Preparation method for compact zirconite overflow brick with high breaking-resistance and low expansion

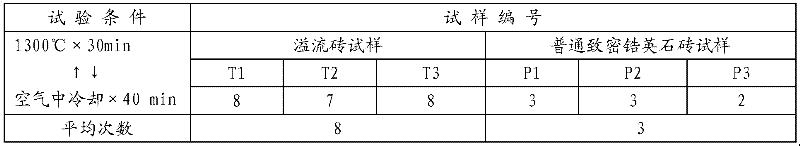

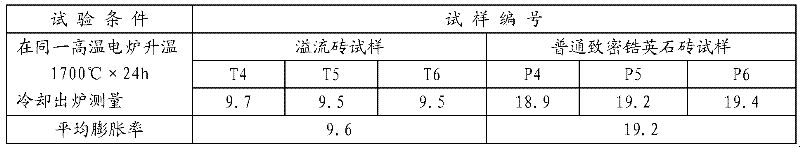

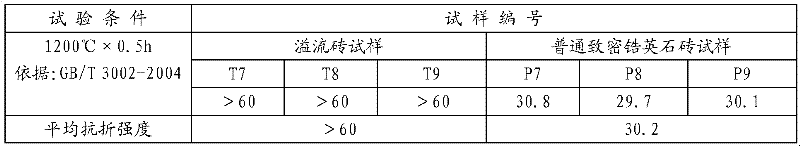

A zircon and low-expansion technology, applied in the field of preparation of dense zircon overflow bricks, can solve problems affecting the quality of liquid crystal glass overflow bricks, service life, production difficulties, and easy cracks, etc., to achieve enhanced resistance to glass erosion performance, improving thermal shock resistance, and improving the effect of flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: The overflow brick prepared by the present invention is a large and special-shaped product, and has very strict requirements on physical and chemical performance indicators. The present invention uses full clinker production, and a specific molding system and firing system. So as to ensure product quality.

[0033] The steps for preparing dense zircon overflow bricks with a length of 3150-6000mm, a width of 1020-1600mm, and a thickness of 260-1000mm are as follows:

[0034] (1) Use ZrSiO 4 ≥98.5% zircon sand is used as the starting material, and its chemical composition and weight content percentage are: ZrSiO 4 : 98.62-98.73%; TiO 2 : 0.15-0.21%; Fe 2 o 3 : 0.18-0.23%; R 2 O(Na 2 O+K 2 O): 0.17-0.25%; RO (CaO+MgO): 0.15-0.25%; content of volatile substances and organic substances: 0.5-0.8%.

[0035] (2) Pickling the above-mentioned zircon sand: adding the zircon sand to a hydrochloric acid solution with a concentration of 10-15% (mass ratio) for pick...

Embodiment 2

[0065] Embodiment 2: Repeat Example 1, the difference is only that in the step (4) the zircon sand qualified for calcining is ground in the stirring mill according to the following weight formula ratio: zircon sand 99.2%; TiO 2 0.7%; phosphoric acid 0.1%.

Embodiment 3

[0066] Embodiment 3: Repeat Example 1, the difference is only that in the step (4) the zircon sand qualified for calcining is ground in the stirring mill according to the following weight formula ratio: zircon sand 99.0%; TiO 2 0.8%; phosphoric acid 0.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com