Modified ultra-high molecular weight polyethylene fiber forming special material, and preparation method and melt spinning fiber forming method thereof

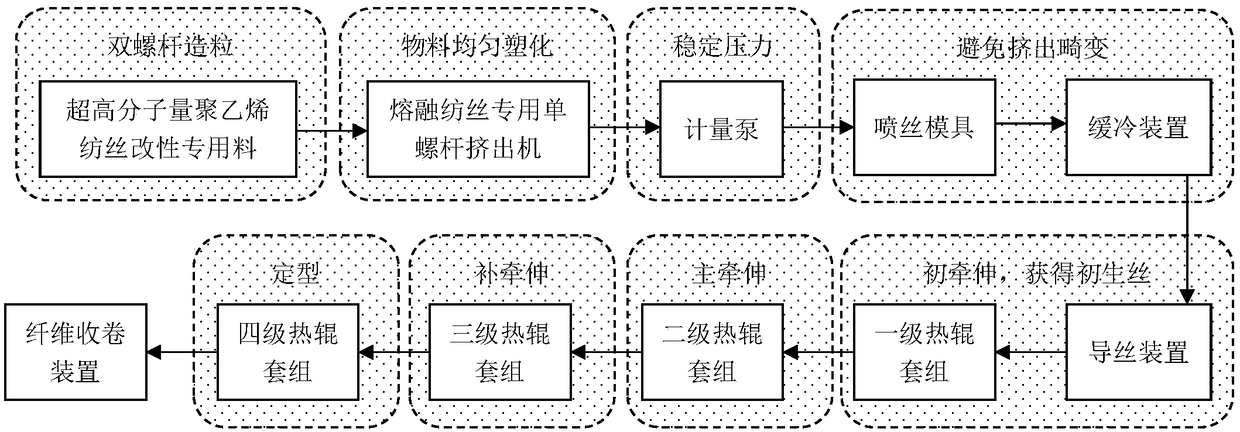

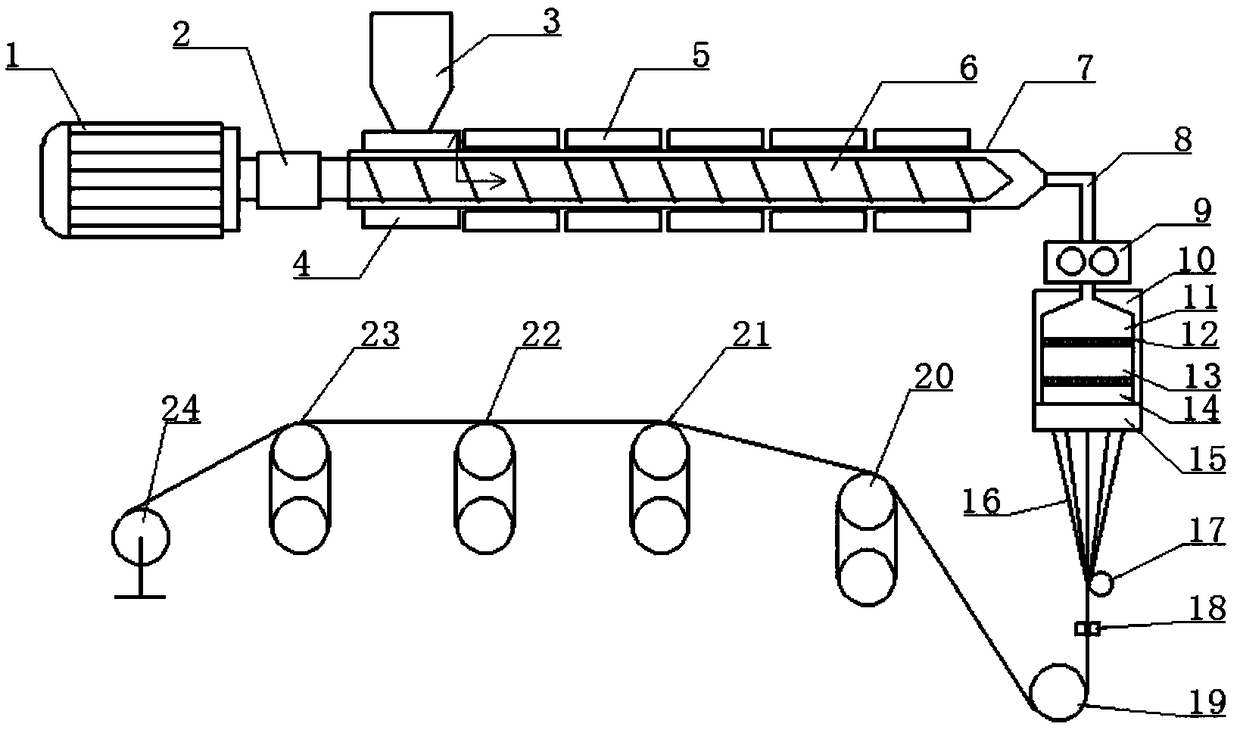

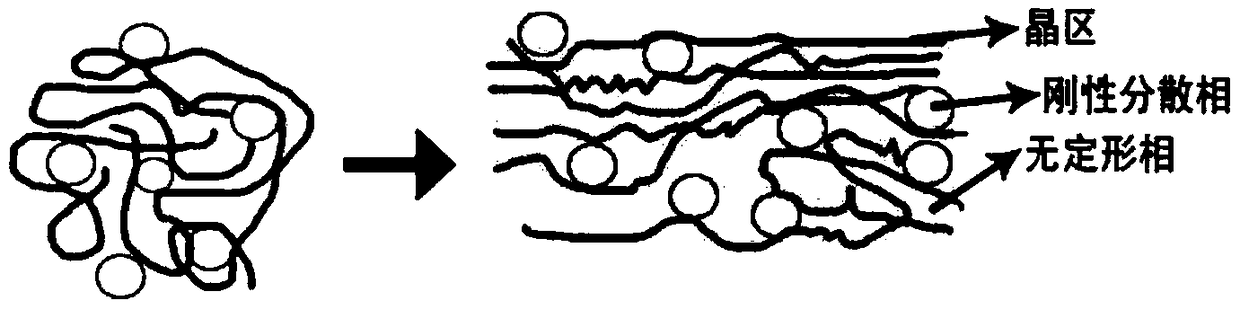

An ultra-high molecular weight, melt-spinning technology, applied in the field of high-strength fiber materials, can solve problems such as extrusion distortion, adhesion-slip flow, etc., achieve good mechanical properties, uniform and dense fiber internal structure, and meet fineness and strength requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Modified ultra-high molecular weight polyethylene fiber-forming special material, raw material composition: select ultra-high molecular weight polyethylene with a viscosity average molecular weight of 1.5 million, high-density polyethylene (melt flow rate 5~7g / 10 min), antioxidant, modified Nano-silica (particle size 30nm), the weight ratio is 60%, 37.2%, 1%, 1.8%, respectively, through high-mixer blending and twin-screw extruder mixing, granulation, to prepare melt-spun pellets.

[0036] The specific modification treatment method of the modified nano-silica is as follows: bake the nano-silica at an oven temperature of 80° C. for 20 minutes; disperse the dried nano-silica in absolute ethanol, add other The titanate coupling agent with a mass fraction of 1.5% is ultrasonically dispersed in a water bath at 80°C for 40 minutes, and the ethanol is completely volatilized at an oven temperature of 85°C to obtain a modified nano-silica, which has a good dispersion effect in po...

Embodiment 2

