Composite 3D printing method of buried circuit board

A 3D printing and circuit board technology, applied in the field of 3D printing, can solve the problems of not considering the assembly and arrangement of electronic components, the multi-layer circuit board does not have a groove structure, and is not suitable for mass production. The effect of removing restrictions and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

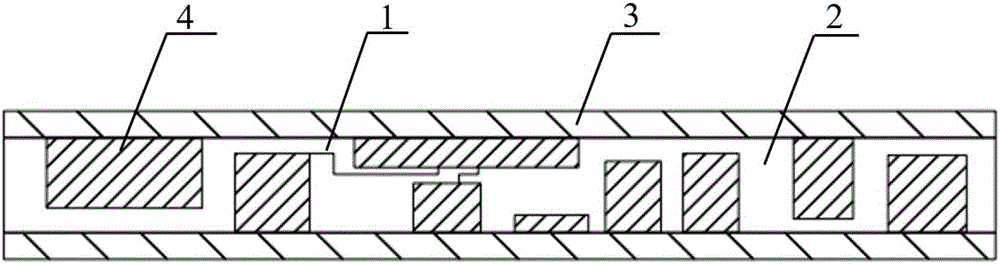

[0048] (1) Use 3D modeling software to design such as figure 1 The structural model of the embedded double-sided circuit board shown, in which 1 is the conductive circuit, 2 is the insulating substrate, 3 is the outer insulating board, and 4 is the electronic component; import the model file into the SLS / SLM forming device, and use the system slice The software slices the model in layers, each layer thickness is 0.03mm, and obtains the data information about the insulating substrate area, conductive line area and groove area in each layered slice;

[0049] (2) Place the nylon 6 powder in the powder feeding cylinder, and place the copper powder in the powder feeding nozzle of the coaxial suction / powder feeding mechanism with dual nozzles, wherein the nylon 6 powder is prepared by solvent precipitation method, and the particle size range is 10-30 μm , Copper powder is produced by gas atomization, the particle size range is 20-40μm, and both powders maintain good sphericity. The...

Embodiment 2

[0055] (1) Use 3D modeling software to design such as figure 1 The structural model of the embedded double-sided circuit board shown, in which 1 is the conductive circuit, 2 is the insulating substrate, 3 is the outer insulating board, and 4 is the electronic component; import the model file into the SLS / SLM forming device, and use the system slice The software slices the model in layers, each layer thickness is 0.01mm, and obtains the data information about the insulating substrate area, conductive line area and groove area in each layered slice;

[0056] (2) Place the nylon 12 powder in the powder feeding cylinder, and place the copper powder in the powder feeding nozzle of the coaxial suction powder feeding mechanism with dual nozzles, wherein the nylon 12 powder is prepared by solvent precipitation method, and the particle size range is 10-30 μm. Copper powder is produced by gas atomization, the particle size range is 20-40μm, and both powders maintain good sphericity. Th...

Embodiment 3

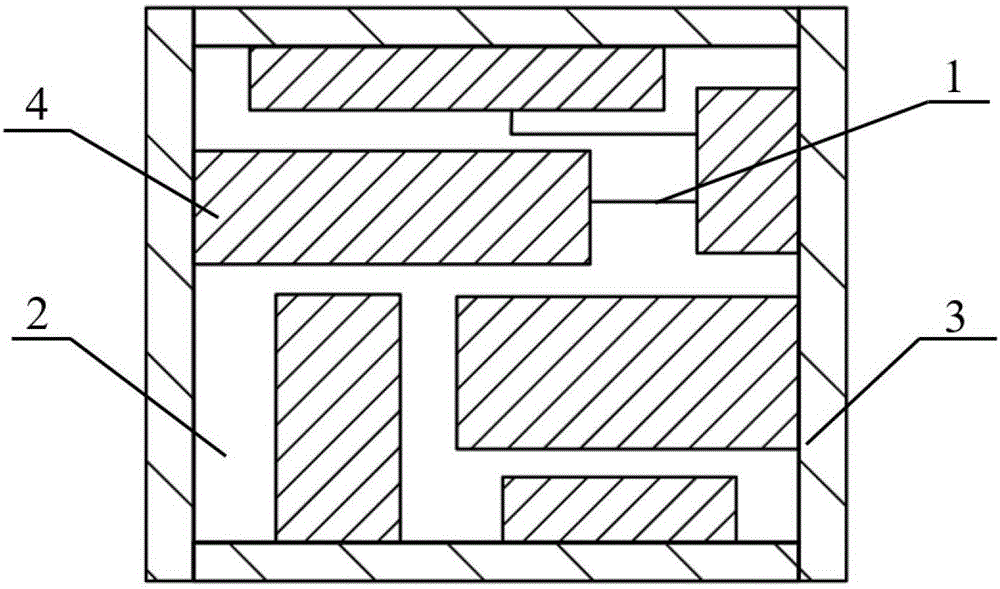

[0062] (1) Use 3D modeling software to design such as figure 2The structural model of the embedded four-sided circuit board is shown, in which 1 is the conductive circuit, 2 is the insulating substrate, 3 is the outer insulating board, and 4 is the electronic component. Import the model file into the SLS / SLM forming device, and use the system slicing software Carry out layered slices of the model, each layer thickness is 0.03mm, and obtain data information about the insulating substrate area, conductive line area and groove area in each layered slice;

[0063] (2) Nylon 12 powder is placed in the powder delivery tank, and copper-tin alloy powder is placed in the powder delivery nozzle of the coaxial suction powder delivery mechanism with dual nozzles. Nylon 12 powder is prepared by solvent precipitation method, and the particle size range is 15-35 μm , Copper powder is produced by gas atomization, the particle size range is 20-40μm, and both powders maintain good sphericity. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com