Application of ultra-high early strength polycarboxylic acid water reducer to preparation of precast concrete component

A technology of prefabricated components and strong polycarboxylate, applied in the field of super-early-strength polycarboxylate superplasticizer, can solve the problems of long mold turnover period, slow strength growth, long setting time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

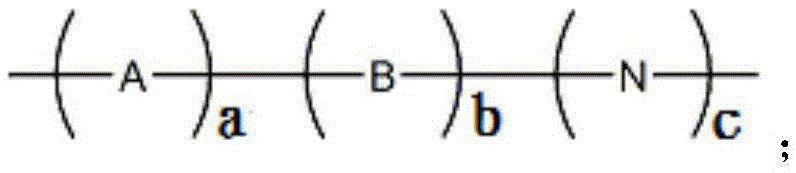

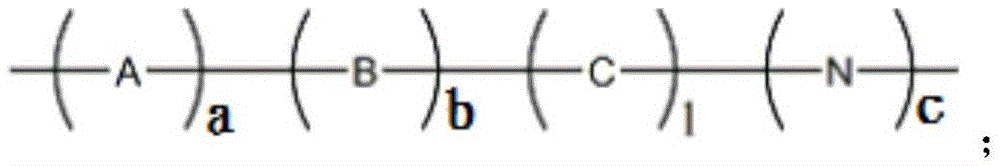

Method used

Image

Examples

Embodiment 1

[0089] A kind of embodiment of the preparation method of concrete prefabricated member described in the present invention, described method comprises the following steps:

[0090] The concrete is poured into the mold to obtain the primary body of the prefabricated component. After the primary body of the prefabricated component is naturally cured for 12 hours, the demoulding strength reaches 30 MPa, and then the natural curing is continued to obtain the concrete prefabricated component.

[0091] The concrete comprises the following components by weight: 370 parts of cement, 715 parts of sand, 1025 parts of gravel, 80 parts of fly ash, 5 parts of super early strength polycarboxylate superplasticizer and 135 parts of water.

[0092] The super early strength polycarboxylate water reducer is prepared by the following method:

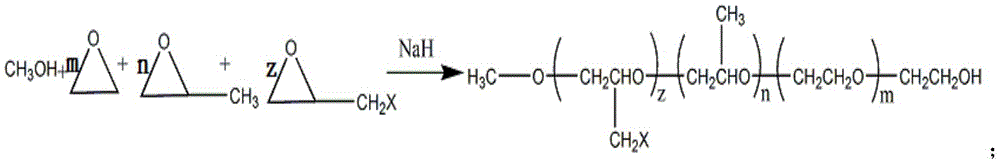

[0093] (1) Synthesis of methoxyl hydroxyl PEG intermediate

[0094] Inject 5mol of methanol, 25mol of ethylene oxide, 5mol of epichlorohydrin and 1g of sodiu...

Embodiment 2

[0102] A kind of embodiment of the preparation method of concrete prefabricated member described in the present invention, described method comprises the following steps:

[0103] The concrete is poured into the mold to obtain the initial body of the prefabricated component, and after 15 hours of natural curing of the primary body of the prefabricated component, the demoulding strength reaches 35 MPa, demoulding, and then the natural curing is continued to obtain the concrete prefabricated component.

[0104] The concrete comprises the following components by weight: 405 parts of cement, 735 parts of sand, 1040 parts of gravel, 120 parts of fly ash, 8 parts of super early strength polycarboxylate superplasticizer and 145 parts of water.

[0105] The super early strength polycarboxylate water reducer is prepared by the following method:

[0106] (1) Synthesis of methoxyl hydroxyl PEG intermediate

[0107] Inject 5mol methanol, 1000mol ethylene oxide, 250mol propylene oxide, 75...

Embodiment 3

[0115] A kind of embodiment of the preparation method of concrete prefabricated member described in the present invention, described method comprises the following steps:

[0116] The concrete was poured into the mold to obtain the initial body of the prefabricated component, and after natural curing of the initial body of the prefabricated component for 13 hours, the demoulding strength reached 33.5 MPa. After demoulding, the natural curing is continued to obtain the concrete prefabricated components.

[0117] The concrete comprises the following components by weight: 380 parts of cement, 720 parts of sand, 1028 parts of gravel, 90 parts of fly ash, 5.5 parts of super early strength polycarboxylate superplasticizer and 136 parts of water.

[0118] The super early strength polycarboxylate water reducer is prepared by the following method:

[0119] (1) Synthesis of methoxyl hydroxyl PEG intermediate

[0120] Inject 5 mol of methanol, 50 mol of ethylene oxide, 500 mol of epoxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Release strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com