Silver nanometer column array erected on orifice of porous alumina template and preparation method and application thereof

A technology of porous alumina and alumina template, applied in ion implantation plating, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of high SERS performance, inability to obtain, unfavorable target molecule adsorption, etc., to improve SERS Activity, improve the effect of electromagnetic field enhancement, and is conducive to effective adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

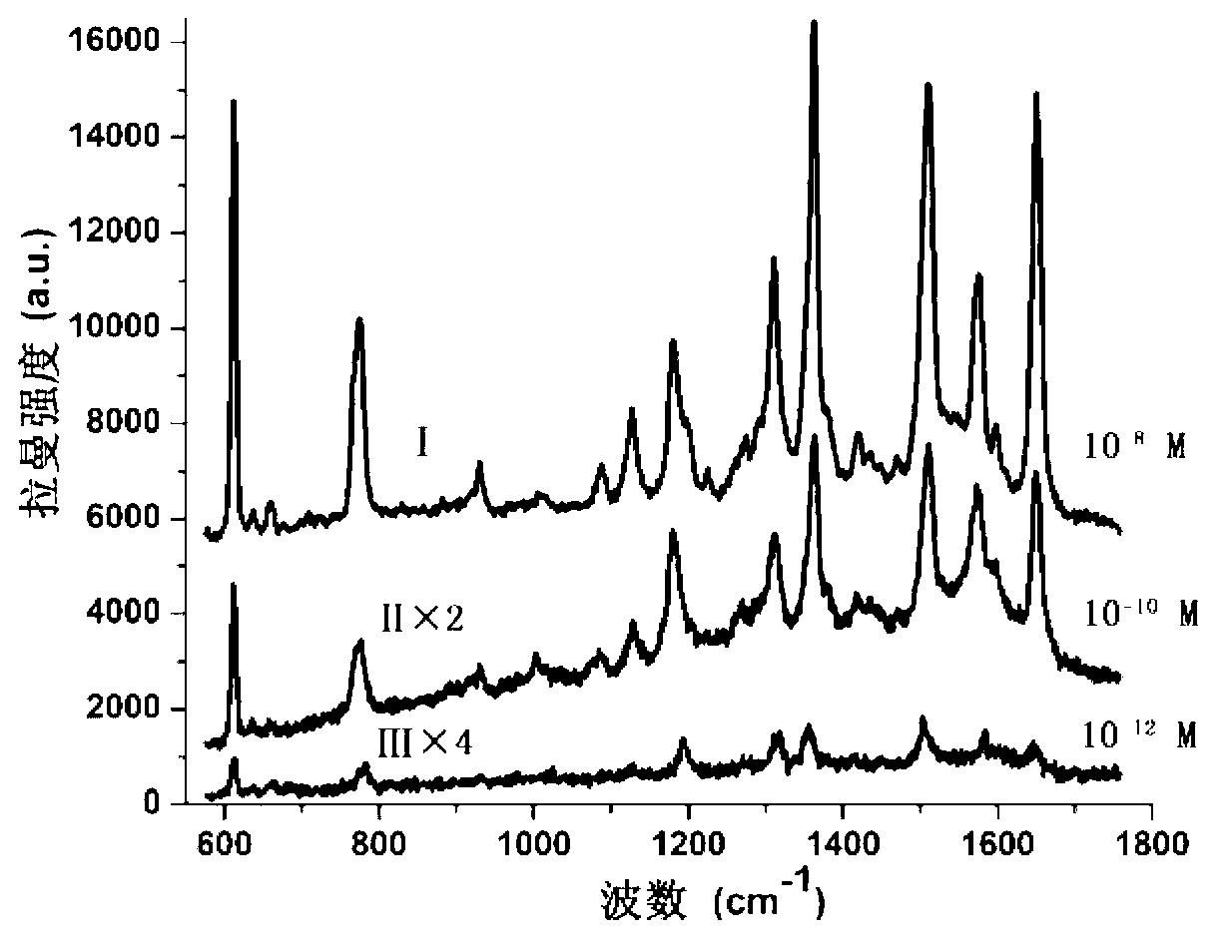

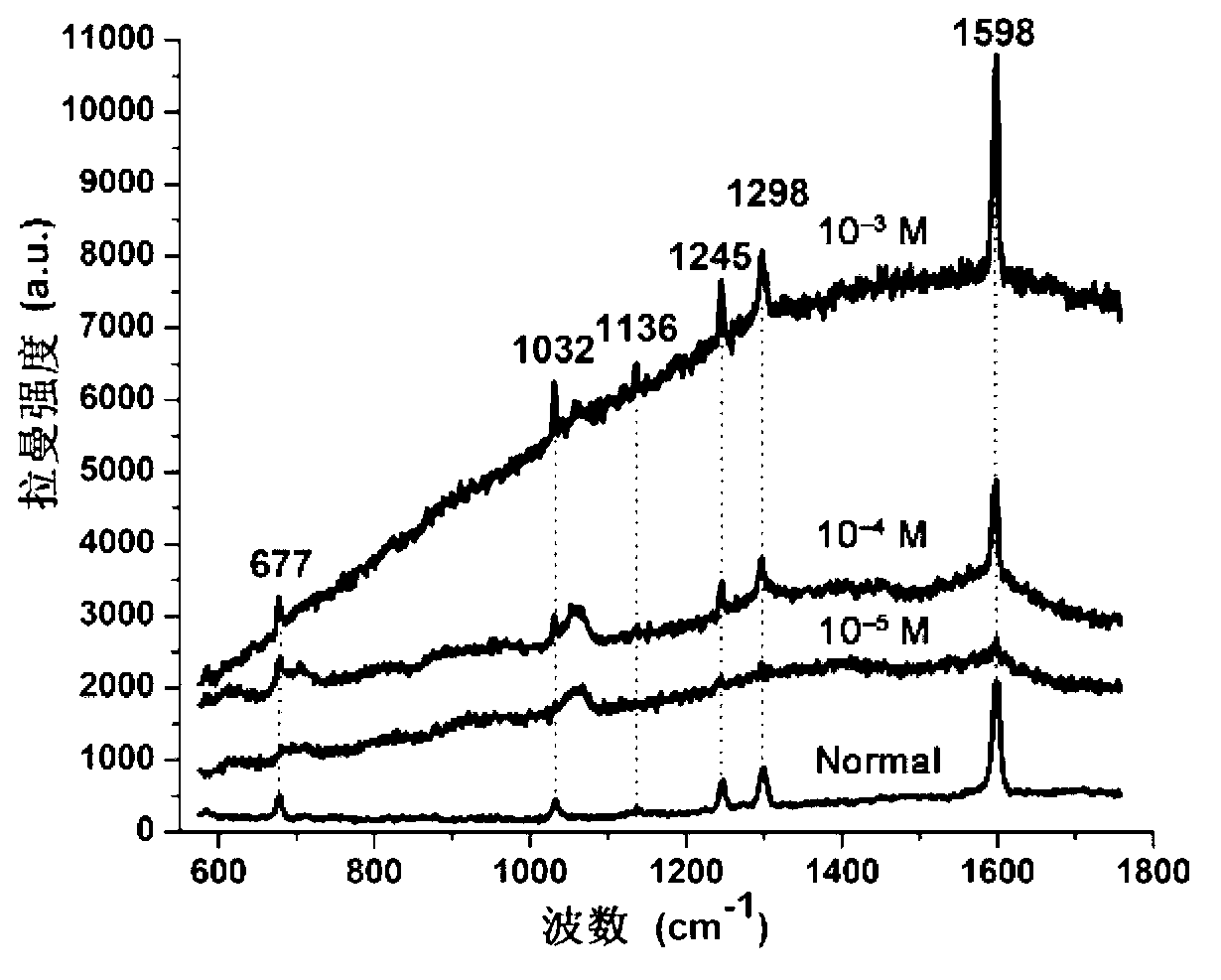

Examples

Embodiment 1

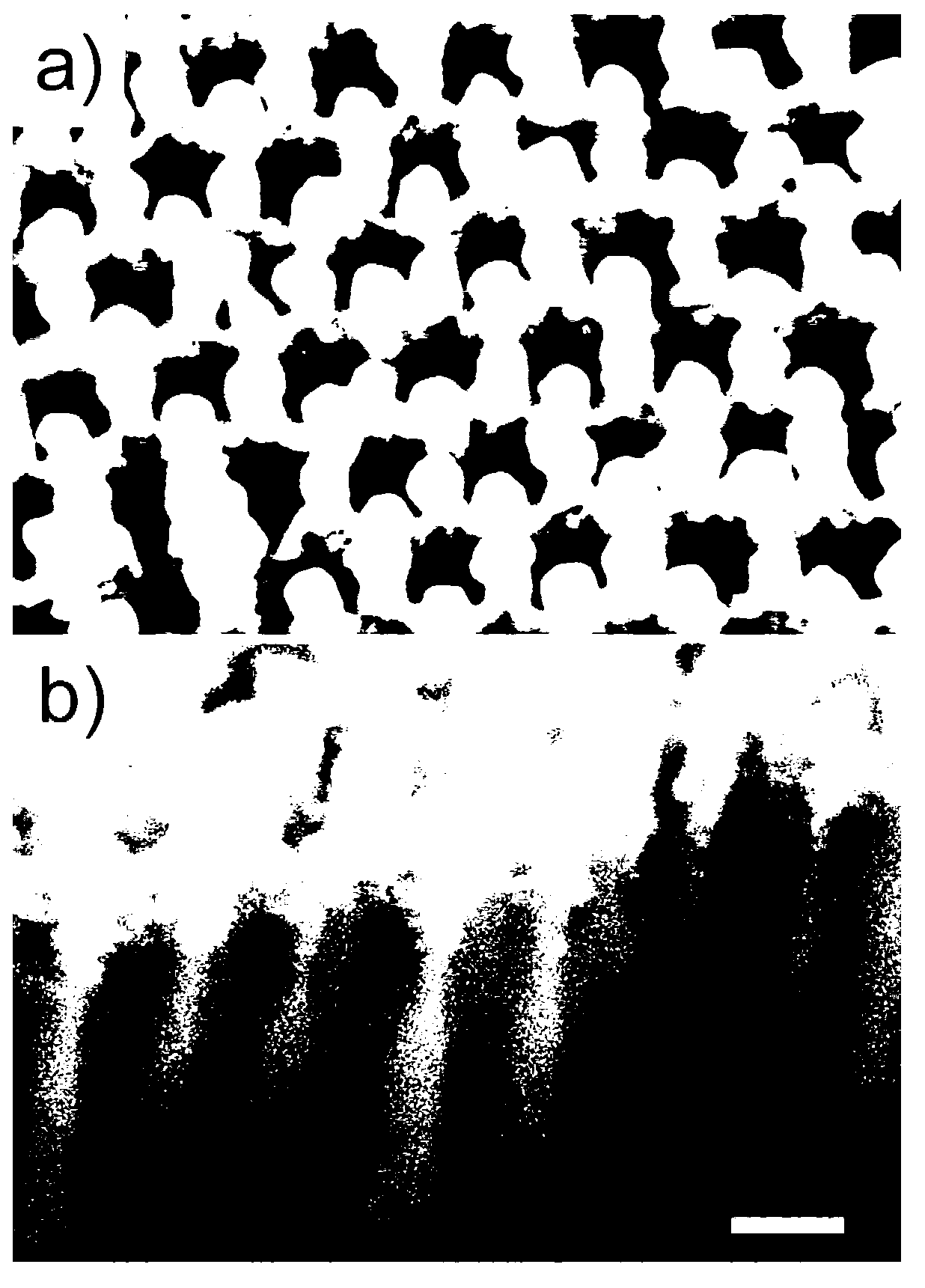

[0029] The concrete steps of preparation are:

[0030] Step 1, first place the aluminum sheet in an oxalic acid solution with a temperature of 6°C and a concentration of 0.2mol / L, and anodize it at a DC voltage of 30V for 4h. Then soak it in a mixed solution of phosphochromic acid at 55° C. for 6 hours to obtain an intermediate product.

[0031] In step 2, the intermediate product is placed in an oxalic acid solution with a temperature of 6°C and a concentration of 0.2 mol / L, and anodized at a DC voltage of 30V for 60s. Then soak it in a phosphoric acid solution with a temperature of 30°C and a concentration of 3wt% for 10 minutes, repeat the above process 10 times, and obtain an alumina template with conical holes.

