Method for preparing polymethylacrylic acid functionalized rare-earth polymer composite luminescent material

A polymethacrylic acid, functional polymer technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of poor light and thermal stability, affect optical properties, limit applications, etc., and achieve easy processing and operability. Strong and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

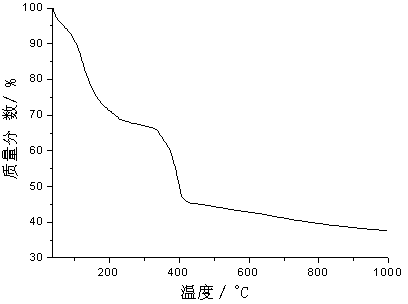

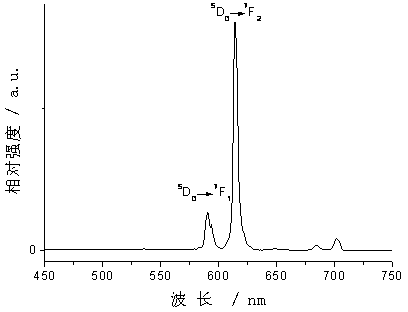

[0022] Dissolve 0.258g of methacrylic acid and 0.148g of vinyltrimethoxysilane in 10mL of absolute ethanol, add them into a three-necked flask, and heat to 70-80°C. Then, an absolute ethanol solution dissolved with 0.01 g of the initiator benzoyl peroxide was added dropwise into the three-necked flask. The whole solution is controlled at 70-80°C, stirred and reacted for 10 hours under the protection of nitrogen, cooled, and evaporated to dryness of organic solvent and polymer monomer not participating in the reaction, and a white solid is obtained. Subsequently, the obtained white solid was dissolved in 10 mL of N,N-dimethylformamide (DMF) and placed in another flask, and a solution of 0.338 g of europium nitrate in absolute ethanol was added dropwise, and then 0.36 g of , 10-phenanthroline, stirring for 5 hours at a temperature of 20-30°C. Then, tetraethyl orthosilicate and deionized water are added dropwise to adjust the pH value to 6-7. The molar ratio of methacrylic acid...

Embodiment 2

[0024] Dissolve 0.258g of methacrylic acid and 0.148g of vinyltrimethoxysilane in 10mL of absolute ethanol, add them into a three-necked flask, and heat to 70-80°C. Then, an absolute ethanol solution dissolved with 0.01 g of the initiator benzoyl peroxide was added dropwise into the three-necked flask. The whole solution is controlled at 70-80°C, stirred and reacted for 10 hours under the protection of nitrogen, cooled, and evaporated to dryness of organic solvent and polymer monomer not participating in the reaction, and a white solid is obtained. Subsequently, the obtained white solid was dissolved in 10 mL of N,N-dimethylformamide (DMF) and placed in another flask, a solution of 0.345 g of terbium nitrate in absolute ethanol was added dropwise, and then 0.36 g of 1 , 10-phenanthroline, stirring for 5 hours at a temperature of 20-30°C. Then, tetraethyl orthosilicate and deionized water are added dropwise to adjust the pH value to 6-7. The molar ratio of methacrylic acid, t...

Embodiment 3

[0026] Dissolve 0.315g of 4-vinylpyridine and 0.148g of vinyltrimethoxysilane in 10mL of absolute ethanol, add them into a three-necked flask, and heat to 70-80°C. Then, an absolute ethanol solution dissolved with 0.01 g of the initiator benzoyl peroxide was added dropwise into the three-necked flask. The whole solution is controlled at 70-80° C., stirred and reacted for 10 h under the protection of nitrogen, cooled, evaporated to dryness of the organic solvent and the polymer monomer not participating in the reaction, and a solid is obtained. Subsequently, the obtained solid was dissolved in 10 mL of N,N-dimethylformamide (DMF) and placed in another flask, a solution of 0.338 g of europium nitrate in absolute ethanol was added dropwise, and then 0.36 g of 1, 10-Phenanthroline, stirred for 5 hours at a temperature of 20-30°C. Then add tetraethyl orthosilicate and deionized water dropwise to adjust the pH value to 6-7. The ratio is 1:1:2:6:12. The whole solution is at a temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com