom cover 5. The ball is arranged in a chamber inside the valve body. The valve stem connected with the sphere to drive the sphere protrudes out of the valve body through the upper central through hole of the valve body, and the bottom cover is located at the bottom of the valve body, including a bottom cover bottom plate 51 and a bottom cover shaft 52, see Figure 4 . The base plate of the bottom cover is movably connected with the valve body, and the shaft of the bottom cover passes through the through hole at the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com