Preparation of aluminum or aluminum alloy dual-layer anodic oxide film and preparation of multi-color coloring film thereof

A technology of anodic oxidation film and aluminum alloy, applied in the direction of coating, surface reaction electrolytic coating, electrolytic coating, etc., can solve problems such as difficult technology, complicated process, and difficult to master in actual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Pretreatment: use 250g / L NaOH, 460g / L NaNO 3 , 1g / L CoSO 4 The composed chemical polishing solution is used to chemically polish the sample. The temperature is 80-95°C, and the time is 10-20s. Aluminum samples were rinsed repeatedly with deionized water after polishing.

[0027] 2) Anodizing: take 3 pretreated aluminum samples and carry out anodizing treatment respectively. The bath composition is 184g / L H 2 SO 4 and 1g / LAl 2 (SO 4 ) 3 . At room temperature (20-25°C), first use DC 1A / dm 2 Oxidize for 20min, and then use a sine wave asymmetric alternating current in the same anodizing tank (the average current density of the anode is 1.5A / dm 2 , the ratio of the average current density of the anode to the average current density of the cathode is 3:1) respectively oxidized for 10 min, 15 min or 20 min to obtain double-layer anodized films with different AC film thicknesses.

[0028] 3) Electrolytic coloring: the above three double-layer anodized films are a...

Embodiment 2

[0031] 1) Mechanical pretreatment: use sandblasting or sandpaper grinding to remove foreign matter such as burrs, firm oxides, lubricants for extrusion, cutting oil, etc., reduce surface roughness, and wash with water.

[0032] 2) Chemical polishing: use 300g / L NaOH, 500g / L NaNO 3 , 2g / L CoSO 4 The composed chemical polishing solution is used to chemically polish the sample. Temperature 80~95℃, time 10-20s, wash with water.

[0033] 3) Anodizing: take 3 pre-treated aluminum samples and carry out anodizing treatment respectively. The bath composition is 184g / L H 2 SO 4 and 8g / L H 2 C 2 o 4 . At room temperature, adopt symmetrical sine wave AC 1A / dm 2 Oxidize for 10min, 15min or 20min respectively. During the oxidation process, the voltage rises from 21V to 23V. Then use DC 1.5A / m in the same anodizing tank 2 Oxidation for 15min. A double-layer anodized film whose outer layer is a common AC film and whose inner layer is a DC film is obtained.

[0034] 4) Electrolyti...

Embodiment 3

[0037] 1) Mechanical pretreatment: Sandblasting and sandpaper grinding are used to remove foreign matter such as burrs, firm oxides, lubricants for extrusion, cutting oil, etc., and reduce surface roughness. wash.

[0038] 2) Chemical polishing: use 300g / L NaOH, 520g / L NaNO 3 , 5g / L CoSO 4 The composed chemical polishing solution is used to chemically polish the sample. The temperature is 80-95°C, and the time is 10-20s. wash.

