Magnetic material with bidirectional shape memory effect and single-crystal producing method thereof

A technology of memory effect and magnetic materials, applied in the field of shape memory materials, can solve the problems of high brittleness of parent phase and low phase transition temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation composition is: Mn 2 NiGa is a magnetic alloy with magnetically induced high strain and shape memory effect. It is heated by radio frequency with a growth parameter of 245 kHz, and argon with a positive pressure of 0.01 to 1 MPa is used as a protective gas. In a magnetic levitation cold crucible, the heating power is 20 Kilowatt, its preparation method is carried out according to the following specific steps:

[0023] (1) Weighing Mn39.19 grams, Ni20.94 grams and Ga24.87 grams with a purity of 99.9% respectively;

[0024] (2) Put the weighed material into the crucible, heat it to 1230°C to melt, keep it for 10-30 minutes, and the synthetic composition is Mn 2 The raw material of NiGa weighs 85 grams in total;

[0025] (3) Use Mn of 2×2×7mm size 2 NiGa[001] oriented single crystal is used as seed crystal to grow single crystal;

[0026] During the growth process, the rotation rate of the seed rod is 30 rpm, and the pulling growth rate is 30mm / hour;

...

Embodiment 2

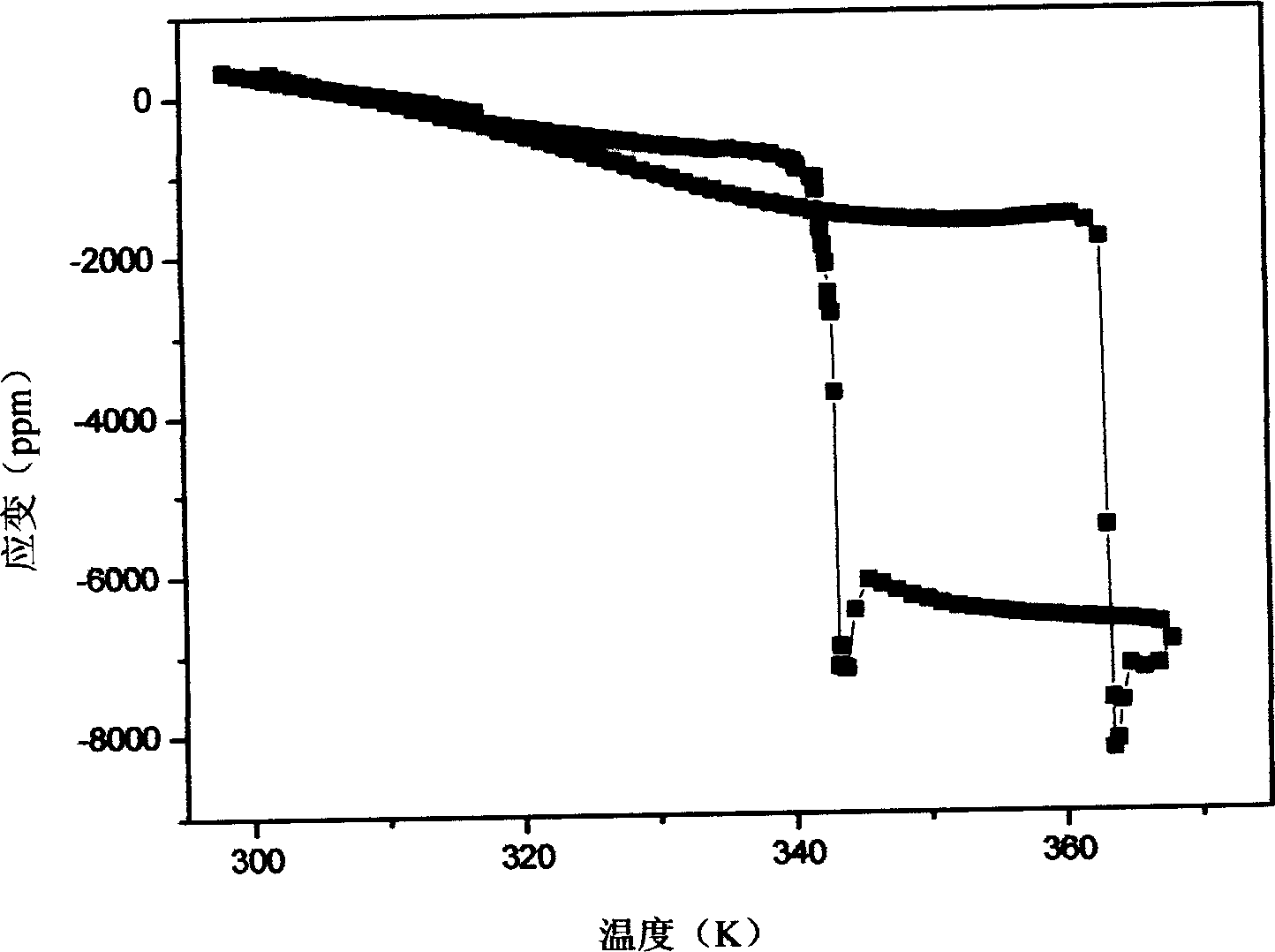

[0031] The preparation composition is: Mn 45 Ni 30 Ga 25 A magnetic alloy with magnetically induced high strain and shape memory effect; the difference is that in a quartz crucible, it is grown by resistance heating, except that the rotation rate of the seed rod is 20 revolutions / minute, and the pulling growth rate is 10mm / hour , all the other are with embodiment 1, and its phase transition temperature and Curie temperature are shown in Table 1. Measure the strain of its shape memory effect, and obtain the characteristic curve whose shape is shown in the accompanying drawing, and its values are shown in Table 3.

Embodiment 3

[0033] The preparation composition is: Mn 40 Ni 35 Ga 25 A magnetic alloy with magnetically induced high strain and shape memory effect; except that the rotation rate of the seed rod is 10 rpm and the pulling growth rate is 50 mm / hour, all the other are the same as in Example 1, its phase transition temperature and Curie temperature See Table 1. Measure the strain of its shape memory effect, and obtain the characteristic curve whose shape is shown in the accompanying drawing, and its values are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com