Aluminum strip continuous anodic oxidation automatic production line

An automatic production line, anodizing technology, applied in anodizing, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve the problem of time-consuming and labor-intensive, and achieve the effect of uniform and uniform products

Inactive Publication Date: 2010-03-24

浙江聚力文化发展股份有限公司

View PDF0 Cites 57 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to overcome the time-consuming and labor-intensive defect of manual operat

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

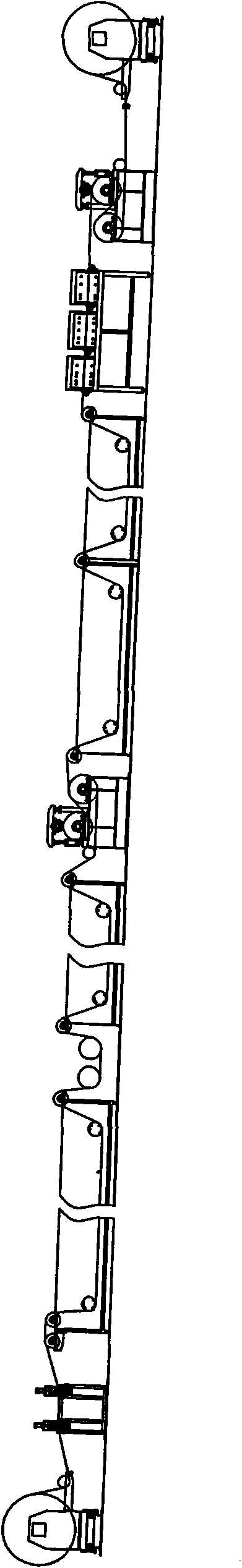

The invention belongs to the technical field of aluminum anodic oxidation treatment, and relates to an aluminum strip continuous anodic oxidation automatic production line which is characterized by comprising an unwinding machine, a splicing machine, not less than one driving machine and winding machine, and a transmission system that is formed by a conveyor belt and a transmission roller and usedfor transmitting aluminum sheets; furthermore, the production line also comprises a grease skimming tank, an acid-base etching tank, a neutralizing tank, an electric conduction roller, an oxidation tank, an electrolytic coloring tank, a chemical staining tank, a hole sealing groove and a drying box which are sequentially arranged correspondingly to the aluminum anodic oxidation technique; and atleast one rinsing bath used for cleaning is arranged among the working procedure processing tanks. The automatic production line can lead aluminum strip to be continuously processed by oxidation treatment, thus saving time and labor and being unified in the product performance.

Description

technical field [0001] The invention belongs to the technical field of anodic oxidation production of metal materials, and in particular relates to an automatic production line for continuous anodic oxidation of aluminum strips. Background technique [0002] Aluminum is one of the most widely used metal materials among non-ferrous metals. It has a series of powerful physical, chemical and processing properties, and it has a wide range of uses; high-tech products, high-end building decoration materials, transportation , aerospace, lighting and electronic products, etc. [0003] According to the different uses of aluminum materials, some properties are not ideal, such as surface properties such as hardness, wear resistance, and corrosion resistance. These properties can be processed by anodizing to expand the application range of aluminum materials and prolong service life. significance. [0004] In the prior art, the anodic oxidation of aluminum materials is all manually op...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C25D11/04C25D11/16C23G1/22

Inventor 姜飞雄

Owner 浙江聚力文化发展股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com