Sewage disposal device

A technology for cleaning and supporting pipes, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as dust contamination of power supply equipment, tripping of equipment pollution flashover lines, dust pollution of power supply facilities, etc. Achieve the effect of meeting the needs of cleaning or fire extinguishing, solving circuit failures or accidents, and quick and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

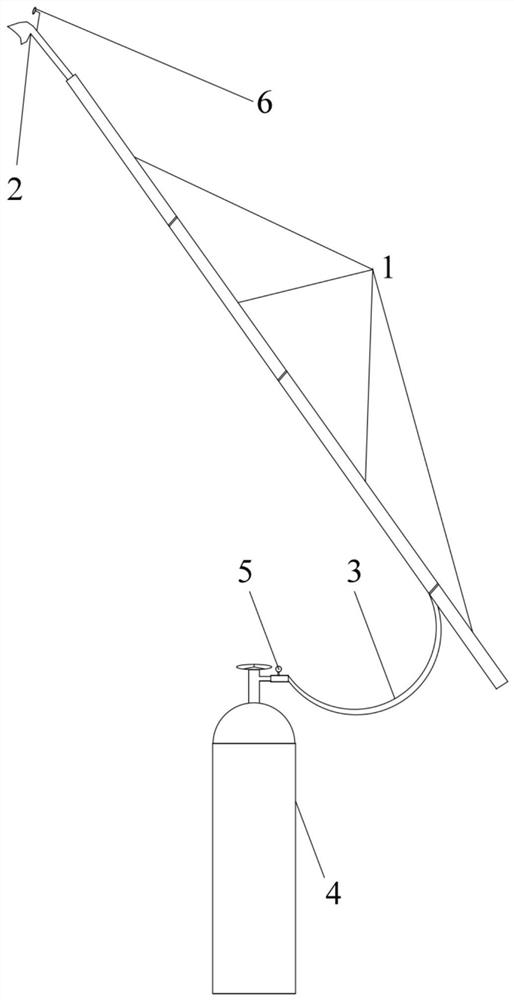

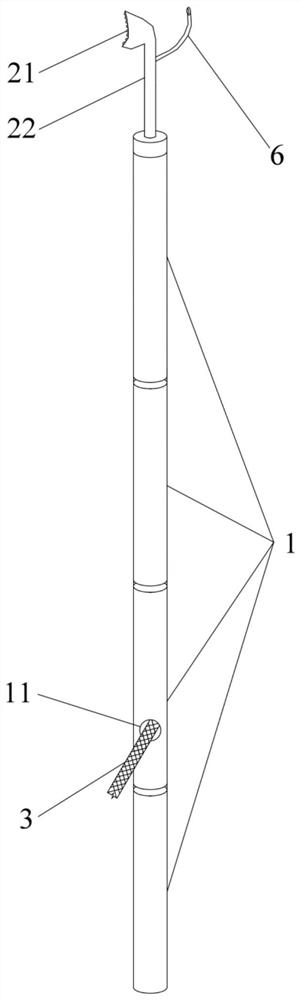

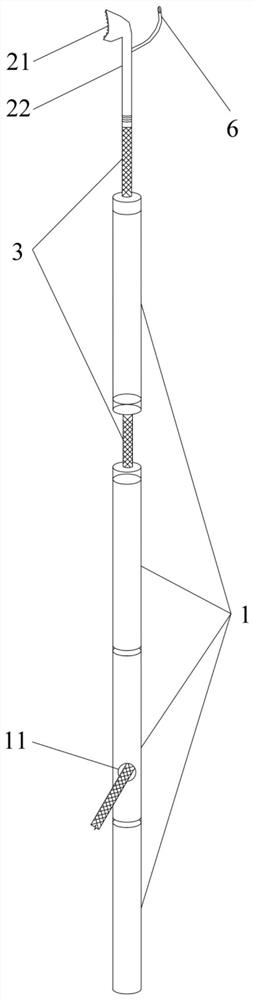

[0040] see Figure 1 to Figure 5 , the present embodiment provides a cleaning device, including a support rod, a nozzle 2, a pressure pipe 3 and a pressure gas cylinder 4, wherein the support rod is formed by sequentially connecting a plurality of support pipes 1 in the axial direction, and one end of the support rod serves as an operating One end is used to set the nozzle 2, the other end is used as the working end for the operator to hold, the nozzle 2 is detachably connected to the support tube 1 at the working end of the support rod, the pressure pipe 3 is in the support rod, and one end is connected to the nozzle 2 , the other end passes through the support rod and is connected to the pressure gas cylinder 4.

[0041] In the above arrangement, a plurality of support tubes 1 are combined to form a firm support rod structure. The nozzle 2 is installed and disassembled on the support tube 1 at the working end of the support rod. A pressure pipe 3 is pierced inside the suppor...

Embodiment 2

[0057] The second embodiment discloses a cleaning device whose structure is basically the same as that of the first embodiment. The cleaning device includes a support rod, a nozzle 2, a pressure pipe 3, a pressure gas cylinder 4, a pressure valve 5 and a camera 6, and the support rod is composed of a plurality of support pipes 1 to form a firm support structure. The support pipe 1 at the working end of the support rod The spray head 2 is installed and disassembled on the top, and the support rod composed of a plurality of support pipes 1 is pierced with a pressure pipe 3, one end of the pressure pipe 3 is connected to the spray head 2, and the other end is connected to the pressure cylinder 4 through the pressure valve 5, and the camera 6 It is detachably installed on the nozzle 2. The configuration of the above structures, the specific structures further included and their connection methods are the same as those in the first embodiment.

[0058] see Figure 1 to Figure 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com