Preparation of illuminant color adjustable tricolor organic-inorganic silicon-based hybrid material

A technology of luminous color and three primary colors, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems such as the difficulty of hybrid materials, and achieve the effects of regular microscopic morphology, good reproducibility, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

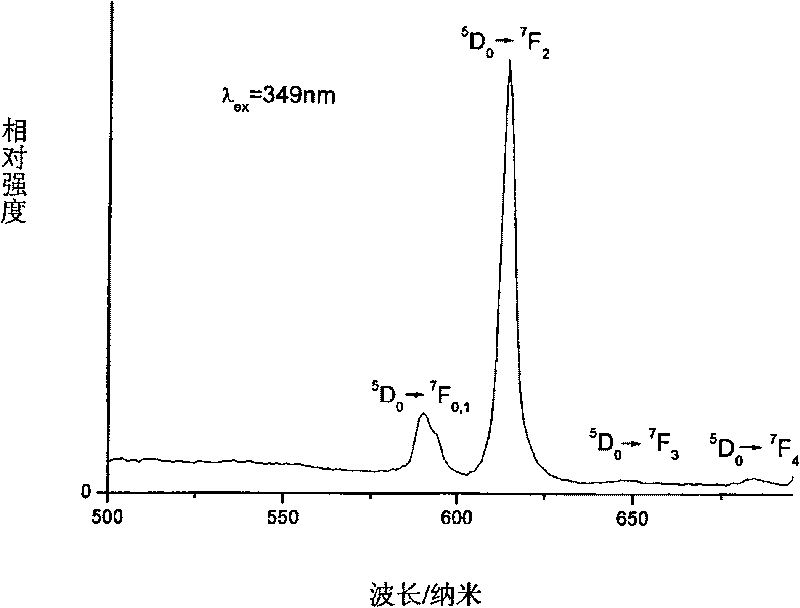

[0025] Dissolve 1 mmol of α-hydroxypyridine in 10 ml of DMF, add to a three-necked flask and heat to reflux. Then a solution of 0.8 mmol triethoxysilylisocyanopropyl isocyanate dissolved in 10 ml DMF was added dropwise. After the dropwise addition, the entire solution was refluxed at 80° C. for 6 h under the protection of nitrogen, cooled, and the solvent was distilled off under reduced pressure to obtain a light yellow oily liquid. The resulting oily silicone precursor was dissolved in DMF, and then ethyl orthosilicate and europium nitrate were added. The ratio of organic silicon precursor, ethyl orthosilicate and europium nitrate is 3:6:1. The pH value of the solution was adjusted to 1, and the hydrolysis polycondensation reaction was carried out at 20° C. for 5 hours until a solid gel was formed. The obtained solid gel was transferred to an oven for aging treatment, the temperature was controlled at 60° C., and the aging time was 10 days to finally obtain an organic-inorg...

