Corrosion-preventing processing method for pipe end of inner lining glass corrosion-preventing steel pipe

A technology of anti-corrosion steel pipe and treatment method, which is applied in the field of steel pipe manufacturing, can solve the problems of poor corrosion resistance of the inner surface of the weld, and achieve the effect of anti-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention will be further described below in conjunction with the accompanying drawings and specific examples, but not as a limitation of the invention.

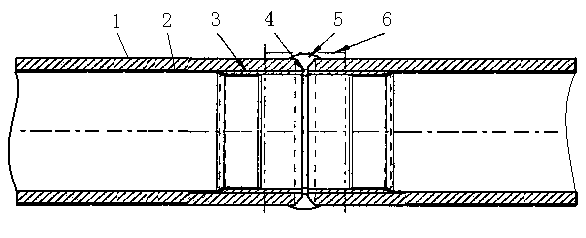

[0015] see figure 1 , before the sandblasting pretreatment in the steel pipe, use an automatic surfacing welding machine to pre-surfacing the nickel-based corrosion-resistant alloy layer 3 on the end face of the steel pipe 1 to a depth of 30-50 mm (the nickel-based corrosion-resistant alloy layer 3 is preferably Ni-Cr -Mo), with a thickness of 1.5-2 mm, which is melted on the base metal to obtain the corrosion resistance of the surfacing layer of the nozzle.

[0016] The surface of the surfacing layer is cleaned, the steel pipe is sandblasted to remove rust and purge, and then the inner anti-corrosion layer 2 of the glass is deposited; the inner anti-corrosion layer 2 of the glass covers the nickel-based corrosion-resistant alloy layer 3, and a 15-25mm welding heat-affected zone is reserved 6 .

[0017] During t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com