Antiwear nickel phosphor functionalized gradient plate preparation method

A functional gradient, wear-resistant nickel-phosphorus technology, applied in the field of preparation of wear-resistant nickel-phosphorus functionally gradient coatings, can solve the problems of reducing wear resistance, difficulty in achieving sufficient strength of the interface, and limiting the practical application of nickel-phosphorus alloy coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

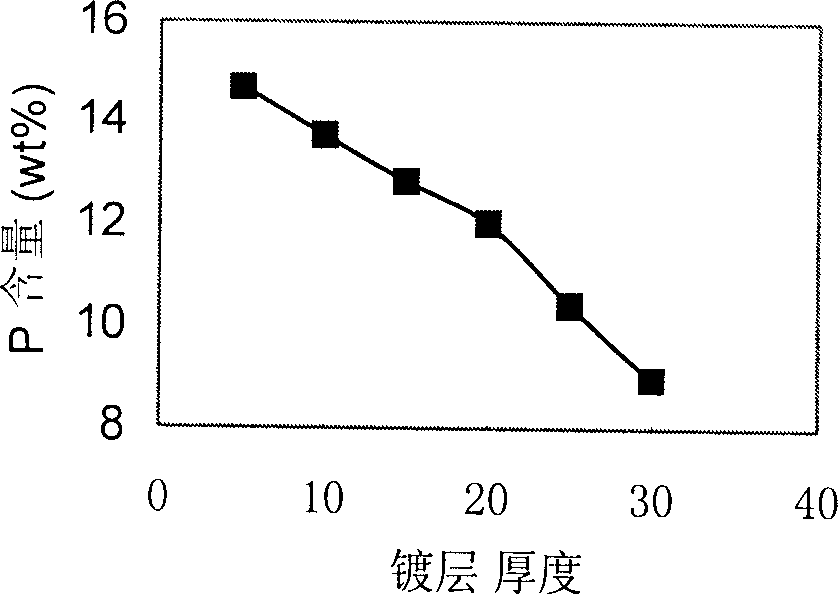

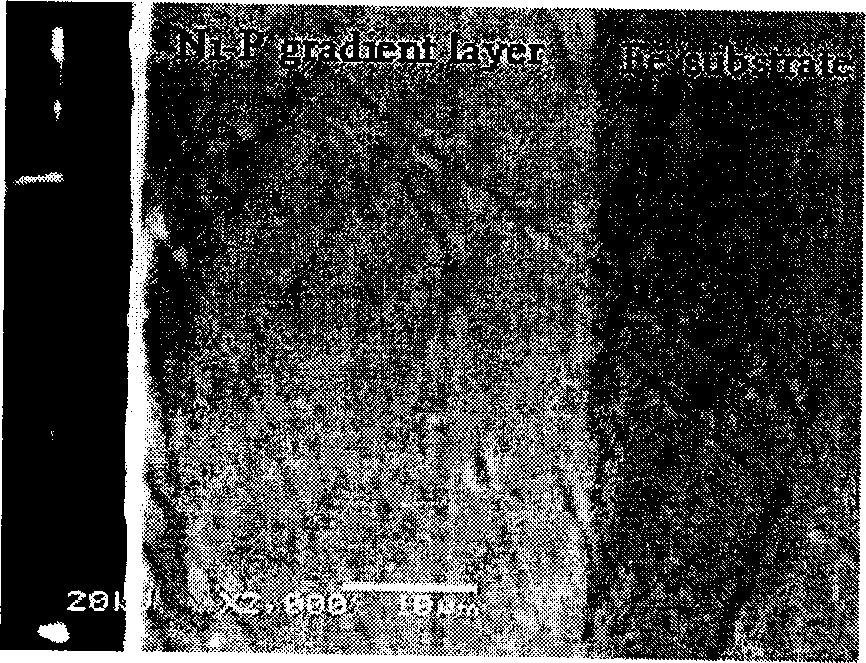

[0021] The wear-resistant nickel-phosphorus functional gradient coating is prepared by electroplating, using a controllable current DC power supply. The pure nickel sheet is used as the anode during electroplating, and the steel workpiece after conventional pre-plating pretreatment is used as the cathode. The electrolyte composition of the electroplating nickel-phosphorus gradient coating is as follows: the concentration of nickel sulfate is 240g / L, nickel chloride is 30g / L, boric acid 30g / L, phosphorous acid 20g / L. Adjust the pH value of the plating solution at 1.5, and keep the temperature within the range of 65-70°C. In the above-mentioned plating solution, use dilute hydrochloric acid to adjust the pH value of the plating solution during the electroplating process to be constant, and control the current density and corresponding A functionally graded coating of amorphous nickel-phosphorus alloy with a thickness of more than 30 μm can be deposited within a short electrodepo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com