Method and device for improving uniformity of axial resistivity of czochralski monocrystalline silicon

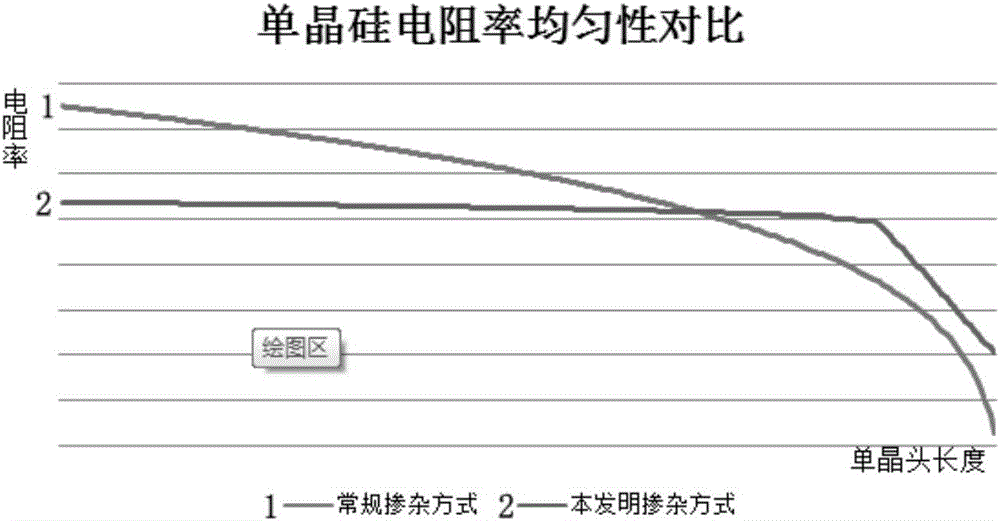

A technology of resistivity and uniformity, which is applied in the field of improving the axial resistivity uniformity of Czochralski single crystal silicon, can solve the problems of resistivity reduction, doping element concentration difference, doping element entry, etc., to achieve the improvement of uniformity, Ease of operation and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

