Pretreatment method of epoxy type plasticizer production wastewater

A technology for producing wastewater and plasticizers, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. effect with alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

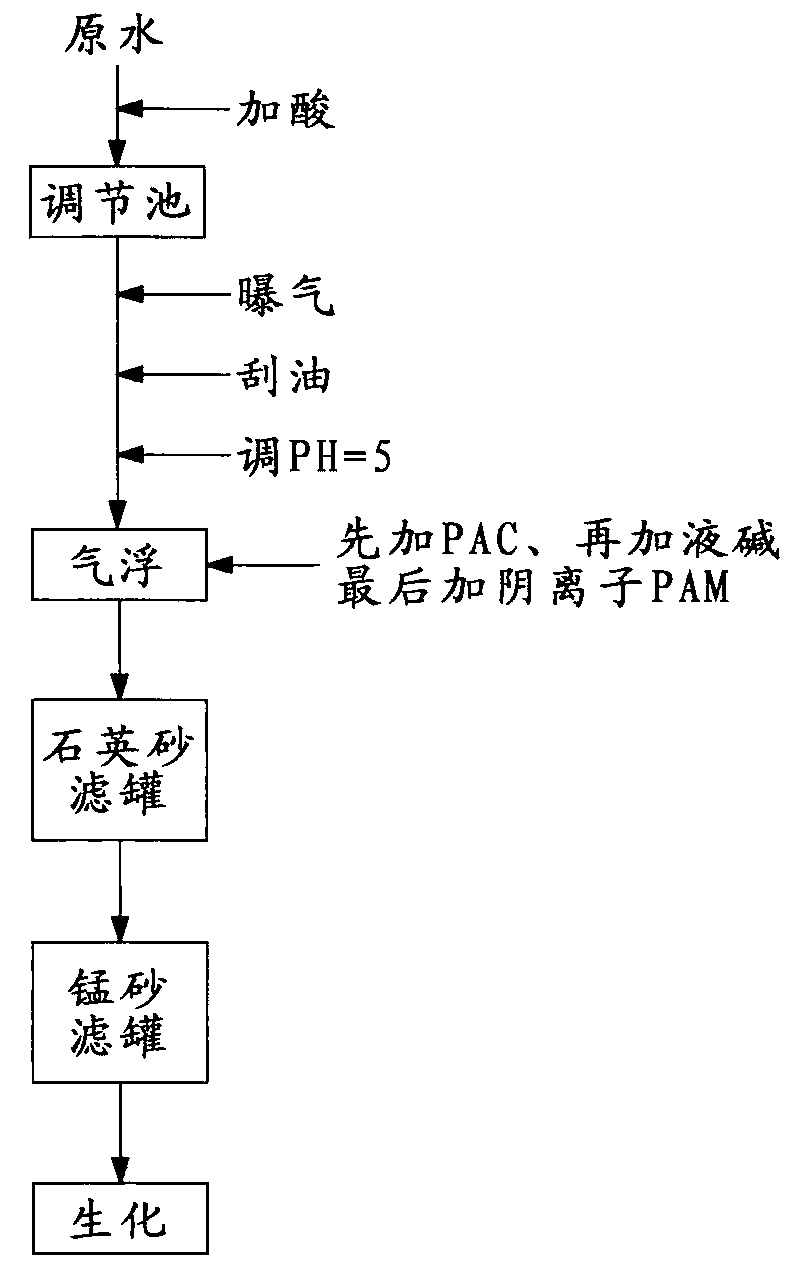

[0019] Such as figure 1 Shown, the concrete steps of the pretreatment method of epoxy plasticizer production waste water are:

[0020] (1) Inject wastewater from the production of epoxy plasticizers (grease content about 500ppm, hydrogen peroxide concentration 0.8%, pH value 4) into the grease trap, add 30% hydrochloric acid to adjust the pH to 3 for acidification and demulsification, after adjustment , Put the waste water into the regulating tank, turn on the fan to aerate the micropores to remove oil, the time of micropore aeration is 3 hours, then turn on the automatic oil scraper to skim the grease, after the oil is completely scraped, add an appropriate amount of sodium carbonate Adjust the pH value of the wastewater to 5 and enter the next step;

[0021] (2) Pump the waste water into the advection air flotation device. Turn on the air flotation device for air flotation treatment. The specific operating conditions of the air flotation treatment are: the pressure of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com