[0039] Modified ultra-high molecular weight polyethylene fiber-forming special material, raw material composition: select ultra-high molecular weight polyethylene with a viscosity average molecular weight of 1.5 million, high-density polyethylene (melt flow rate 5~7g / 10 min), antioxidant, modified Nano-silica (particle size 30nm), modified nano-titanium dioxide (particle size 100nm), the weight ratio is 70%, 26.5%, 1%, 1.5%, 1%, respectively, through high-mixer blending and twin-screw extrusion Exit the machine to knead and granulate to prepare melt spinning pellets.

[0040] The specific modification treatment method of the modified nano-silica or modified nano-titanium dioxide is as follows: bake the nano-silica or modified nano-titanium dioxide at an oven temperature of 80° C. for 20 minutes; Or the modified nano-titanium dioxide is completely dispersed in absolute ethanol, and a silane coupling agent with a mass fraction of 1.5% is added, ultrasonically dispersed in a wate...

Embodiment 3

[0043] Modified ultra-high molecular weight polyethylene fiber-forming special material, raw material composition: select ultra-high molecular weight polyethylene with a viscosity average molecular weight of 1.5 million, high-density polyethylene (melt flow rate 5~7g / 10 min), antioxidant, modified Nano-silica (particle size 30nm), modified nano-titanium dioxide (particle size 100nm), the weight ratio is 76%, 20%, 1%, 1.8%, 1.2%, respectively, through high-mixer blending and twin-screw extrusion Exit the machine to knead and granulate to prepare melt spinning pellets.

[0044] The specific modification treatment method of the modified nano-silica or modified nano-titanium dioxide is as follows: bake the nano-silica or modified nano-titanium dioxide at an oven temperature of 80° C. for 20 minutes; Or the modified nano-titanium dioxide is completely dispersed in absolute ethanol, and a silane coupling agent with a mass fraction of 1.5% is added, ultrasonically dispersed in a wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow rate | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com