Fluorescent carbon quantum dot as well as preparation method and application thereof

A technology of carbon quantum dots and fluorescence quantum yield, applied in the direction of fluorescence/phosphorescence, chemical instruments and methods, luminescent materials, etc., can solve the problems of high cost, low fluorescence quantum yield, unfavorable continuous and large-scale production of carbon quantum dots, etc. , to achieve the effect of convenient operation, high fluorescence quantum yield and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1, weigh 0.5g of oxalic acid and 0.5g of urea in a microwave-resistant container, then add 10mL of secondary water, stir well, and ultrasonically obtain a clear solution;

[0037] Step 2, the microwave-resistant container is placed in a microwave oven (800 watts) and reacted for 8 minutes under high heat to obtain a light yellow solid;

[0038] Step 3, take out the microwave-resistant container, cool it naturally, add 10mL of secondary water into it, stir and dissolve to obtain a light yellow solution, filter and remove insoluble matter to obtain a clear light yellow solution, remove impurities by dialysis, and obtain pure fluorescent carbon quantum dots aqueous solution;

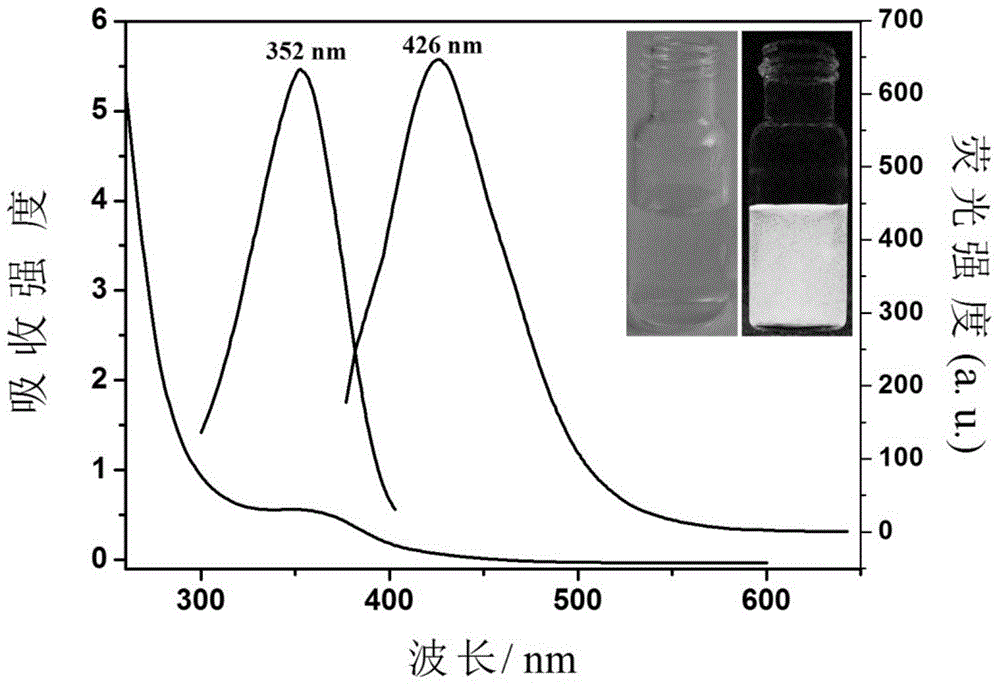

[0039] In step 4, the fluorescent carbon quantum dot aqueous solution is freeze-dried to obtain the fluorescent carbon quantum dot, and its relative quantum yield (using quinine sulfate as a standard) is 28.7%.

