Lead-free glass powder, lead-free glass powder slurry, large-area dye-sensitized solar cell as well as preparation method and application thereof

A lead-free glass powder and solar cell technology, applied in the field of solar cells, can solve the problems of packaging materials affecting battery life, easy precipitation of glass powder slurry, easy leakage of electrolyte, etc., to prevent agglomeration and precipitation, and reduce the number of holes , The effect of volatile removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

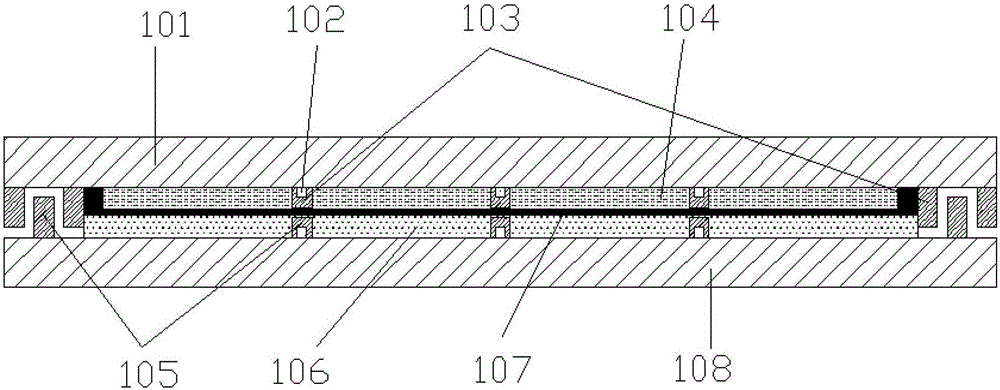

[0052] Such as figure 1 Shown, lead-free glass powder, including the following components: SiO 2 12%, B 2 o 3 6%, Bi 2 o 3 65%, ZnO5%, Al 2 o 3 5%, Na 2 O 1%, BaO 3% and CaO 3%.

[0053] The preparation method of the lead-free glass powder comprises the following steps: weighing each component of the lead-free glass powder according to the above weight, after mixing, smelting in a lifting furnace at 1300°C for 30 minutes to obtain molten glass, and then quenching the molten glass Finally, dry the small glass particles, and finally ball mill the small glass particles in a planetary high-energy ball mill with a ball-to-material ratio of 3:1 and a rotation speed of 450-500 rpm for 8-10 hours to obtain low-melting point glass powder. Then sieve to obtain ultra-fine glass powder with a particle size of glass powder below 5 μm. After testing, the softening point of the lead-free glass powder of the present invention is between 425°C and 480°C, and the coefficient of lin...

Embodiment 2

[0077] Such as figure 1 Shown, lead-free glass powder, including the following components: SiO 2 20%, B 2 o 3 15%, Bi 2 o 3 40%, ZnO10%, Al 2 o 3 10%, Na 2 O 2%, BaO 1%, and CaO 2%.

[0078] The preparation method of lead-free glass powder comprises the following steps: weighing each component of lead-free glass powder according to the above weight, after mixing, smelting in a lifting furnace at 1000°C for 10 minutes to obtain molten glass, and then quenching the molten glass Finally, dry the small glass particles, and finally ball mill the small glass particles in a planetary high-energy ball mill with a ball-to-material ratio of 3:1 and a rotation speed of 450 rpm for 10 hours to obtain low-melting point glass powder. Then sieve to obtain ultra-fine glass powder with a particle size of glass powder below 5 μm. After testing, the softening point of the lead-free glass powder of the present invention is between 425°C and 480°C, and the coefficient of linear expansi...

Embodiment 3

[0101] Such as figure 1 Shown, lead-free glass powder, including the following components: SiO 2 10%, B 2 o 3 5%, Bi 2 o 3 70%, ZnO1%, Ai 2 o 3 1%, Na 2 O 1%, BaO 5% and CaO 7%.

[0102] The preparation method of lead-free glass powder comprises the following steps: weighing each component of lead-free glass powder according to the above weight, after mixing, smelting in a lifting furnace at 1500°C for 20 minutes to obtain molten glass, and then quenching the molten glass Finally, dry the glass particles to obtain small glass particles, and finally ball mill the small glass particles in a planetary high-energy ball mill with a ball-to-material ratio of 3:1 and a rotation speed of 500 rpm for 8 hours to obtain low-melting point glass powder. Then sieve to obtain ultra-fine glass powder with a particle size of glass powder below 5 μm. After testing, the softening point of the lead-free glass powder of the present invention is between 425°C and 480°C, and the coeffic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com