Method for heat treatment of silicon substrate, substrate treated by the method, and epitaxial wafer utilizing the substrate

a technology of epitaxial wafers and silicon substrates, applied in the direction of after-treatment details, crystal growth process, polycrystalline material growth, etc., can solve the problems of poor accuracy, complex production operation, and degradation of device yield

Inactive Publication Date: 2000-11-07

SHIN-ETSU HANDOTAI CO LTD

View PDF3 Cites 35 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When the oxide precipitates are in the device active regions, they may be a cause of degradation of device yield.

Therefore, the production operation becomes complicated, and in addition the accuracy is bad.

Further, even though a crystal have a constant oxygen concentration along the crystal growth direction, the oxygen precipitation characteristic along the growth axis direction is not necessarily uniform due to influence of the thermal history during the crystal production.

To obtain uniform oxygen precipitation characteristic, heat treatment of long period of time is required, and hence the productivity becomes low.

On the other hand, as for an epitaxial wafer manufactured by using a silicon substrate produced by the CZ method, when epitaxial growth is performed using a silicon substrate having a usual resistivity, potential oxygen precipitation nuclei formed during the substrate production (crystal production) are eliminated by t

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

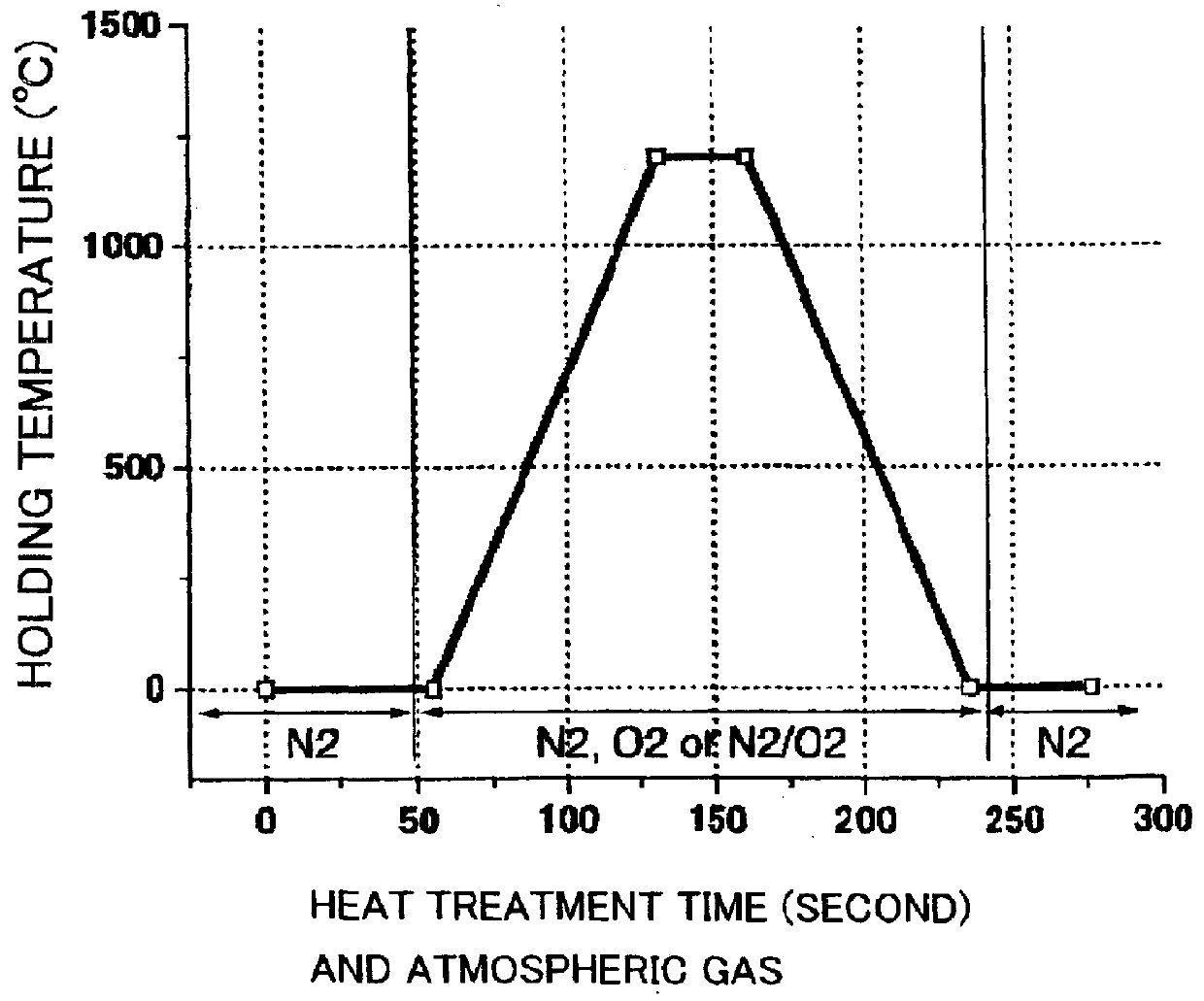

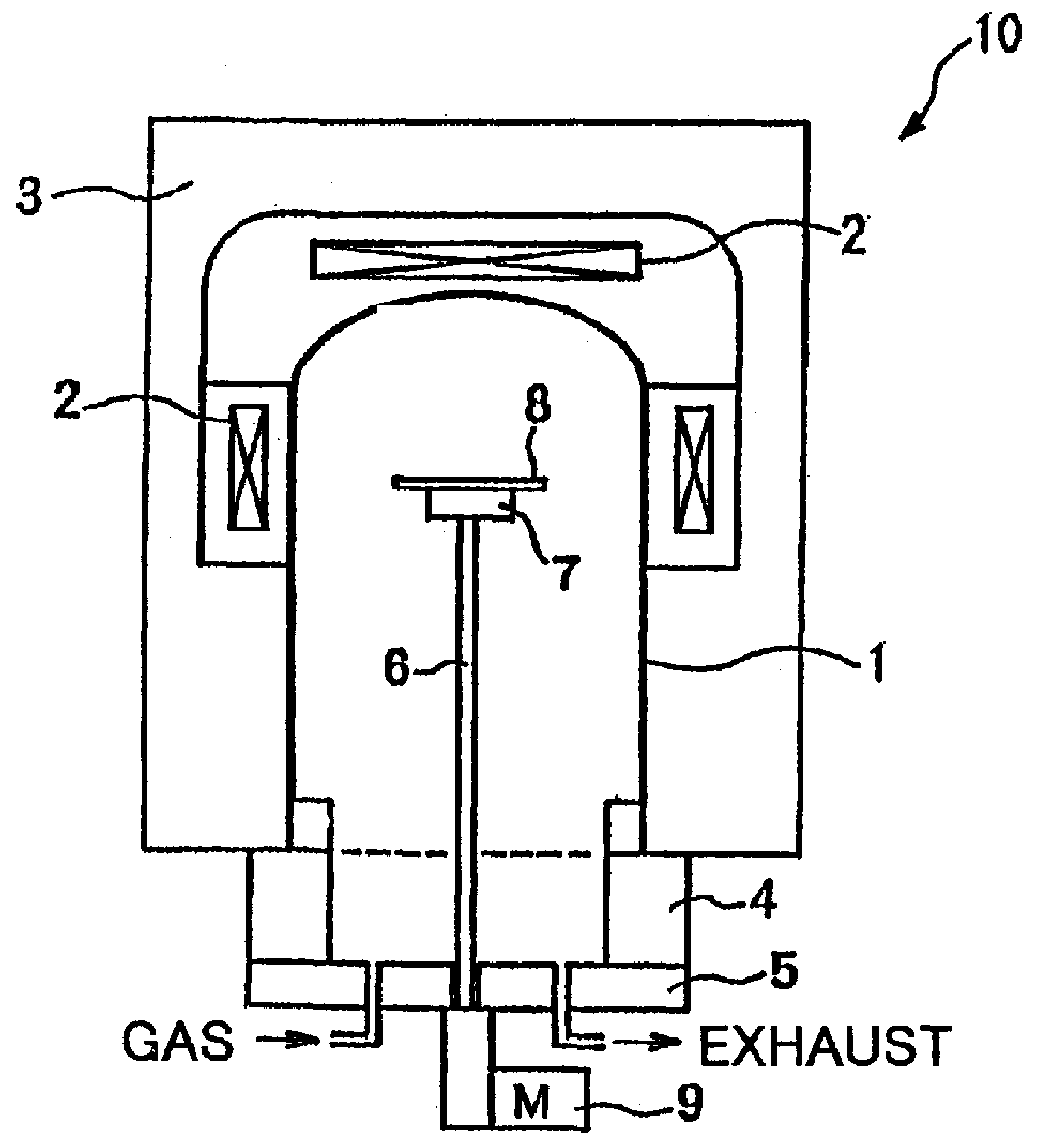

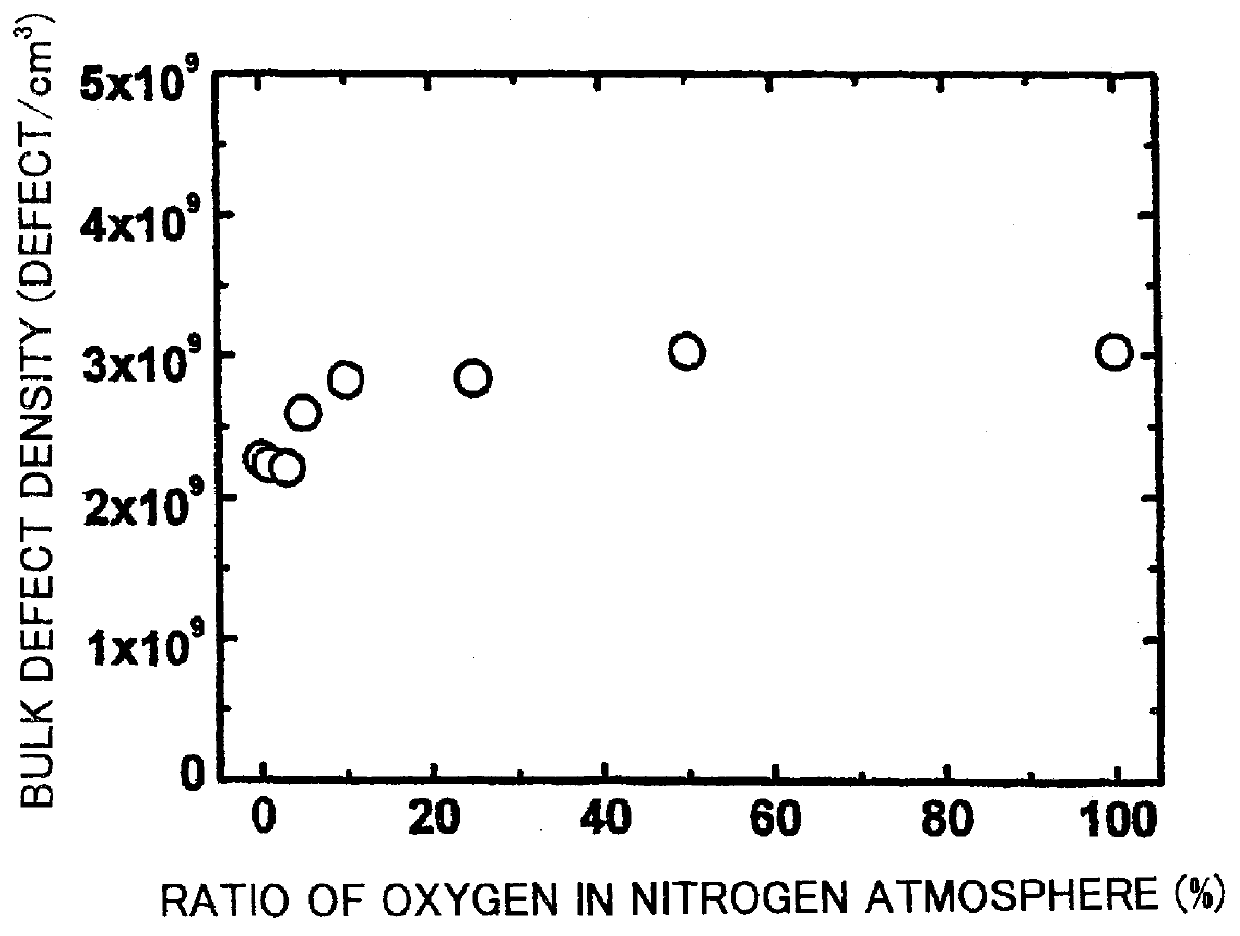

There is disclosed a method for heat treatment of a silicon substrate produced by the CZ method by utilizing a rapid thermal annealer, wherein the heat treatment is performed under an atmosphere composed of 100% nitrogen, or 100% oxygen, or a mixed atmosphere of oxygen and nitrogen by heating the silicon substrate to a maximum holding temperature within a range of from 1125 DEG C. to the melting point of silicon, and holding the substrate at that maximum holding temperature for a holding time of 5 seconds or more, and then the substrate is rapidly cooled at a cooling rate of 8 DEG C./second or more from the maximum holding temperature. In the method, the amount of oxygen precipitation nuclei in the substrate can be controlled by changing the maximum holding temperature and the holding time. The present invention provide a method for heat treatment of a silicon substrate produced by the CZ method by utilizing an RTA apparatus, which can provide a silicon substrate having a desired oxygen precipitation characteristic without controlling oxygen concentration in the silicon substrate, and an epitaxial wafer utilizing a substrate heat-treated by the method.

Description

1. Field of the InventionThe present invention relates to a method for heat treatment of a silicon substrate produced by the Czochralski method (CZ method), and an epitaxial wafer produced by using a substrate heat-treated by the method. In particular, it relates to a method for heat treatment for obtaining a semiconductor substrate imparted with internal gettering ability through a high temperature heat treatment in a short period of time.2. Description of Related ArtSilicon crystals produced by the CZ method contain not a little oxygen, because a crucible made of quartz is used for the production. It has been known that this oxygen forms precipitates during the production of the crystals and the heat treatment in the device fabrication process after slicing and substrate processing of the crystals.When the oxide precipitates are in the device active regions, they may be a cause of degradation of device yield. On the other hand, the oxide precipitates formed in the inside of substr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C30B33/00H01L21/322H01L21/324

CPCC30B33/00C30B29/06H01L21/324

Inventor AIHARA, KENTAKENO, HIROSHI

Owner SHIN-ETSU HANDOTAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com