Power plant flue-gas SCR denitration catalyst capable of preventing sulfur trioxide poisoning and preparation method thereof

A denitrification catalyst and catalyst technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of reduced catalyst activity and disadvantages, and achieve low cost, Easy to operate, good anti-SO3 poisoning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

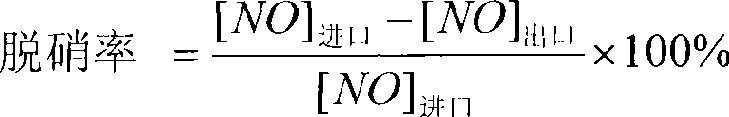

Method used

Image

Examples

Embodiment 1

[0017] Weigh 500g of metatitanic acid and 16.89g of ammonium paratungstate, dissolve the ammonium paratungstate in oxalic acid, mix the metatitanic acid and the oxalic acid solution of ammonium paratungstate, stir well, dry and calcinate in air for 6 hours, and grind to obtain tungsten-doped titanium dioxide Take by weighing 1.62g ammonium metavanadate and dissolve in oxalic acid solution, mix the oxalic acid solution of 100g tungsten-doped titanium dioxide and ammonium metavanadate evenly, then add additives such as clay, glass fiber and polyethylene oxide, wherein the tungsten The loaded amount is 10%, the loaded amount of vanadium is 1%, and the loaded amount of germanium or zinc is 3%, mechanically stirred for 1-2 hours to make it evenly mixed, put it in a drying oven, and heat it at a temperature of 70-110°C Drying in the air for 2-4 hours, then calcining in the air at 350-650°C for 3-6 hours, grinding and sieving after cooling, and taking the 40-60 mesh part as the cataly...

Embodiment 2

[0028] Weigh 750g of metatitanic acid and 25.34g of ammonium paratungstate, dissolve the ammonium paratungstate in oxalic acid, mix the metatitanic acid and the oxalic acid solution of ammonium paratungstate, stir well, dry and calcinate in air for 7 hours, and grind to obtain tungsten-doped titanium dioxide ; Take by weighing 2.587g ammonium metavanadate and be dissolved in oxalic acid solution, the oxalic acid solution of 100g doping tungsten titanium dioxide and ammonium metavanadate is evenly mixed, then add binding agent, additive and strengthening agent, wherein the loading capacity of tungsten is 8%, the vanadium load is 1.6%, the germanium or zinc load is 2%, stir mechanically for 1-2 hours to make it evenly mixed, put it in a drying oven, and dry it at a temperature of 70-110°C. The time is 2-4 hours, and then it is calcined at 350-650°C in the air for 3-6 hours. After cooling, it is ground and sieved, and the part with 40-60 meshes is used as the catalyst.

[0029] T...

Embodiment 3

[0031] Weigh 550g of metatitanic acid and 18.58g of ammonium paratungstate, dissolve ammonium paratungstate in oxalic acid, mix the oxalic acid solution of metatitanic acid and ammonium paratungstate, stir well, dry and calcinate in air for 6 hours, and grind to obtain tungsten-doped titanium dioxide ; Take by weighing 1.29g ammonium metavanadate and be dissolved in oxalic acid solution, mix the oxalic acid solution of 100g tungsten-titanium dioxide and ammonium metavanadate evenly, then add binding agent, additive and reinforcing agent, wherein the loading capacity of tungsten is 12%, the vanadium load is 0.8%, the germanium or zinc load is 4%, and mechanically stirred for 1-2 hours to make it evenly mixed, put it in a drying oven, and dry it at a temperature of 70-110°C. The time is 2-4 hours, and then it is calcined at 350-650°C in the air for 3-6 hours. After cooling, it is ground and sieved, and the part with 40-60 meshes is used as the catalyst.

[0032] The test method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com