[0032] Step 3, place the aluminum oxide template with a tapered hole in the ion sputtering device so that the distance between it and the silver target in the ion sputtering device is 8 cm, the current during sputtering is 10 mA, and the time is 30 min. made ap...

Embodiment 2

[0034] The concrete steps of preparation are:

[0035] Step 1, first place the aluminum sheet in an oxalic acid solution with a temperature of 10°C and a concentration of 0.25mol / L, and anodize it at a DC voltage of 35V for 3.5h. Then soak it in a mixed solution of phosphochromic acid at 58° C. for 5 hours to obtain an intermediate product.

[0036] In step 2, the intermediate product is placed in an oxalic acid solution at a temperature of 10° C. and a concentration of 0.25 mol / L, and anodized at a DC voltage of 35 V for 50 seconds. Then soak it in a phosphoric acid solution with a temperature of 35°C and a concentration of 4wt% for 8 minutes, repeat the above process 13 times, and obtain an alumina template with conical holes.

[0037] Step 3, place the aluminum oxide template with a tapered hole in the ion sputtering device so that the distance between it and the silver target in the ion sputtering device is 9 cm, the current during sputtering is 18 mA, and the time is 26 ...

Embodiment 3

[0039] The concrete steps of preparation are:

[0040] Step 1, first place the aluminum sheet in an oxalic acid solution with a temperature of 15°C and a concentration of 0.3mol / L, and anodize it at a DC voltage of 40V for 3h. Then soak it in a mixed solution of phosphochromic acid at 60° C. for 4.5 hours to obtain an intermediate product.

[0041] In step 2, the intermediate product is placed in an oxalic acid solution with a temperature of 15° C. and a concentration of 0.3 mol / L, and anodized at a DC voltage of 40 V for 40 seconds. Then soak it in a phosphoric acid solution with a temperature of 40°C and a concentration of 6wt% for 6 minutes, repeat the above process 15 times, and obtain an alumina template with conical holes.

[0042] Step 3, place the aluminum oxide template with a tapered hole in the ion sputtering device so that the distance between it and the silver target in the ion sputtering device is 10 cm, the current during sputtering is 25 mA, and the time is 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com