Optical glass detergent

A technology of optical glass and cleaning agent, which is applied in the direction of detergent compounding agent, detergent composition, surface active detergent composition, etc., can solve the problems of increasing the cost of use, affecting the quality of processing, and rapid rise of turbidity, etc., to achieve The effect of prolonging the use time, improving production efficiency and reducing cleaning costs

Active Publication Date: 2019-04-05

KUNSHAN CITY BANMING ELECTRONICS SCI & TECH

View PDF5 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There are still some problems in the actual cleaning of the above-mentioned production line using immersion cleaning: if the immersion time is short, it is difficult to clean the stubborn stains on the surface of the optical glass, and the rewash rate is high; if the immersion time is long, it is easy to produce slight scratches, The glass surface is hairy and foggy, which affects the quality

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

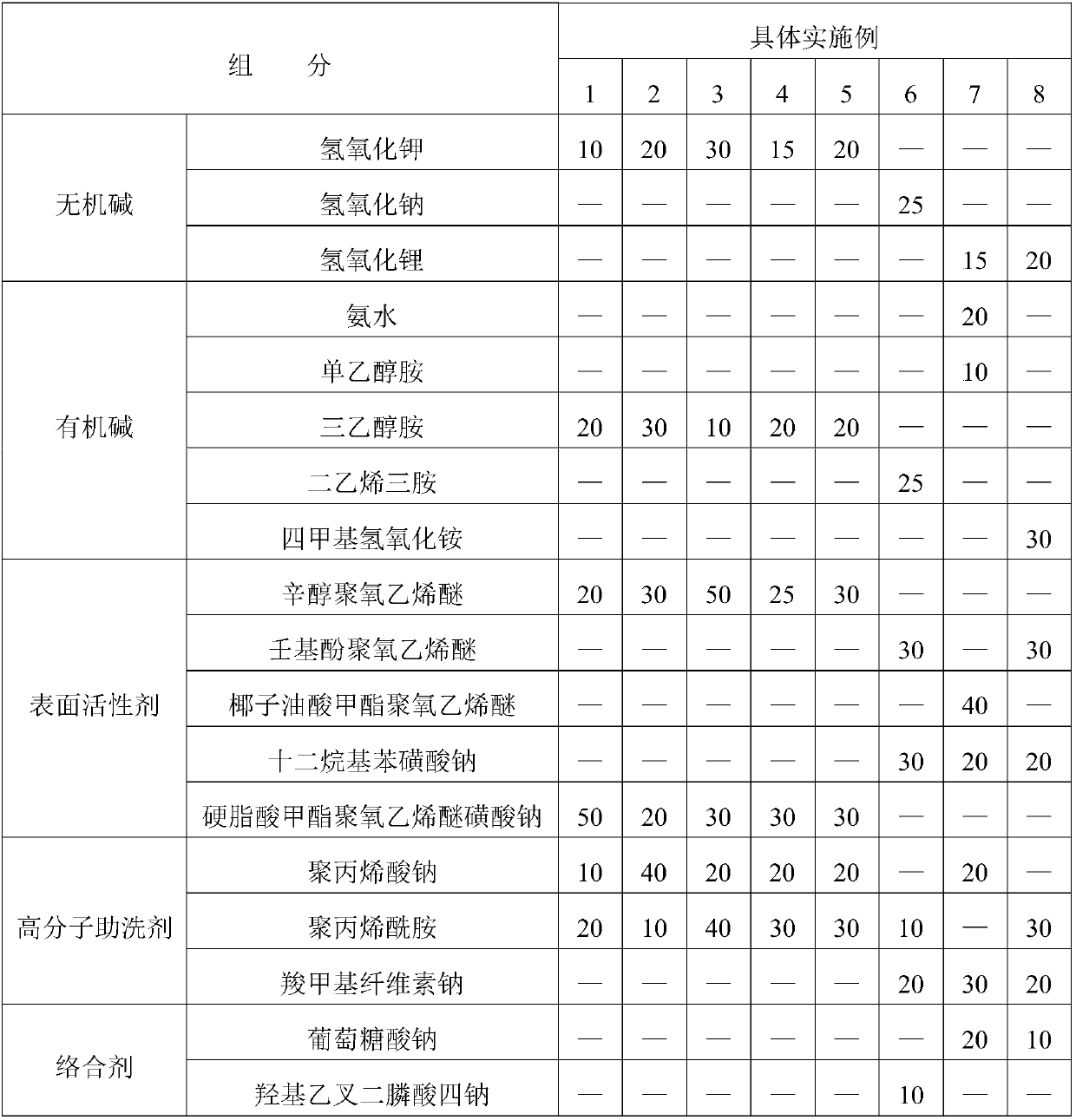

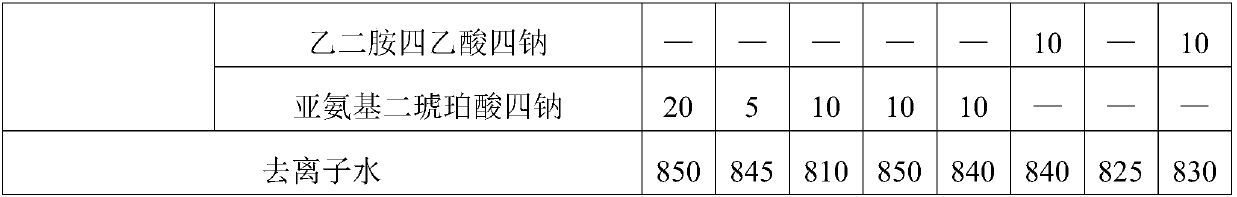

The invention discloses optical glass detergent. The optical glass detergent consists of inorganic alkali, organic alkali, compound surfactant, polymer builder, a complexing agent and deionized water,wherein the compound surfactant is obtained by mixing and compounding nonionic surfactant and anionic surfactant according to a certain mass ratio, and the polymer builder is at least one of sodium polyacrylate, polyacrylamide, sodium carboxymethyl cellulose and polyethylene glycol. The cleaning agent has the advantages of high decontamination capability, no glass corrosion and slow turbidity rising speed of the cleaning solution by virtue of the cooperative use of different