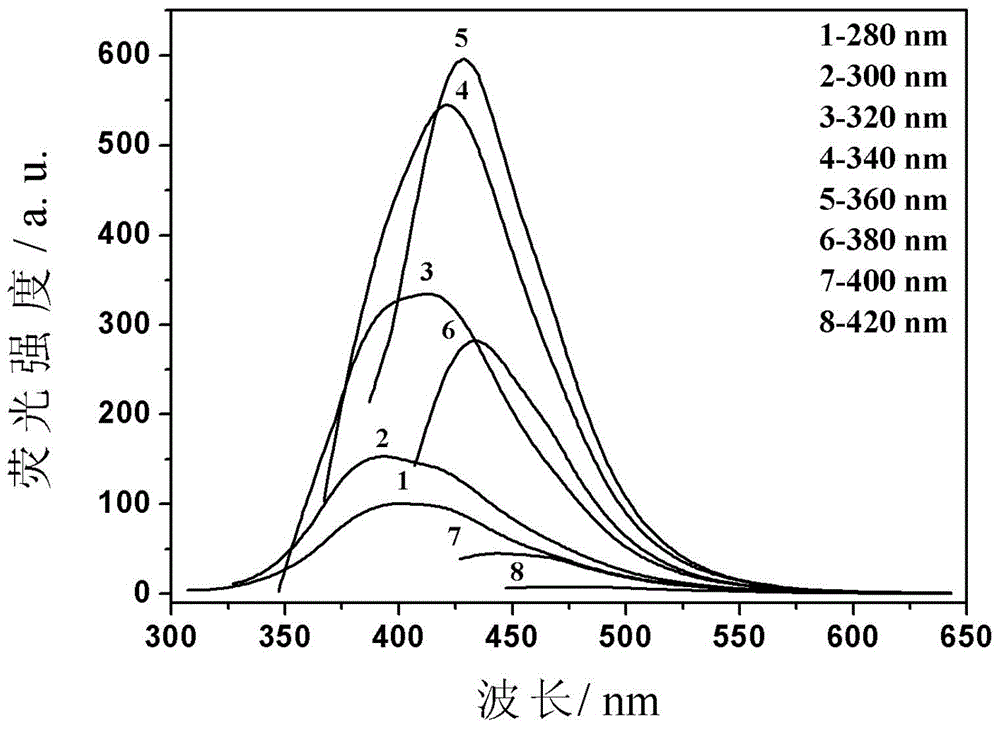

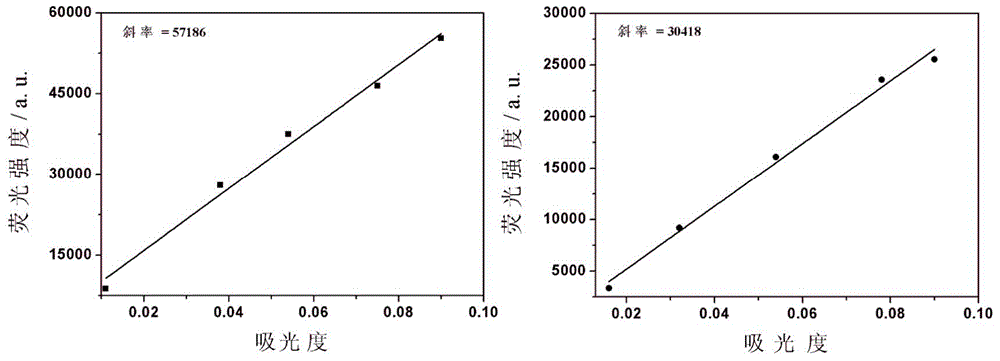

[0040] Characterization and application see Figure 1-13 .

Embodiment 2

[0042] Step 1, weigh 0.5g of oxalic acid and 0.8g of urea in a microwave-resistant container, then add 13mL of secondary water, stir well, and ultrasonically obtain a clear solution;

[0043] Step 2, the microwave-resistant container is placed in a microwave oven (800 watts) and reacted for 10 minutes under high heat to obtain a light yellow solid;

[0044] Step 3, take out the microwave-resistant container, cool naturally, add 14mL of secondary water to it, stir and dissolve to obtain a light yellow solution, filter and remove insoluble matter to obtain a clear light yellow solution, remove impurities by dialysis, and obtain pure fluorescent carbon quantum dots aqueous solution;

[0045] In step 4, the fluorescent carbon quantum dot aqueous solution is freeze-dried to obtain the fluorescent carbon quantum dot, and its relative quantum yield (taking quinine sulfate as a standard) is 25.7%.

Embodiment 3

[0047] Step 1, weigh 0.8g oxalic acid and 0.5g urea in a microwave-resistant container, then add 14mL of secondary water, stir well, and ultrasonically obtain a clear solution;

[0048] Step 2, the microwave-resistant container was placed in a microwave oven (800 watts) and reacted for 11 minutes at high heat to obtain a light yellow solid;

[0049] Step 3, take out the microwave-resistant container, cool it naturally, add 15mL of secondary water into it, stir and dissolve to obtain a light yellow solution, filter and remove insoluble matter to obtain a clear light yellow solution, remove impurities by dialysis, and obtain pure fluorescent carbon quantum dots aqueous solution;

[0050]In step 4, the fluorescent carbon quantum dot aqueous solution is freeze-dried to obtain the fluorescent carbon quantum dot, and its relative quantum yield (using quinine sulfate as a standard) is 22.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com