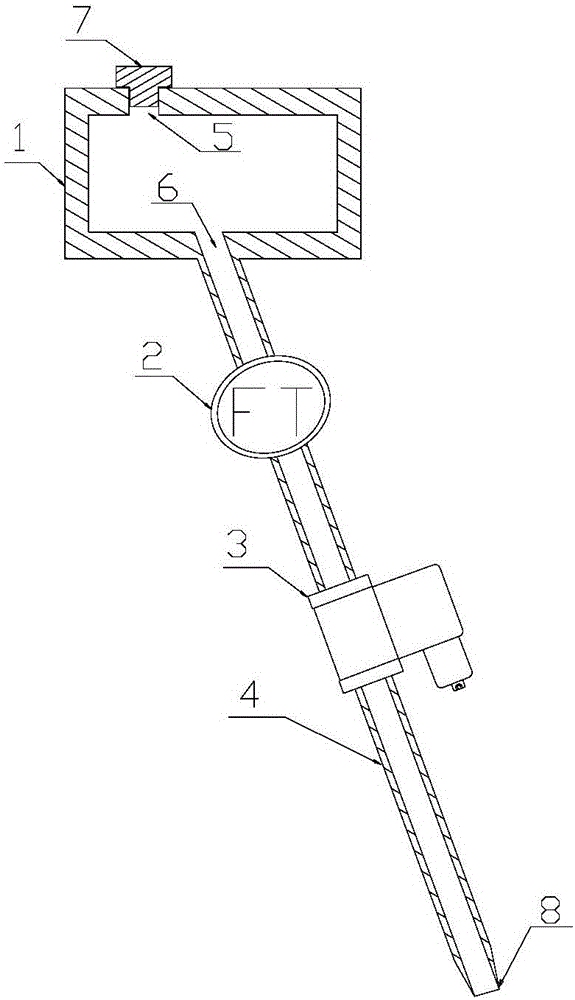

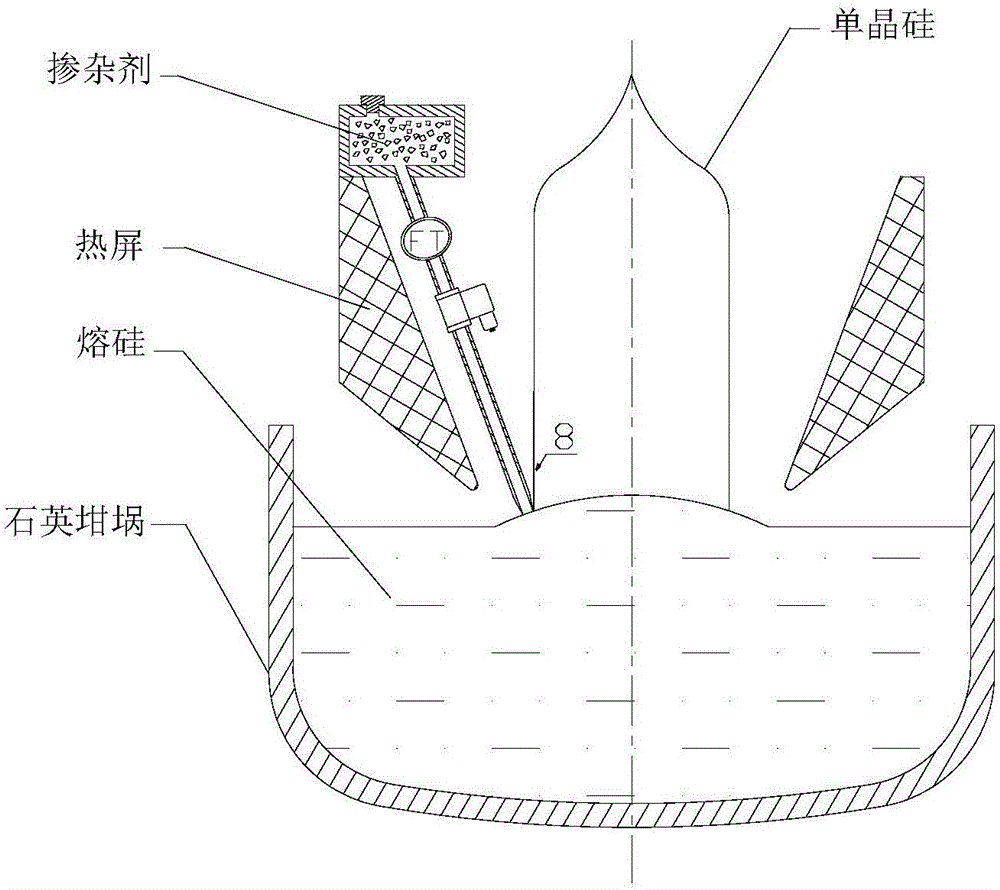

[0026] Embodiment 1: A device for improving the axial resistivity uniformity of Czochralski single crystal silicon, which includes: a dopant container 1, a mass flow meter 2, a solenoid valve 3 and a delivery pipe 4, and the top of the dopant container 1 A dopant inlet 5 is provided, and the bottom of the dopant container 1 is provided with a dopant outlet 6, and the dopant inlet 5 is provided with a sealing cover 7 matched with the dopant inlet 5; the dopant A conveying pipe 4 is provided below the container 1, the upper end inlet of the conveying pipe 4 is connected with the dopant outlet 6, and the lower end of the conveying pipe 4 is connected with a tip outlet 8; the conveying pipe 4 is provided with a mass flow meter 2 and a solenoid valve 3 , the mass flow meter 2 is electrically connected with the solenoid valve 3 .

[0027] The conveying pipe 4 is arranged inclined from top to bottom. The inner diameter of the nozzle outlet 8 is 1-5mm, the wall thickness of the nozzle...

Embodiment 2

[0028] Embodiment 2: A method for improving the uniformity of axial resistivity of Czochralski monocrystalline silicon, which includes the following steps: (1) preparation before the start of monocrystalline silicon pulling; (2) melting polysilicon raw materials; (3) seeding Steps; (4) Steps of putting shoulders; (5) Steps of turning shoulders; (6) Steps of equal diameter; (7) Finishing steps;

[0029] (1) The preparation before the start of monocrystalline silicon pulling is specifically: before the start of single crystal silicon pulling, prepare a device for improving the uniformity of the axial resistivity of Czochralski single crystal silicon, which includes: a dopant container 1, a mass flow meter 2. Electromagnetic valve 3 and conveying pipe 4, the top of dopant container 1 is provided with dopant inlet 5, the bottom of dopant container 1 is provided with dopant outlet 6, and dopant inlet 5 is provided with A sealing cover 7 matched with the dopant inlet 5; a conveying ...

Embodiment 3

[0037] Embodiment 3: A method for improving the uniformity of axial resistivity of Czochralski single crystal silicon, which comprises the following steps: (1) preparation before the start of single crystal silicon pulling; (2) melting polysilicon raw material; (3) seeding Steps; (4) Steps of putting shoulders; (5) Steps of turning shoulders; (6) Steps of equal diameter; (7) Finishing steps;

[0038] (1) The preparation before the start of monocrystalline silicon pulling is specifically: before the start of single crystal silicon pulling, prepare a device for improving the uniformity of the axial resistivity of Czochralski single crystal silicon, which includes: a dopant container 1, a mass flow meter 2. Electromagnetic valve 3 and conveying pipe 4, the top of dopant container 1 is provided with dopant inlet 5, the bottom of dopant container 1 is provided with dopant outlet 6, and dopant inlet 5 is provided with A sealing cover 7 matched with the dopant inlet 5; a conveying pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com