surfactants as well as the reasonable matching of the components and the polymer builder, can quickly and effectively clean various pollutants on the surface of the glass, does not affect the quality of glass to be processed subsequently, does not affect the plugging-unplugging operation of the glass, prolongs the service life of the cleaning solution, improves the production efficiency and reduces the cleaning cost.

Description

technical field [0001] The invention relates to a glass cleaning agent, in particular to an optical glass cleaning agent, and belongs to the technical field of cleaning agent products for electronic equipment. Background technique [0002] With the vigorous development of intelligent electronic equipment, the application of optical glass in the field of optoelectronic display is advancing by leaps and bounds, especially the domestic optical glass manufacturing industry has a good growth momentum. Grinding and polishing in the production of optical glass will result in residual contaminants such as abrasive powder, polishing liquid, fingerprints, dust, and oil stains on the glass surface. Therefore, the cleaning process is essential, and it is required to clean the surface without residues. No scratches, no hair and fog, so as not to affect the quality of subsequent processing such as coating and silk screen printing. [0003] At present, most of the optical glass cleaning m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C11D1/831C11D1/825C11D3/04C11D3/30C11D3/37C11D3/22C11D3/36C11D3/33C11D3/60

CPCC11D1/008C11D1/22C11D1/72C11D1/74C11D1/825C11D1/831C11D3/044C11D3/221C11D3/225C11D3/30C11D3/33C11D3/365C11D3/3765C11D3/3773

Inventor 王立中黄志齐陈修宁黄京华王淑萍李晨庆

Owner KUNSHAN CITY BANMING ELECTRONICS SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com