Large-sized high-power graphite electrode and manufacturing method thereof

A graphite electrode and manufacturing method technology, applied in the manufacture of stone grinding electrodes, large-scale high-power graphite electrodes and their manufacturing fields, can solve problems such as slow production efficiency, high input costs, and high manufacturing difficulty coefficient, and achieve enhanced waste utilization transformation, increasing economic benefits, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

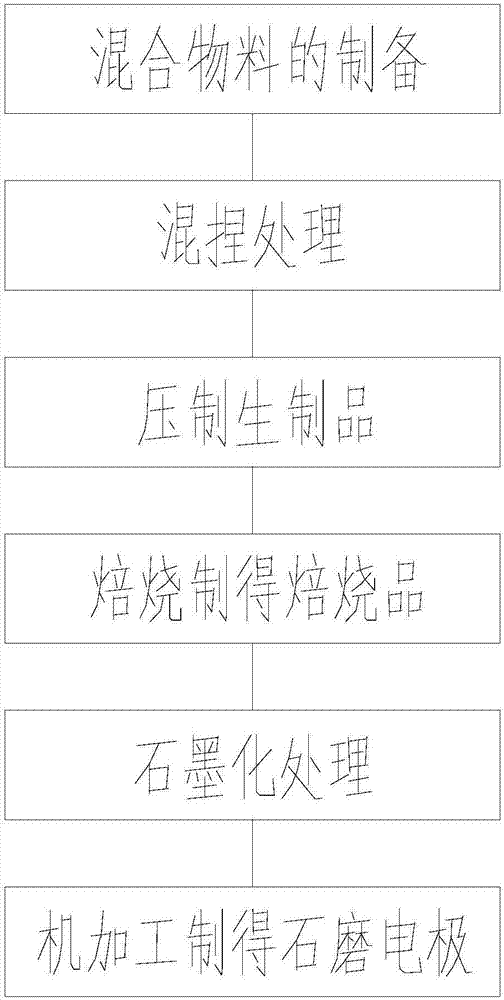

[0032] The manufacturing method of large-scale high-power graphite electrode of the present invention, its overall process is roughly: use forged petroleum coke and needle coke as dry material, dry material is made into different granularity and powder material through crushing and screening, and simultaneously mixes Use crushed graphite and raw crushed graphite, mix according to a certain ratio to form a mixed material, use medium-temperature improved pitch with high coking value as a binder in a kneading pot, add stearic acid additives for kneading to obtain a paste, and mix the paste The raw material is added to the uniformly cooled cooling system for cooling, and then extruded under a 41MN extruder to produce raw products, and then roasted, graphitized, and machined to produce large-scale high-power stone grinding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com