An optimized process for improving the corrosion resistance of Zrcunialti bulk metallic glasses

A technology of corrosion resistance and bulk metal, which is applied in the optimization process field of improving the corrosion resistance of ZrCuNiAlTi bulk metallic glass, and can solve problems that have not been reported yet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

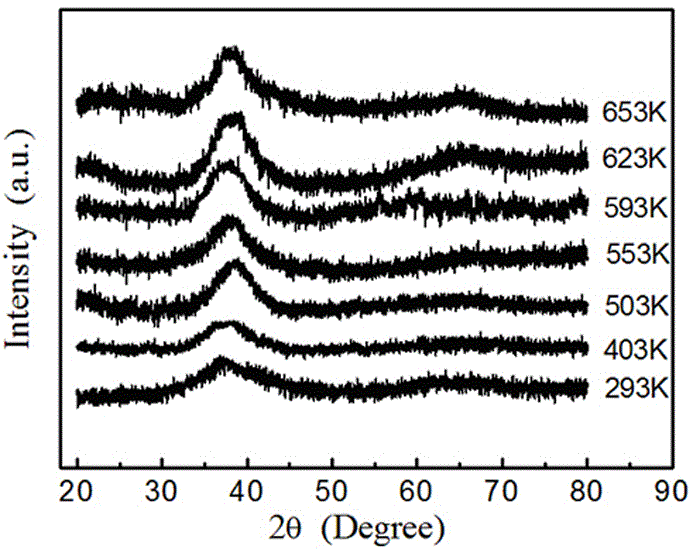

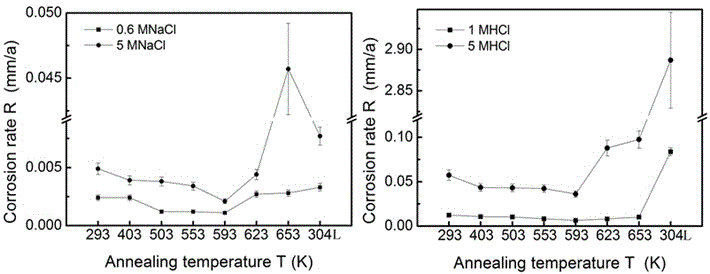

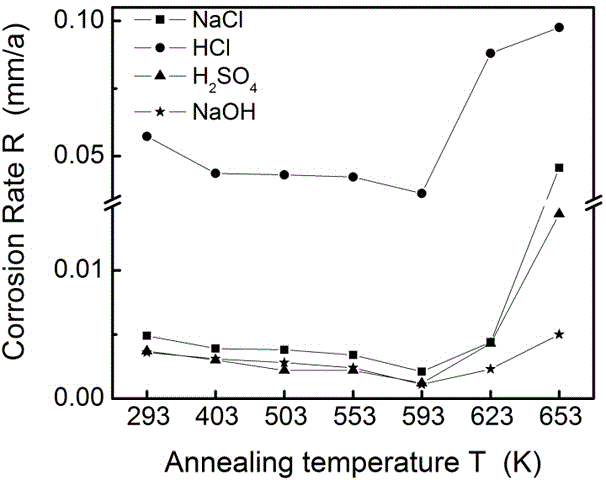

[0034] The present invention is described in detail below in conjunction with accompanying drawing as follows:

[0035] The present invention uses high-purity metal elements Zr, Cu, Al, Ni and Ti as raw materials to prepare Zr 52.5 Cu 17.9 Ni 14.6 al 10 Ti 5 Metallic glass master alloy, the purity of each batching element is as shown in Table 1:

[0036] Table 1. Preparation of Zr 52.5 Cu 17.9 al 10 Ni 14.6 Ti 5 Purity of components selected for master alloy ingot (wt.%)

[0037] alloy element

Zr

Cu

Al

Ni

Ti

Elemental purity%

99.99

99.99

99.99

99.99

99.999

[0038] The prepared raw material (30g) is put into the copper crucible in the smelting chamber, and the smelting chamber is vacuumed to 10 -3 Pa below and pass through argon for protection. The pure titanium ingots were smelted 2-3 times before the arc smelting samples to further consume the remaining oxygen in the chamber to prevent the oxidation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com