Method for preparing TiO2 nanotube array film

A nanotube array and thin film technology, which is applied in the field of nanotube thin film preparation, can solve the problems of nozzle agglomeration, thin nanotube array thin film layer, uneven nanotube length, etc. Appearance, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

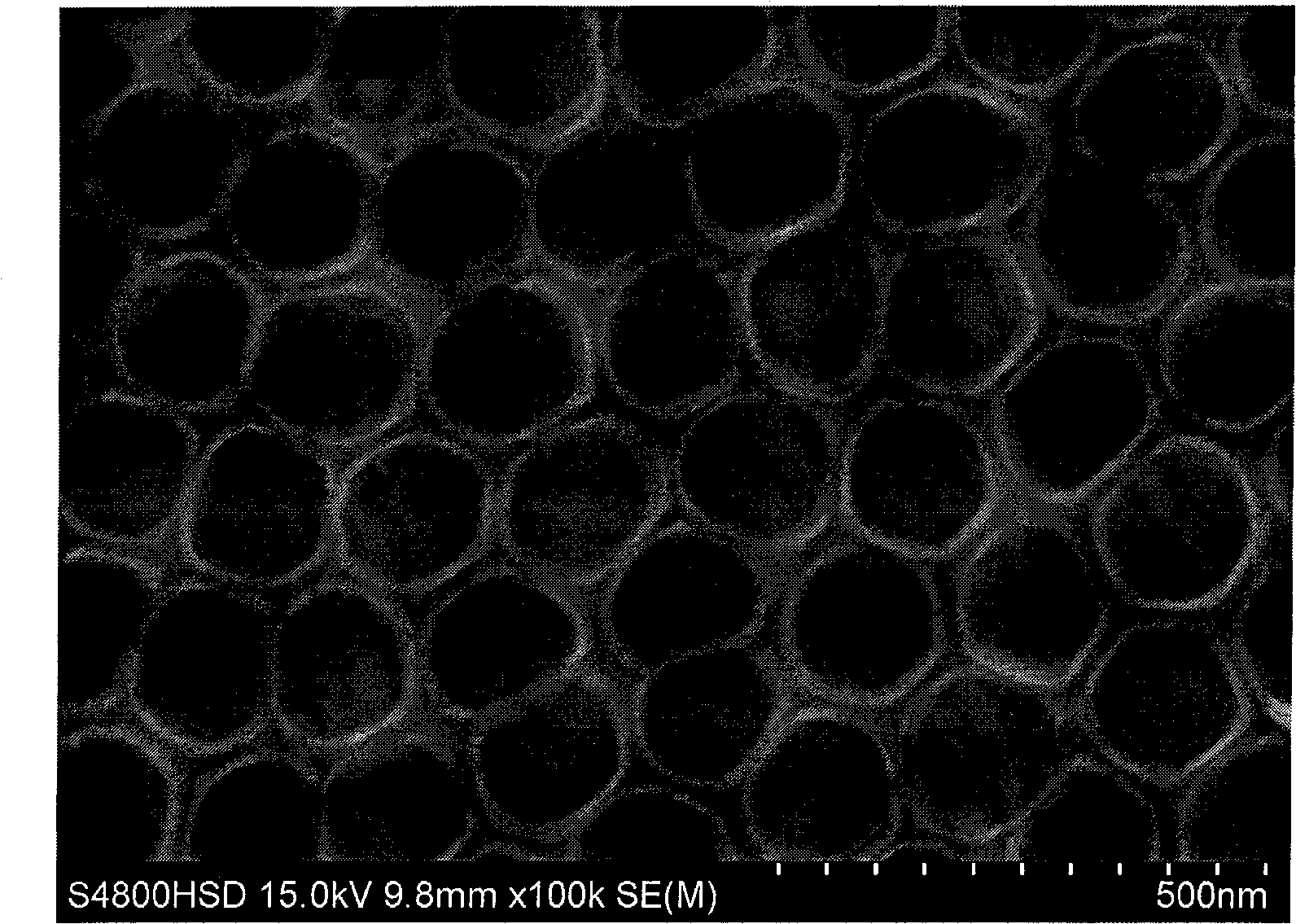

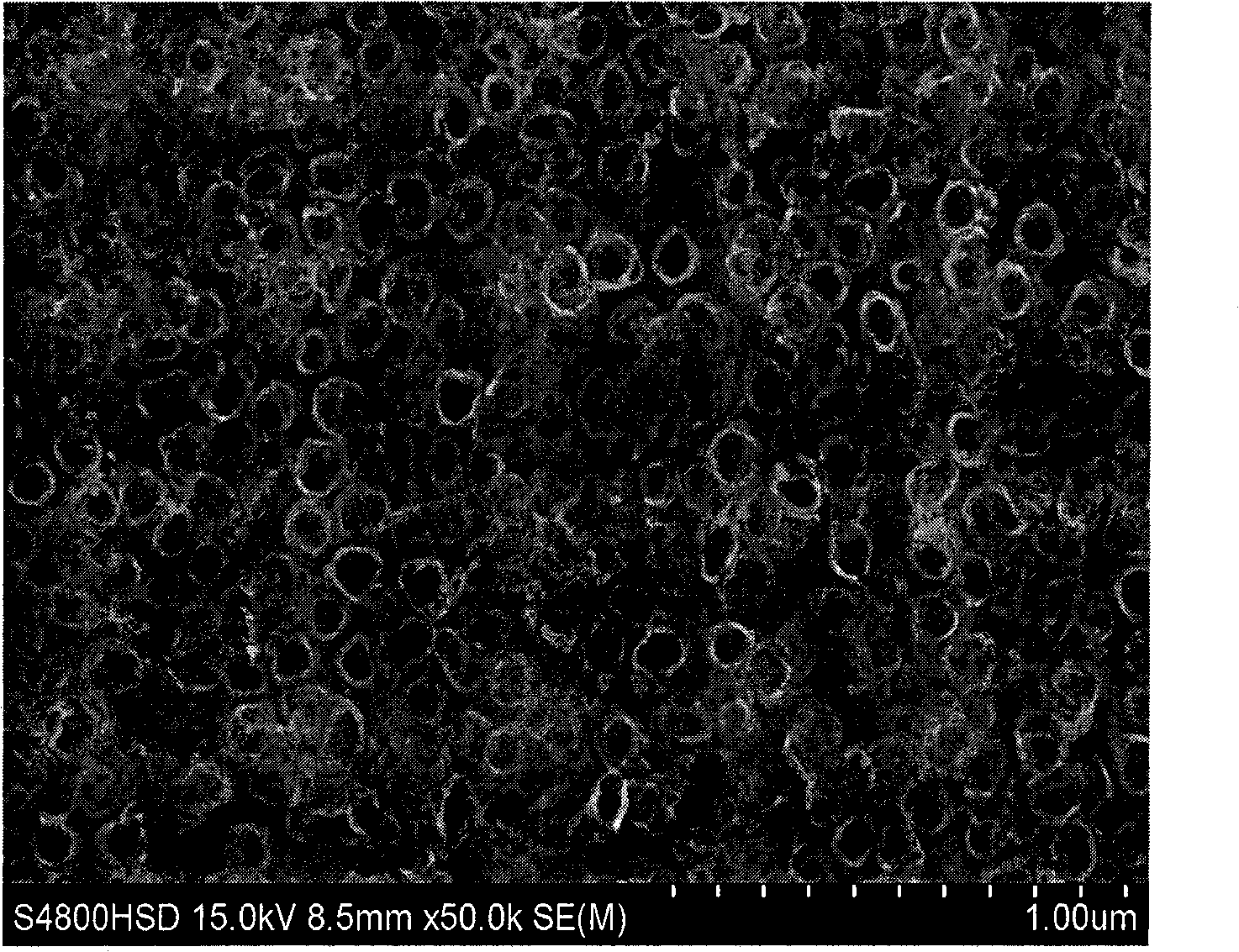

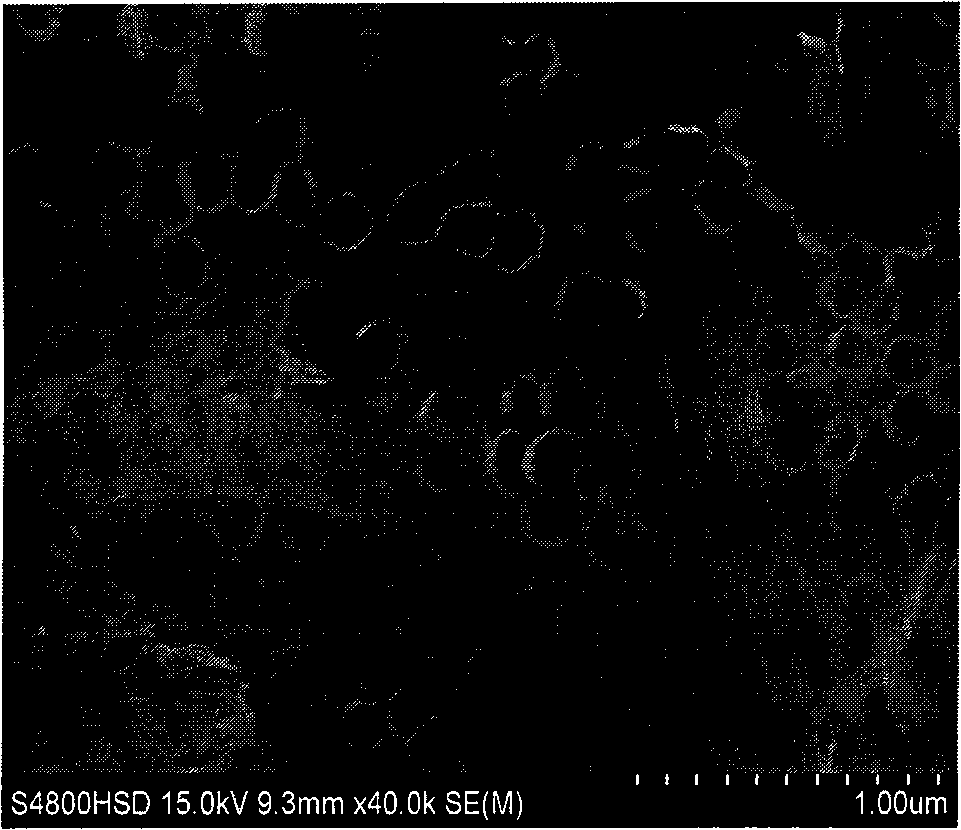

[0007] Specific implementation mode 1: TiO in this implementation mode 2 The preparation method of the nanotube array film is realized by the following steps: 1. Cut the titanium plate into two titanium sheets of the same size, then polish the two titanium sheets, and then put them into acetone for ultrasonic treatment for 10 to 60 minutes, and then wash them with distilled water Rinse 3 to 5 times; 2. Weigh 0.5 to 1.5 g of ammonium fluoride and dissolve it in 4 to 10 mL of distilled water, and then mix it with 100 to 200 mL of ethylene glycol or glycerol to obtain an electrolyte; 3. At room temperature, immerse the two titanium sheets treated in step 1 in the electrolyte solution prepared in step 2 in parallel, one is the anode and the other is the cathode, apply a voltage of 20-70V, and then electrolytically treat for 20-60 minutes; 1. Take out the titanium sheet used as the anode, put it into a dilute acid solution for ultrasonic treatment for 5-30 minutes, and then rinse i...

specific Embodiment approach 2

[0013] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the size of the two titanium sheets in step 1 is 25mm×10mm. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0014] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, the two titanium sheets are polished with 50-300Cw water-resistant sandpaper, 500-1000Cw water-resistant sandpaper and 1500-2500Cw water-resistant sandpaper respectively. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com