Embodiment 2

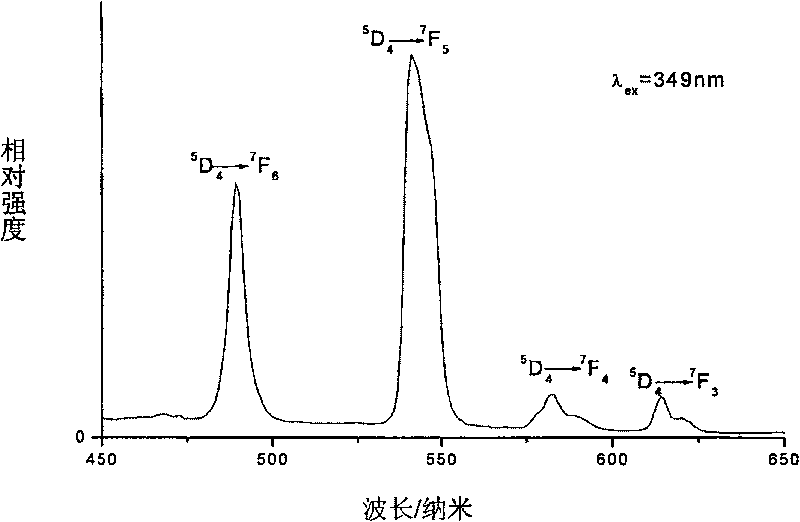

[0027] Dissolve 1 mmol of α-hydroxypyridine in 10 ml of DMF, add to a three-necked flask and heat to reflux. A solution of 10 ml of DMF dissolved with 1 mmol of triethoxysilylisocyanate was then added dropwise. After the dropwise addition, the entire solution was refluxed at 90° C. for 8 h under the protection of nitrogen, cooled, and the solvent was distilled off under reduced pressure to obtain a light yellow oily liquid. The resulting oily silicone precursor was dissolved in DMF, and then ethyl orthosilicate and terbium nitrate were added. The material ratio of the organosilicon precursor, tetraethyl orthosilicate and terbium nitrate is 3:6:1. The pH value of the solution was adjusted to 2, and the hydrolysis and polycondensation reaction was carried out at a temperature of 30° C. for 8 hours until a solid gel was formed. The obtained solid gel was transferred to an oven for aging treatment, the temperature was controlled at 70° C., and the aging time was 20 days to final...

Embodiment 3

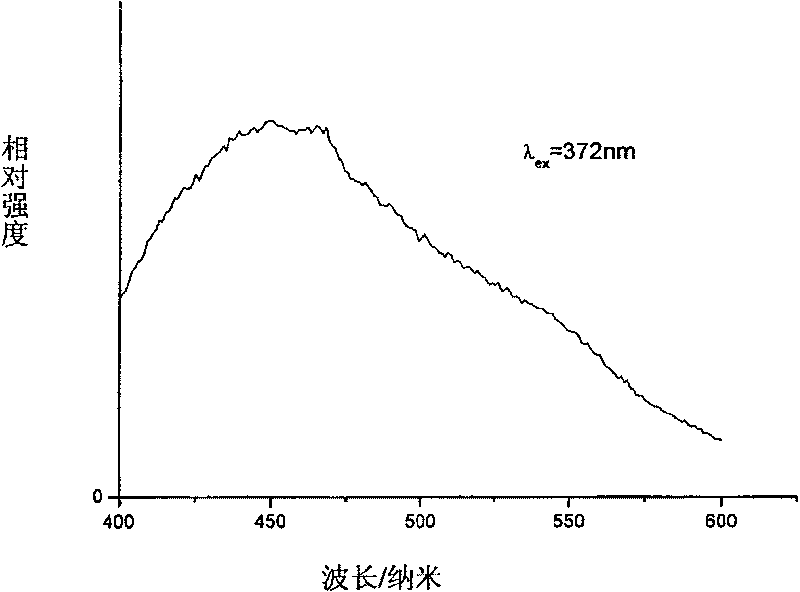

[0029] Dissolve 1 mmol of α-hydroxypyridine in 10 ml of DMF, add to a three-necked flask and heat to reflux. Then a solution of 1.2 mmol of triethoxysilylisocyanopropyl triethoxypropyl isocyanate dissolved in 10 ml of DMF was added dropwise. After the dropwise addition, the entire solution was refluxed at 100° C. for 10 h under the protection of nitrogen, cooled, and the solvent was distilled off under reduced pressure to obtain a light yellow oily liquid. The resulting oily silicone precursor was dissolved in DMF, and then ethyl orthosilicate and zinc acetate were added. The material ratio of the organosilicon precursor, tetraethyl orthosilicate and zinc acetate is 2:4:1. The pH value of the solution was adjusted to 3, and the hydrolysis and polycondensation reaction was carried out at a temperature of 40°C for 10 hours until a solid gel was formed. The obtained solid gel was transferred to an oven for aging treatment, the temperature was controlled at 80° C., and the aging...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com