Method for preparing rare-earth beta diketone-base functionalized non-linear optical composite material

A nonlinear optics and composite material technology is applied in the field of preparation of rare earth β-diketone functionalized nonlinear optical composite materials, which can solve the problems of poor light stability and thermal stability of pure rare earth organic complexes, and cannot be widely used. , to avoid the phenomenon of phase separation, good thermal stability and mechanical properties, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

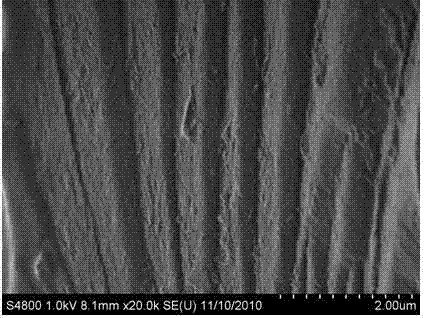

Image

Examples

Embodiment 1

[0030]Weigh 0.104g of hexafluoroacetylacetone and add it to a three-neck flask containing 20ml of tetrahydrofuran solution, stir to dissolve it, then add 0.012g of sodium hydride in 6ml of anhydrous tetrahydrofuran solution drop by drop, at 70°C, nitrogen Protect and heat to reflux for 2 h, and add dropwise a solution of 0.123 g of triethoxysilylisocyanopropyl isocyanate in 6 ml of tetrahydrofuran while stirring. Then keep the temperature of the whole solution at 65° C., reflux for 12 h under the protection of nitrogen, cool to room temperature, and distill off the organic solvent under reduced pressure. The resulting product was washed three times with 8 ml of cyclohexane to obtain a pale yellow oily liquid. Use 16ml of N,N dimethylformamide solvent to dissolve the obtained hexafluoroacetylacetonate bridge molecules, then take 0.226g of small organic molecules p-nitrostyryl pyridine and 0.231g of erbium nitrate and dissolve them in absolute ethanol to obtain The ethanol solu...

Embodiment 2

[0033] Add 0.111g of thienoyl trifluoroacetone into a three-necked flask filled with 20ml of tetrahydrofuran, stir to dissolve it, then add dropwise 6ml of tetrahydrofuran solution containing 0.012g of sodium hydride, at 70°C, Nitrogen protection was used to heat and reflux for 2 hours, and then a solution of 0.123 g of triethoxysilylisocyanate in 6 ml of tetrahydrofuran was added dropwise. Then, it was stirred and reacted at 65° C. under nitrogen protection for 12 h, cooled, and the solvent was distilled off under reduced pressure. The resulting product was washed three times with 12 ml of cyclohexane to obtain a pale yellow oily liquid. Use 16ml of N, N dimethylformamide solvent to dissolve the obtained thienoyl trifluoroacetone bridge molecule, then get the small organic molecule p-nitrostyryl pyridine 0.226g and 0.231g of erbium nitrate dissolved in anhydrous Obtain the ethanol solution of p-nitrostyrylpyridine and the ethanol solution of erbium nitrate in ethanol, under ...

Embodiment 3

[0035] Add 0.077 g of trifluoroacetylacetone into a three-necked flask containing 20 ml of tetrahydrofuran, stir to dissolve it, then add 6 ml of tetrahydrofuran solution containing 0.012 g of sodium hydride dropwise, and heat under nitrogen protection at 70°C Reflux for 2 h, and then add 0.123 g triethoxysilylisocyanopropyl isocyanate dissolved in 6 ml tetrahydrofuran solution dropwise. Then, it was stirred and reacted at 65° C. under nitrogen protection for 12 h, cooled, and the solvent was distilled off under reduced pressure. The resulting product was washed three times with 12 ml of cyclohexane to obtain a pale yellow oily liquid. Dissolve the obtained trifluoroacetylacetonate bridge molecule with 16ml of N,N dimethylformamide solvent, then take 0.226g of small organic molecules and 0.231g of erbium nitrate obtained in step (2) and dissolve them in absolute ethanol to obtain the The ethanol solution of nitrostyrylpyridine and the ethanol solution of erbium nitrate, under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com