Catalyst for preparing methyl alcohol by carbon dioxide catalytic hydrogenation and preparing method thereof

A technology for catalytic hydrogenation and carbon dioxide, applied in the direction of catalyst activation/preparation, preparation of organic compounds, physical/chemical process catalysts, etc., can solve problems such as waste of carbon resources and environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

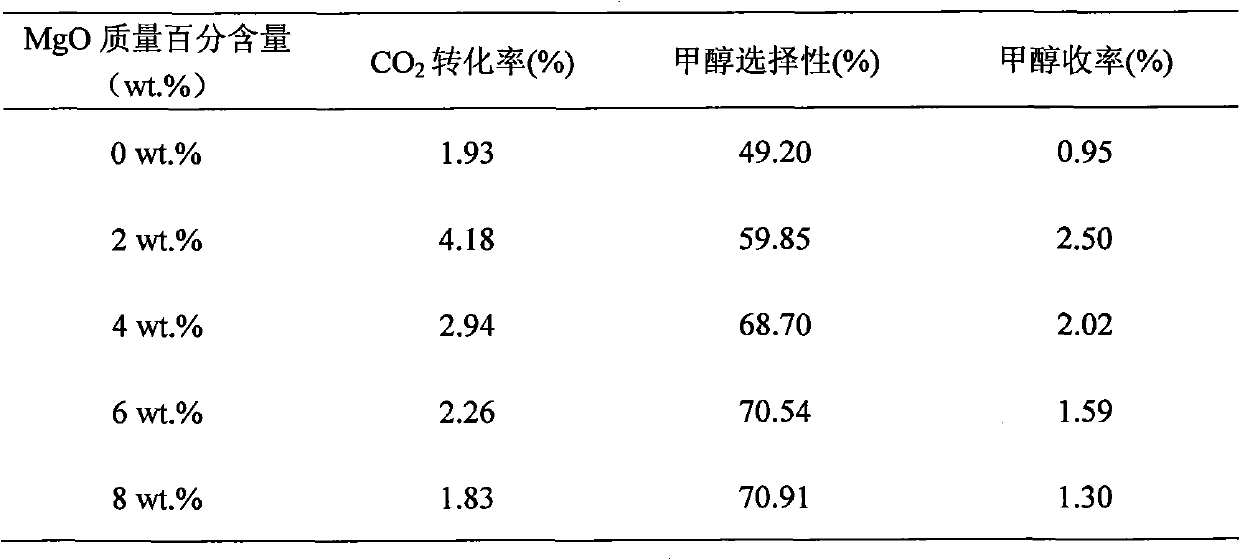

Examples

Embodiment 1

[0017] Weigh 4.55gCu(NO 3 ) 2 ·3H 2 O, 10.95gZn(NO 3 ) 2 ·6H 2 O, 3.68gAl(NO 3 ) 3 9H 2 O, 0.64gMg(NO 3 ) 2 ·6H 2 O was dissolved in 100ml ethanol, the solution was recorded as A solution, and 8.91gH was weighed 2 C 2 o 4 ·H 2 O is dissolved in 50ml of ethanol, and the solution is recorded as solution B. At 70°C and stirring, drop liquid B into liquid A for a coprecipitation reaction to obtain a precipitation solution (1). Keep stirring at 70°C until the ethanol is completely evaporated , then dry the obtained catalyst precursor at 110°C for 12 hours, heat up to 350°C at a rate of 3.0°C / min and roast for 4 hours, then cool down to room temperature, grind, tablet, crush, and sieve to obtain particles with a certain particle size , that is, a catalyst for catalytic hydrogenation of carbon dioxide to methanol is obtained.

Embodiment 2

[0019] Weigh 4.55gCu(NO 3 ) 2 ·3H 2 O, 10.95gZn(NO 3 ) 2 ·6H 2 O, 3.68gAl(NO 3 ) 3 9H 2 O, 0.64gMg(NO 3 ) 2 ·6H 2 O was dissolved in 100ml of water, the solution was recorded as liquid A, and 8.91gH was weighed 2 C 2 o 4 ·H 2 O was dissolved in 50ml of water, and the solution was recorded as solution B. Under stirring conditions at 70°C, drop liquid B into liquid A for co-precipitation reaction to obtain a precipitate (1), react at 70°C and stirring conditions for 4 hours, and age 1 hour, then filter and wash the obtained catalyst precursor precipitation, control the pH value of the filtrate between 7 and 8, dry the filter cake at 110°C for 12 hours, and heat up to 350°C at a rate of 3.0°C / min for roasting After 4 hours, cool down to room temperature, grind, tablet, crush, and sieve to obtain particles with a certain particle size, that is, a catalyst for catalytic hydrogenation of carbon dioxide to methanol is obtained.

Embodiment 3

[0021] Weigh 4.55gCu(NO 3 ) 2 ·3H 2 O, 10.95gZn(NO 3 ) 2 ·6H 2 O, 3.68gAl(NO 3 ) 3 9H 2 O, 0.64gMg(NO 3 ) 2 ·6H 2 O was dissolved in 100ml of water, the solution was recorded as solution A, and 8.22gNa was weighed 2 C0 3 Dissolve in 50ml of water, and record the solution as B solution. Drop B solution into A solution for co-precipitation reaction at 70°C and stirring condition to obtain precipitation solution (1), react at 70°C and stirring condition for 4 hours, and age for 1 hour, then the obtained catalyst precursor precipitation was filtered and washed, the pH value of the filtrate was controlled between 7 and 8, the filter cake was dried at 110°C for 12 hours, and the temperature was raised to 350°C at a rate of 3.0°C / min for 4 hours. Hours, down to room temperature, grinding, tableting, crushing, and sieving to obtain particles with a certain particle size, that is, a catalyst for catalytic hydrogenation of carbon dioxide to methanol is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com