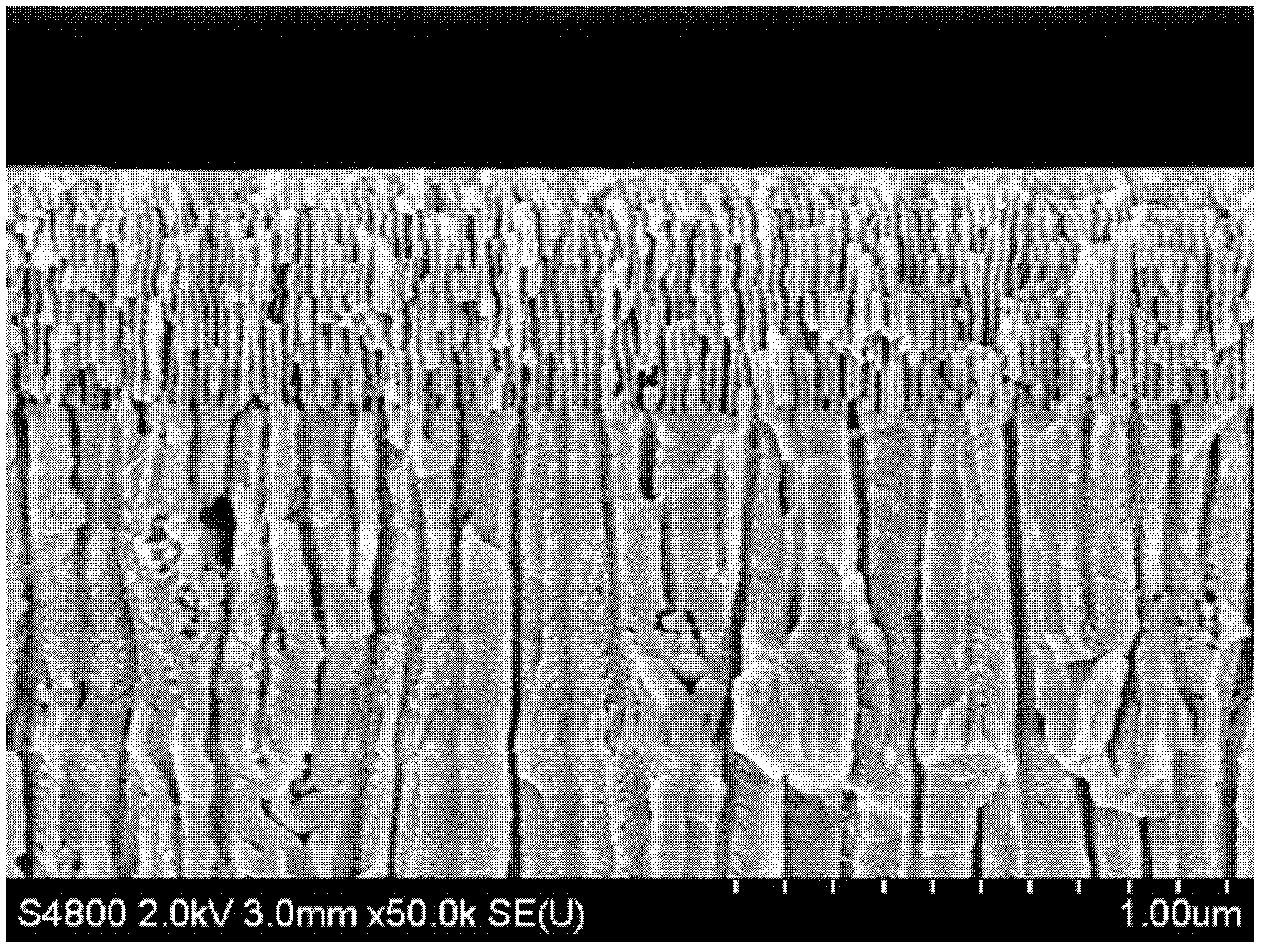

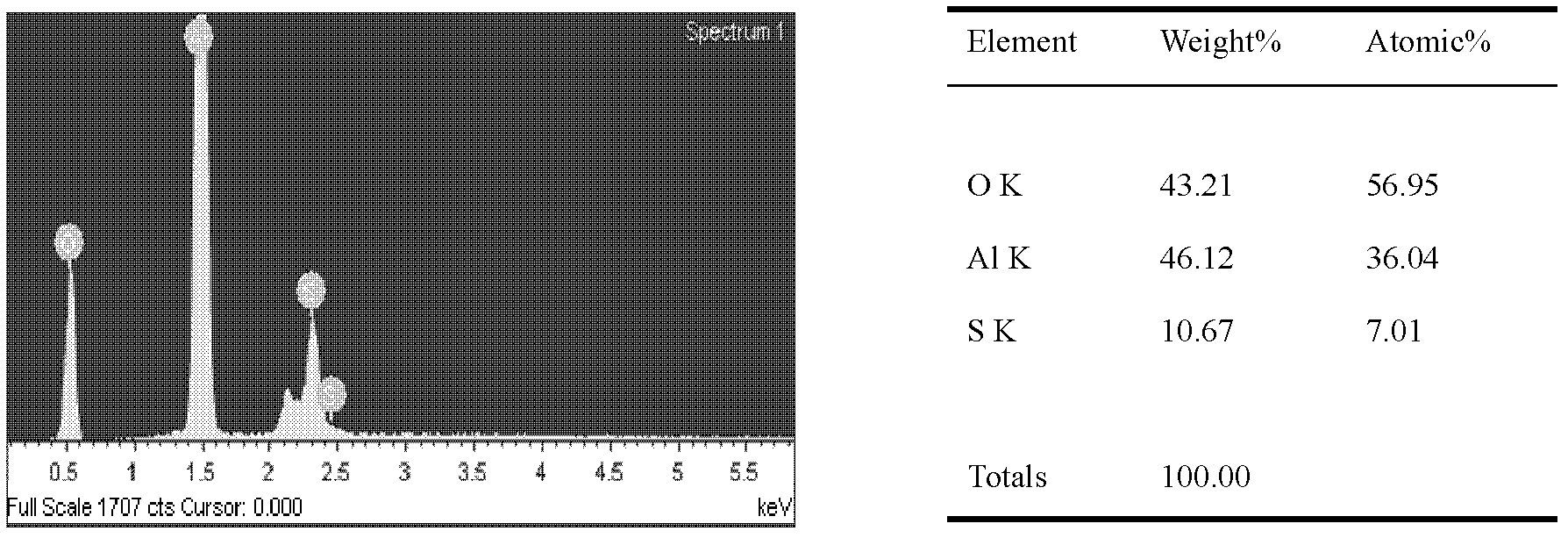

[0039] 3) Anodizing: take 3 pre-treated samples for anodizing treatment. The bath composition is 184g / LH 2 SO 4 and 1g / LAl 2 (SO 4 ) 3 . At room temperature, using pulsed DC 2A / dm 2 , The working ratio is 80%, respectively oxidized for 10min, 15min or 20min, and then in the same anodic oxidation tank, use a sine wave alternating current with a constant current of 1A / dm 2 Oxidize for 20 minutes to obtain a double-layer anodic oxidation film (wherein, the film layer structure and elemental analysis of No. 3 test piece are shown in the attache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com