Method for preparing light conversion composite nanopore material

A nanoporous material and light conversion technology, applied in luminescent materials, chemical instruments and methods, optics, etc., can solve the problems of poor photostability and thermal stability and poor luminescence performance of pure rare earth organic complexes, and achieve good thermal stability. Effect of stability and mechanical properties, good luminescent properties, good thermal stability and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

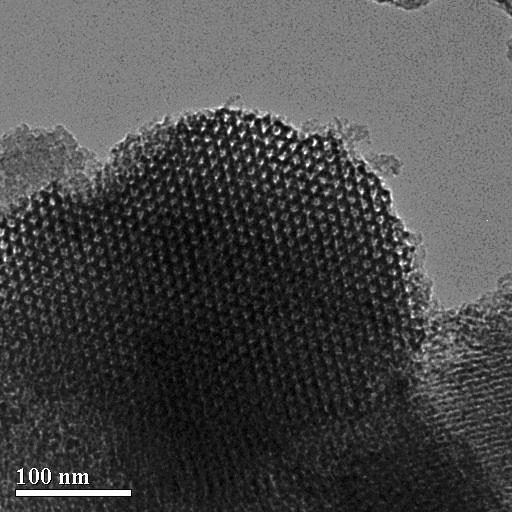

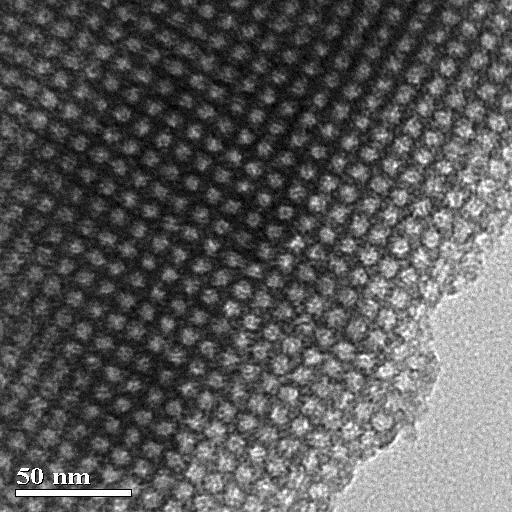

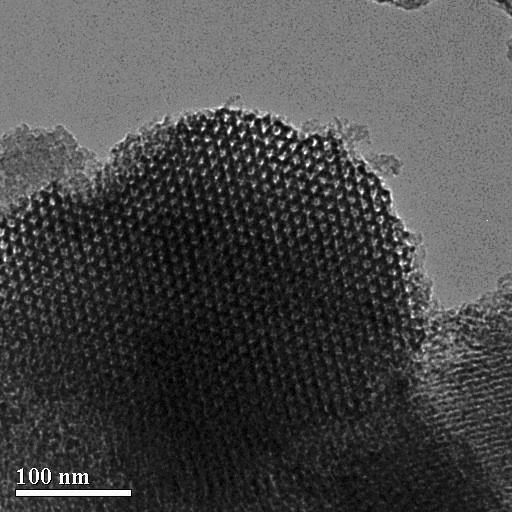

Image

Examples

Embodiment 1

[0027]Weigh 10 g of 2-methoxynaphthalene and 10.252 g of α-methylcinnamic acid, add 1,2-dichloroethane, dissolve, stir evenly, then add 13.119 g of phosphorus pentachloride to the solution, stir and reflux for 5 minutes , cooled in an ice bath, added 8.4 g of anhydrous aluminum chloride, stirred and refluxed for 10 minutes, then added 8.4 g of anhydrous aluminum chloride, stirred and refluxed overnight, the mixture was decomposed by pouring ice hydrochloric acid, the organic layer was washed with water and washed with anhydrous sodium sulfate Dry and remove the solvent to obtain a red viscous oil, mix it with 25.2 g of anhydrous aluminum chloride, put it in an oil bath heated to 180 ° C, react for 1 h, pour the mixture into glacial hydrochloric acid, and extract it with dichloromethane , the organic layer was washed with water and dried with anhydrous sodium sulfate, and the solvent was removed to obtain a black oil, which was sublimated with ethanol and recrystallized to obtai...

Embodiment 2

[0029] Weigh 10 g of 2-methoxynaphthalene and 10.252 g of α-methylcinnamic acid, add 1,2-dichloroethane, dissolve, stir evenly, then add 13.119 g of phosphorus pentachloride to the solution, stir and reflux for 5 minutes , cooled in an ice bath, added 8.4 g of anhydrous aluminum chloride, stirred and refluxed for 10 minutes, then added 8.4 g of anhydrous aluminum chloride, stirred and refluxed overnight, the mixture was decomposed by pouring ice hydrochloric acid, the organic layer was washed with water and washed with anhydrous sodium sulfate Dry and remove the solvent to obtain a red viscous oil, mix it with 25.2 g of anhydrous aluminum chloride, put it in an oil bath heated to 180 ° C, react for 1 h, pour the mixture into glacial hydrochloric acid, and extract it with dichloromethane , the organic layer was washed with water and dried with anhydrous sodium sulfate, and the solvent was removed to obtain a black oil, which was sublimated with ethanol and recrystallized to obta...

Embodiment 3

[0031] Weigh 10 g of 2-methoxynaphthalene and 10.252 g of α-methylcinnamic acid, add 1,2-dichloroethane, dissolve, stir evenly, then add 13.119 g of phosphorus pentachloride to the solution, stir and reflux for 5 minutes , cooled in an ice bath, added 8.4 g of anhydrous aluminum chloride, stirred and refluxed for 10 minutes, then added 8.4 g of anhydrous aluminum chloride, stirred and refluxed overnight, the mixture was decomposed by pouring ice hydrochloric acid, the organic layer was washed with water and washed with anhydrous sodium sulfate Dry and remove the solvent to obtain a red viscous oil, mix it with 25.2 g of anhydrous aluminum chloride, put it in an oil bath heated to 180 ° C, react for 1 h, pour the mixture into glacial hydrochloric acid, and extract it with dichloromethane , the organic layer was washed with water and dried with anhydrous sodium sulfate, and the solvent was removed to obtain a black oil, which was sublimated with ethanol and recrystallized to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com